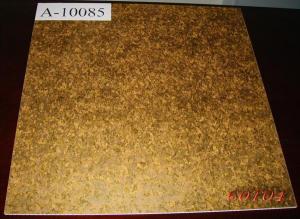

Standard Size Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

suspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding

Calcium Silicate Board is mainly made of siliceous and calcareous materials as major and natural cellulose reinforced, forming in Hatschek process and high pressure (7000 tons and fumigation(in autoclave for 24 hours),Which has the advantages ofhigh strength, light weight, anti- freeze, water-resist, fire-proof, damp-proof, sound-absorption , no distortion and no radiation Used assuspended ceiling, partition, heat insulating board, base plate, external wall panel, exterior wall cladding, paneling, flooring, back-liners, skirting lines, prefabricated structures, door shutters

Application: partition & ceiling in office, supermarket, hotel, hospital, gymnasium, school, stations; interior wallboard in carriage, marine structure, shipping vessel which need fire-proof, heat insulation and damp-proof

Materials: Tobermorite, lime, Quartz sand, wood fiber

Fire-proof rate: A-class incombustible (GB8624-1997)

Incombustibility: 240 minutes (GB/T9978-1999)

Density: 1.2-1.4g/cm3

Moisture: <10%

Heat conduction: 0.24W/MK (Jc/t564) Average

Sound-absorption: 45db (GBJ75-84)

Anti-bend strength: >15MPa (GB/T7019-1997)

Moisture movement rate: <0.19% (GB/T7019-1997)

- Q: Can silicon calcium board be used for roof insulation?

- Silicon calcium board, also known as gypsum composite board, which is a porous material, with good sound insulation, thermal insulation properties, in the case of indoor air humid to attract water molecules in the air, air drying, but also the release of water molecules, Appropriate to adjust the indoor dry, humidity, increase comfort. The

- Q: How to build calcium silicate board mill, how much money

- Specific raw materials are plant fiber mineral fiber (asbestos) cement, limestone quartz sand, etc. according to the scale of investment of millions to tens of millions.

- Q: Who can tell me silicon calcium board, calcium silicate board, high crystal board, paperless gypsum board, glass fiberboard in the end what is the difference

- Silicon calcium board and calcium silicate board are also two different materials. Silicon calcium board is mainly composed of gypsum, and calcium silicate is composed of quartz, mica, wood fiber and other components. Followed by the use: calcium calcium board is mainly used for indoor ceiling, and it also high-grade, mid-range, low-grade distinction, the best is solid silicon calcium board, moisture, fire, pollution, low carbon, clean surface, durability it is good. The calcium silicate board can be used for indoor and outdoor partitions, ceiling, surface decoration, firewall, fire ceiling, steel fire, high temperature insulation and many other environments, calcium silicate board also has good or bad points, Harmless to the human body, poor raw materials sucks, containing asbestos, carcinogenic. So choose a good silicon calcium board is very important, only work rigorous, good reputation, but also extremely responsible for the manufacturers will be in accordance with the standard production of non-toxic refractory quality excellent plate.

- Q: Calcium silicate board why wet weather will appear scarred

- Ceiling keel installation interval is too large: part of the keel of the mechanical properties did not meet the national standard indicators, the plate after the installation of a greater degree of deformation. Keel and plate when the connector is not staggered, it is difficult to avoid stress concentration. The whole plate is installed in different directions at the same time on the screw fixation, so that the sub-stress within the plate easy to crack.

- Q: Indoor compartment with calcium silicate board or gypsum board is good?

- When decorating, the use of gypsum board more, calcium silicate board rarely used, generally only in the bathroom which will encounter. Gypsum board to do the wall, the construction is convenient, the price is relatively cheap.

- Q: Gypsum board, Etter board, calcium silicate board, mineral wool board physical properties of what is different, the kind of hotel for the ceiling is more appropriate?

- Usually with gypsum board it. The

- Q: Calcium silicate board above the watermark is how to cause

- Yellow whirring, and generally the reasons for the use of kraft paper fiber, dry after generally not anti-color, but I suggest you use sanded calcium silicate board, such problems will be less.

- Q: What kind of ceiling does the open kitchen do? Is it the same as the lobby to do the calcium silicate board, or do it?

- The kitchen is usually fitted with an aluminum gusset plate or an integrated ceiling

- Q: Calcium silicate board ceiling of the joints with what will not crack it?

- First analyze the cause of cracking. Calcium silicate board ceiling cracking for three reasons: First, keel problems. If the use of light steel keel, the thickness of more than 0.8 mm, if the thickness of the wood keel to 3.5 cm or more. To ensure that the seams on the edge of the screw effectively locked in the same keel. Second, leave the seam problem, you must ensure that more than 5 mm left seam.Three is the seam material problem, to ensure that the joints in the material into the powder and cellulose construction If the thickness of more than 6 mm, the best hanging plastic several times hanging, and so on the layer of glue dry and then hang a layer of glue, dry after hanging on the glue and other joints with dry after the best and then linked to white plastic The last seam belt, so that the dry environment in the north will not crack in the south even more problematic.

- Q: Is it harmful to calcium carbonate on home improvement?

- Asbestos content of 100% without asbestos, HBC223-2005 "lightweight wall panels" Radioactive Class A materials, production and marketing and use of unrestricted. In line with GB6566-2001 "building materials radionuclide limit" Non-combustible Class A incombustibility, in line with GB8624 "building materials combustion performance grading method" High-performance, high strength, fire, water, moisture, noise, insulation, insulation, shock, impact resistance, anti-aging, corrosion resistance, pest control, easy processing, easy decoration, stable performance.

Send your message to us

Standard Size Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords