C10 PVDF-PE Prepainted Aluminum Coil with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Aluminium Coil with PVDF Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the AA5052 Aluminium Wire:

Wood grain-coated aluminum sheet with PVDF and can be used for many fields such as roofing, ceiling, curtain wall, lamp decoration, aluminum composite panel, honeycomb plate, doors and furniture.

Adapts aluminum coil and use best imported paint, composition contains 70% PVDF.

Technology is four coating and two baking.

Surface of products is smooth and dry.

Color is uniform.

Resist UV in air and corrosion.

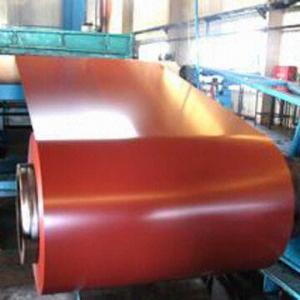

Images of Prepainted Aluminium Coil with PVDF:

Prepainted Aluminium Coil with PVDF Specification:

| product | alloy | temper | size (mm) | ||

| thinckness | width | ||||

| aluminum coil/Color coated al coil/sheet with PE or Pvdf | 1070 1060 1050 1145 1235 1035 1100 1200 3A21 3003 3103 8011 | H18 H14 H16 H22 H24 0 | 1.0-4.0 | 60-1500 | |

FAQ of Prepainted Aluminium Coil with PVDF:

a) What's your process of this type aluminium?

Decoiler → Accumulator→Tension Leveller →Acid&Alkali Cleaner → Rinse →Conversion Treatment → Priming coater →Infrared Curing Oven →Main coater →Floatation Curing Oven →Strippable Film Applicator → Exit Accumulator →Recoiler

b)Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are 101 aluminum sheets suitable for aircraft manufacturing?

- Yes, 101 aluminum sheets are suitable for aircraft manufacturing.

- Q: Are aluminum sheets suitable for roofing?

- Yes, aluminum sheets are suitable for roofing. Aluminum is a popular material for roofing because it is lightweight, durable, and resistant to corrosion. It is also non-combustible, making it a safer option for roofing. Aluminum sheets are easy to install and maintain, and they can withstand harsh weather conditions such as heavy rain, snow, and wind. Additionally, aluminum is a sustainable material, as it is 100% recyclable, making it an environmentally friendly choice for roofing. Overall, aluminum sheets provide a long-lasting and reliable roofing solution for both residential and commercial buildings.

- Q: Can aluminum sheets be anodized for corrosion protection?

- Yes, aluminum sheets can be anodized for corrosion protection. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This oxide layer is highly resistant to corrosion and provides a durable and long-lasting protection. Anodizing can be done on various aluminum products, including sheets, to enhance their corrosion resistance, improve their appearance, and increase their lifespan. The process involves immersing the aluminum sheet in an electrolyte solution and applying an electric current, which causes oxygen ions to bond with the surface of the metal, forming the protective oxide layer. Anodized aluminum sheets are widely used in industries such as aerospace, automotive, construction, and electronics, where corrosion resistance is crucial.

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation to some extent. While aluminum is not the best material for soundproofing compared to others like rubber or foam, it can still provide some level of sound insulation when used correctly. Aluminum sheets can be installed as a barrier or partition in walls, ceilings, floors, or other surfaces to reduce the transmission of sound waves. However, it is important to note that additional soundproofing materials or techniques might be necessary to achieve optimal results.

- Q: Is aluminum suitable for projects with heavy traffic or frequent use?

- <p>Yes, aluminum sheets can be used in projects that involve high levels of traffic or heavy use. Aluminum is a lightweight, durable, and corrosion-resistant material. It can withstand significant wear and tear, making it suitable for high-traffic areas. Additionally, aluminum is easy to maintain and can be recycled, which is beneficial for long-term projects. However, it's important to consider the specific grade of aluminum and its thickness to ensure it meets the required strength and durability for your project.</p>

- Q: Can aluminum sheets be used for honeycomb panels?

- Yes, aluminum sheets can be used for honeycomb panels. The lightweight yet sturdy nature of aluminum makes it a popular choice for constructing honeycomb panels, which are commonly used in aerospace, automotive, and construction industries for their strength-to-weight ratio and structural integrity.

- Q: What is the typical torsional strength of aluminum sheets?

- The typical torsional strength of aluminum sheets can vary depending on various factors such as the alloy composition, thickness, and manufacturing process. However, in general, aluminum sheets have a good torsional strength compared to other materials. Aluminum alloys commonly used in sheet form, such as 6061-T6 and 5052-H32, have torsional strengths ranging from approximately 22,000 to 40,000 pounds per square inch (psi). These values represent the maximum amount of torque that can be applied to the aluminum sheet before it permanently deforms or fractures. It is important to note that torsional strength is just one aspect of the overall mechanical properties of aluminum sheets. Other factors like tensile strength, yield strength, and elongation also play significant roles in determining the suitability of aluminum sheets for specific applications. Therefore, when selecting aluminum sheets for a particular torsional application, it is essential to consider the specific requirements and consult with material suppliers or engineers to ensure the chosen aluminum sheet meets the desired torsional strength requirements.

- Q: Is aluminum sheet magnetic?

- Incorrect, aluminum sheets lack magnetic properties. As a non-magnetic metal, aluminum neither attracts nor repels magnetic materials due to the absence of magnetic elements within its composition. Consequently, attempting to affix a magnet onto an aluminum sheet will prove futile, as it remains unaffected by magnetic fields.

- Q: Are aluminum sheets suitable for bulletproof applications?

- No, aluminum sheets are not suitable for bulletproof applications.

- Q: Can aluminum sheets be etched or engraved?

- Yes, aluminum sheets can be etched or engraved. Etching or engraving on aluminum sheets is a process that involves removing some of the material from the surface using acid or a high-powered laser. This can be done to create intricate designs, patterns, or even text on the aluminum sheet. The etching or engraving process can be used for various applications, such as signage, decorative pieces, or industrial parts. The resulting etched or engraved design on the aluminum sheet can be further enhanced by adding color or other finishes to create a desired look.

Send your message to us

C10 PVDF-PE Prepainted Aluminum Coil with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords