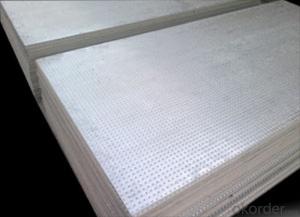

Calcium Silicate Board with Best Quality Standard Size

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

Can be used in washrooms as the ceiling, partition and backer boards. Additionally, Due to the features of fire prevention, thermal insulation, mildew proof and moisture proof, Bestinboards are also applicable to places where high security is needed.

Product Features:

1.Fire-retardant

2.Thermal-insulated

3.Mildew proof

4.Moisture proof

5.Sound insulated

6.Low moisture and water absorption

7.100% asbestos free and other hazardous substances.

Specification:

Size | Standard Size | Size:1220*2440*4/6/8/9/10/12/15mm |

Appearance | Surface | Surface:Un-Sanded/Sanded/Polished; |

Edge | Square/Recessed/ | |

Physical Properties | Density | 1.2-1.3g/cm3 |

Bending Strength | Cross > 16Mpa Parallel 60-70Mpa | |

Moisture Movement | <0.20%< td=""> | |

Water Absorption | < 0.1% | |

Water Contain | <6%(Under EMS condition) | |

Thermal Conductivity | 0.12-0.15 w/(m •k) | |

Non-combustibility | GB 8624-2006 Grade A1,CE EN 12467:2012 Grade A1 | |

Water Impermeablility | Traces of moisture appeared on the under surface of the sheet,but no formation of drops of water on the underside of the sheet after 24 hours. | |

Freeze-thaw | Not have cracking and layering after freeze-thaw cycles 25 times. | |

Application | Interior Ceiling,Interior Patition, Bottom Liner | |

Products Warranty | More than 20 years |

Raw Material | Content |

Cement | 44 % |

Quartz | 44 % |

Natural Fiber | 8 % |

Suspension | 4 % |

Composition of Finished Product | Content |

Crystalloid of Calcium Silicate | 52% |

Quartz | 30% |

Calcium Carbonate | 10% |

Cellulose | 8% |

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate:<0.19% (GB/T7019-1997)

Description:

1.Superposition joint part between main carrier and vice carrier or vice carrier and carrier is called point lap.

2.It uses lap structure to assembly, connection between joints dovetail very well. The joint face unknits and have a nice appearance.

3.There is a barb at the vice carrier joint, it can avoid loosing and falling from the infection of outside force.

4.Soleplate of main and vice carrier is zincification armor plate, which meets the national GB standard demand. We use baked paint zincifcation armor plate as baked paint panel,whoes capacity of zincification is high. It meet the national GB standard demand.

5. Raw Meterial is galvanized steel with 80-100g/sqm

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: We're tiling our basement. The floor is plain concrete. Do I need to put a layer of plywood, then a layer of cement board, then the tiles, or do I just need a layer of cement board then the tiles?

- If the concrete is solid without big voids or decomposing or something like that I would say you can just apply adhesive directly to concrete and start setting your tile. But I'm The Door Guy.....You should probably hear from the tile guy!! Good luck!

- Q: Decorative fire board environmental protection? How to choose to buy environmentally friendly decorative fire board?

- Application of special coating process, in the sheet surface coating high-performance environmentally friendly coatings, the formation of high-quality fire environmental decorative panels. Known as green, low carbon, energy saving, environmental protection of the new decorative plate, instead of the traditional wood sheet, marble, tiles and other decorative materials, and the surface wear easy to clean, impact resistance, color stability, moisture and weather resistance.

- Q: Hi I was thinking of bonding Hardiflex Fiber Cement Board to a Wood Chipboard, I want to know if it is possible to bond this two things using D3 Wood Glue?Will They be bonded with same strength as wood to wood?Thanks!

- The problem is that the chipboard may not be rated to support the cement board. If it has flex, the cementboard will crack and so will the tile. Go back to Home Depot.

- Q: i am going to be installing tile in my bathroom as a tub surround.i am wondering what backer board is needed. if i am using a membrane such as kerdi, is drywall a good enough backer or do i need cement board. if i need cement board, do i need the membrane? what products do you suggest for best installation. i will also be doing a walk in shower. are there any differences to be aware of compared to the tub surround shower style.

- I am assuming you are going with ceramic tile. If that is the case then you do not need fiberboard. Just tile right to the concrete floor. As for the crack either fill it in or use a product called RedGaurd. RedGaurd is a rubberized product that when applied over the crack will expand and contract and thus keep the crack covered. You can apply RedGaurd then put mortar right over it.

- Q: I am building a shower in the basement of a 50 year old house in Michigan. I am using cement board (backerboard) for the sides which I framed in. The back of the shower is the existing cement block wall. Can I apply the mortar and tile to the cement block wall just as I would for the cement board? Will there be any problems with it stinking? The wall will get chilly during the winter.

- Installing Tile On Concrete

- Q: how do I lay cement board on a concrete floor with out screws?

- If the concrete floor is smooth, you can place the tiles on the concrete. The thinset will do the job. If the concrete is rough, try concrete refinisher. It's easy to use and will give a smooth surface. Hardi backer or cement board should be screwed to the floor. Use a masonry bit to drill the holes. Be sure to tape the seams and then proceed with your tile. Using a high speed drill will drill the holes quickly and easily. I do this for a living.

- Q: What is the best fixation screw in the cement board?

- With AB glue, vigorously glue These two kinds of glue is a strong adhesive, durable adhesive

- Q: i am using cement board to cover a wood floor before laying tile. the last time i used it, i cut it with a circular saw (what a mess) dust everywhere. is there a better way??

- Not that I know of. hate the stuff. It works well though. I had to use a skilsaw and score it then jump up and down on the discard piece til it broke. A real pain in the butt.

- Q: Is a vapor barrier needed behind cement board in a shower?

- on an exterior wall you will need vapour barrier

- Q: i live in a country where houses are made with bricks..but i made my house just like in USA , but there is one only problem i need cement board to finish the bathroom , since we don't have cement board here for sale , and i can't afford import from USA , i was wondering that i can make it , i'm sure that i can make it , but i just need to know how to prepare de cement i would be appreciated if anyone help me thanks

- cement board or backer board, despite its name, isnt a board with cement on it. as far as i know, its agregate cement with glass meh fibre on top of it. i would not make it yourself. since its meant to protect your bathroom from water damage, i wouldnt take the risk. do you have green board (waterproof drywall) that would be another option. this dosent really solve your problem, but a bettrer product to use instead (or as well as) backer board, would be ditra. you can sheet your bathroom in 3/4 plywood anywhere your going to tile, apply thinset, and lay down the ditra mats (following al instructions). then you can tile over it with thinset, and grout it and you have a very effective waterproofing system. its expensive, but it will last a lifetime and you will never have water problems. they make other products ditra products for walls, floor and even for walk in showers (curbs).

Send your message to us

Calcium Silicate Board with Best Quality Standard Size

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 600 pc

- Supply Capability:

- 20000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords