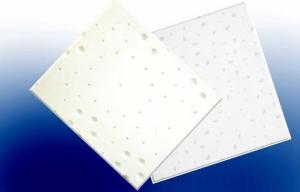

High Quality Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

high density , strength and toughness, surface smooth

can meet higher requirement for coating

easy for surface processing

| performance | |||

| performance index | standard index | test result | |

| density(g/cm³) | 1.4<D≤1.7 | 1.64 | |

| water absortption | ≤25 | 17.8 | |

| wet expansion | 0.23 | 0.15 | |

| incombustibility | Incombusitility class A1 | ||

| water penetration | back sie without water drop after 24hrs | ||

| modulus of rupture | air dried condition | ≥18 | 20.1 |

| saturated condition | ≥14 | 15 | |

| frost-resistance | no layer no cracks after cycles under freezing and thawing | ||

| radioactivity | decorative materials class A | ||

| asbestos | 100% free of asbestos | ||

application" exterior decoration panel; integrative facade panel for exterior wall thermal insulation;interior wall decoration panel;flooring;subway,tunnel,baseboard,outdoor furniture.Thinner lining board for stone.

- Q: Ceiling with gypsum board or calcium silicate board?

- The shape of the ceiling less With calcium silicate board. Hardness. Waterproof and waterproof. Not easily deformed. Fire performance is better. 2 are not much price.

- Q: Calcium silicate board wall can be directly putty putty

- If the direct application of calcium silicate board (plate) on the batch of putty powder prone to fall off (gray) phenomenon, we must first primer, it is recommended to use the home of the German brand brackish putty to scratch again (TB) To be dry and then approved scraping putty powder.

- Q: Paper gypsum board, calcium silicate board, silicon calcium board difference

- Gypsum board is built with gypsum (that is, CaSO4) as the main raw material, mixed with the right amount of additives (adjust the rate of condensation) and fiber to do the core, with a special plate for the face, the processing of the plate. High, impatient

- Q: Silicon calcium board and mineral wool board difference between the price is the price, and the advantages and disadvantages of the material

- Of course, the price is much lower than the mineral wool board, silicon calcium board weight is much heavier than the mineral wool board weight, but the installation is not different, need light steel keel and paint keel. Mineral wool board generally ordinary price of 20 yuan, silicon calcium board price of 10 yuan or so.

- Q: Bath area top need to paste mosaic, what material ceiling material to ensure that no deformation? Cement board Calcium silicate board

- The keel used in the ceiling must be strong, will not be deformed, if the keel deformation, then the top will be affected.

- Q: What is the difference between aluminum-plastic plate and calcium-plastic plate? How to use it in those places?

- Aluminum-plastic plate: it is a high-pressure polyethylene as the substrate, adding a lot of containing aluminum hydroxide and the amount of flame retardants, the plastic, hot, foam and other processes made. This kind of sheet light, sound insulation, heat insulation, moisture. Mainly used for ceiling, wall surface material. This board will change color for some time. Calcium plastic plate: it is a high-pressure polyethylene as the substrate, adding a lot of light calcium carbonate and a small amount of additives, the plastic, hot, foam and other processes made. This kind of sheet light, sound insulation, moisture, moisture. Mainly used for ceiling surface material.

- Q: Calcium silicate board sticky rock wool sandwich sandwich board what glue stick to live?

- This problem is very good solution, ah, with MPU-20-type one-component polyurethane adhesive can be bonded.

- Q: Calcium silicate board fire board can do air conditioning ducts do

- Yes, apply 93 decorative quota: 3-84 fire board attached to the wood base layer (the most appropriate) other related: 2-150 fire board wood keel base wall wall skirt 2-160 fire board wood keel base beam and column.

- Q: Calcium silicate board ceiling of the joints with what will not crack it?

- First analyze the cause of cracking. Calcium silicate board ceiling cracking for three reasons: First, keel problems. If the use of light steel keel, the thickness of more than 0.8 mm, if the thickness of the wood keel to 3.5 cm or more. To ensure that the seams on the edge of the screw effectively locked in the same keel. Second, leave the seam problem, you must ensure that more than 5 mm left seam.Three is the seam material problem, to ensure that the joints in the material into the powder and cellulose construction If the thickness of more than 6 mm, the best hanging plastic several times hanging, and so on the layer of glue dry and then hang a layer of glue, dry after hanging on the glue and other joints with dry after the best and then linked to white plastic The last seam belt, so that the dry environment in the north will not crack in the south even more problematic.

- Q: Two layers of calcium silicate board in the middle of what kind of sound insulation board

- Calcium silicate composite rockwool sound insulation board, but now with less, mainly out of environmental protection, the use of area considerations.

Send your message to us

High Quality Calcium Silicate Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords