Carbon Additve Low Ash sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

Specifications

Carbon Additve Low Ash Sulphur for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additve Low Ash Sulphur for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Additve Low Ash Sulphur for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

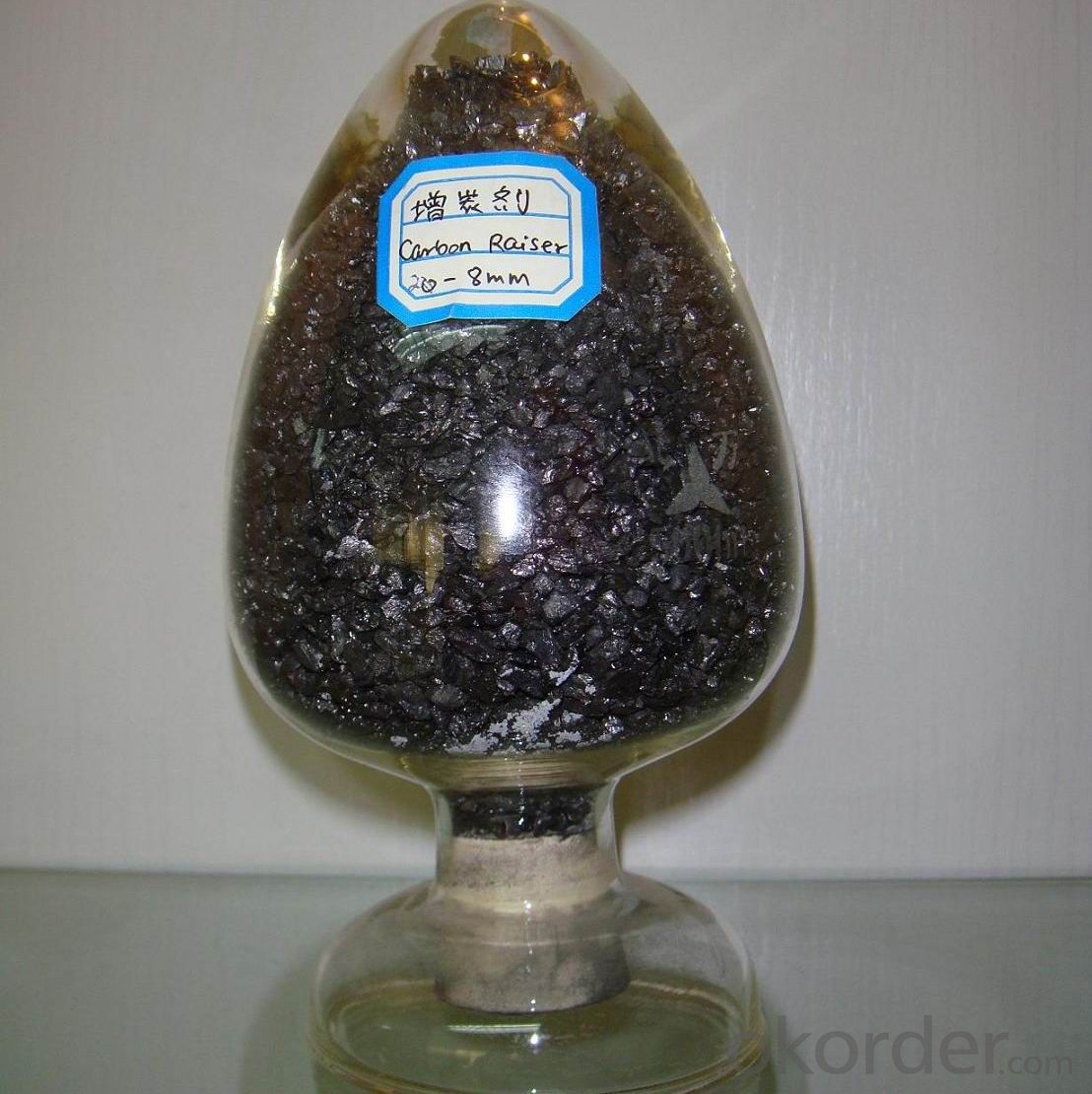

Image

Carbon Additve Low Ash Sulphur for Steelmaking

FAQ:

Carbon Additve Low Ash Sulphur for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additve Low Ash Sulphur for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: How does carbon impact the stability of desert ecosystems?

- Carbon can have both positive and negative impacts on the stability of desert ecosystems. On one hand, carbon is an essential element for all living organisms and is a key component of organic matter. It plays a crucial role in the processes of photosynthesis, respiration, and decomposition, which are vital for the survival and growth of plants and other organisms in deserts. Carbon dioxide, a form of carbon, is taken in by plants during photosynthesis to produce glucose and oxygen, providing the necessary energy for their growth. This promotes the stability of desert ecosystems by supporting primary productivity and the food web. However, the excessive release of carbon into the atmosphere, primarily through human activities such as burning fossil fuels and deforestation, has led to an increase in greenhouse gases, including carbon dioxide. This leads to global warming and climate change, which have significant negative impacts on desert ecosystems. Rising temperatures can alter the delicate balance of desert ecosystems, affecting the distribution and abundance of plant and animal species. Some plants may struggle to adapt to the changing climate, while others may benefit, leading to shifts in species composition and potential loss of biodiversity. Moreover, increased carbon dioxide levels can also affect the water availability in desert ecosystems. Elevated carbon dioxide levels can result in increased water-use efficiency in plants, allowing them to conserve water. This can be beneficial in water-limited environments like deserts, as it helps plants to survive under drought conditions. However, this can also lead to changes in water dynamics, impacting the availability of water resources for other organisms in the ecosystem. In summary, carbon is essential for the stability of desert ecosystems as it supports primary productivity and the functioning of food webs. However, the excessive release of carbon into the atmosphere contributes to climate change, which negatively impacts desert ecosystems by altering species distribution, reducing biodiversity, and affecting water availability. It is crucial to mitigate carbon emissions and promote sustainable practices to ensure the long-term stability and resilience of desert ecosystems.

- Q: Well, recently, the carbon cycle has suddenly come up with a lot of questions. What's the definition of carbon and light carbon? What are the characteristics, and what are the differences between the two?

- Light and heavy soil organic matter is divided according to the proportion of the isolates used in this study. The proportion of 1.7 is the proportion of < 1.7 for light fraction organic matter, the proportion of > 1.7 recombinant organic matter. The composition and decomposition of organic carbon in different components are significantly different. Light fraction organic matter by no solution complete plant residues and its fractions include a small amount of live microorganisms or their secretions, is susceptible to microbial decomposition and utilization characteristics, is very sensitive to climatic and environmental changes and agricultural management measures, is the active carbon pool in soil.

- Q: We need to make a poster... Of the 27 essential elements of the human body, I am in charge of carbon! I haven't found it for a long time! Who can help me? Urgent!!!!!!Can you find something very specific? Thank you

- It is well known that the basic units of life, amino acids and nucleotides, are derived from carbon skeletons. First, a carbon chain, a chain of carbon bound together, evolved into proteins and nucleic acids; then evolved primitive single cells, evolved worms, fish, birds, animals, monkeys, orangutans, and even humans.

- Q: Why is the solubility of carbon in austenite larger than that in ferrite?

- Its properties are similar to that of pure iron, and its plasticity and toughness are good, and its strength and hardness are low. It is usually massive or flaky in steel.The austenite structure is a face centered cubic lattice with a gap radius (0.414~0.225). Because of the larger size of the lattice gap, the solubility of carbon in gamma -Fe is relatively large. It has good plasticity.

- Q: What are the different types of carbon-based plastics?

- There are several types of carbon-based plastics, including polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene (PS), and polyethylene terephthalate (PET). Each of these plastics has unique properties and applications, making them suitable for various industries and products.

- Q: What are the properties of carbon nanotubes?

- Carbon nanotubes are a unique form of carbon with exceptional properties. They are incredibly strong and have a high tensile strength, making them stronger than steel but much lighter. They also have excellent thermal and electrical conductivity, allowing for efficient heat dissipation and electrical conduction. Carbon nanotubes possess a large surface area, enabling them to be used for various applications such as energy storage, water filtration, and drug delivery systems. Additionally, they exhibit remarkable flexibility and can be manipulated into different shapes and structures, making them highly versatile in nanotechnology and materials science.

- Q: How is carbon used in the production of fertilizers?

- Carbon is an essential component in the production of fertilizers. It is used in various forms such as organic matter, carbon dioxide, and carbonates. These carbon sources are utilized to enhance soil fertility, improve plant growth, and increase crop yield. Organic matter, such as compost, manure, and crop residues, contains carbon in the form of decomposed plant and animal materials. When added to the soil, these organic sources of carbon provide essential nutrients, including nitrogen, phosphorus, and potassium, to plants. They also improve soil structure, water holding capacity, and microbial activity, which are crucial for plant growth. Carbon dioxide (CO2) is another important carbon source used in the production of fertilizers. CO2 is captured from industrial emissions and incorporated into the production process. It is converted into various chemical compounds, such as urea and ammonium bicarbonate, which are widely used as nitrogen fertilizers. These fertilizers release nitrogen slowly, ensuring a steady supply of nutrients to the plants over an extended period of time. Additionally, carbonates, such as calcium carbonate, are used as neutralizing agents in fertilizers. They help to balance the pH levels of acidic soils, making them more favorable for plant growth. Carbonates also provide a source of calcium, an essential nutrient for plants, further enhancing their growth and development. In summary, carbon plays a crucial role in the production of fertilizers by providing essential nutrients, improving soil fertility, and enhancing plant growth. Whether in the form of organic matter, carbon dioxide, or carbonates, carbon is a vital component that contributes to the success of modern agriculture.

- Q: What are the properties of carbon-based rubber?

- Carbon-based rubber, known also as carbon black-filled rubber, possesses a range of important properties that make it highly desirable for a variety of applications. To begin with, carbon-based rubber demonstrates excellent elasticity and flexibility, enabling it to endure repeated stretching and compression without permanent deformation. This particular quality renders it ideal for the manufacturing of products like tires, gaskets, and seals. Moreover, carbon-based rubber exhibits exceptional resistance to abrasion and wear, ensuring its longevity even in harsh conditions and with prolonged use. This attribute proves particularly advantageous in applications where the rubber material experiences friction or constant contact with rough surfaces. Additionally, carbon-based rubber showcases remarkable resistance to various environmental factors. It boasts excellent resistance to ozone, sunlight, and weathering, making it suitable for outdoor applications where exposure to UV radiation and extreme temperatures is expected. Its resistance to chemicals and oils further enhances its versatility, enabling its use in industries such as automotive, aerospace, and manufacturing. Another notable property of carbon-based rubber is its electrical conductivity. This characteristic renders it an ideal material for applications that necessitate static dissipation or protection against electrostatic discharge, such as in electronic devices, conveyor belts, and industrial flooring. Furthermore, carbon-based rubber displays good adhesion to various substrates, allowing it to form strong bonds when employed in adhesive applications or as a lining material. Overall, the exceptional elasticity, abrasion resistance, environmental resistance, electrical conductivity, and adhesion capabilities of carbon-based rubber contribute to its status as a highly sought-after material.

- Q: What is carbon capture and storage?

- Carbon capture and storage (CCS) is a process that involves capturing carbon dioxide emissions from industrial sources, such as power plants, and storing them underground or using them for various purposes. It aims to mitigate the release of greenhouse gases into the atmosphere, helping to combat climate change by reducing carbon dioxide levels.

- Q: What are the meanings of carbon, graphite, burr, two cuts and four cuts in steel?.

- Carbon element; carbon is carbon steel, round steel, Primeton is end of carbon steel, which is common round, is construction steel.

Send your message to us

Carbon Additve Low Ash sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches