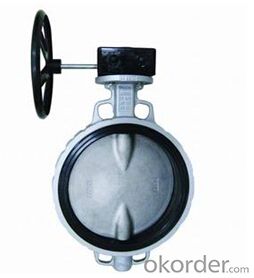

Butterfly Valve Turbine Type DN250 with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 20000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required.

2.Main Features of the Manual Wafer Butterfly Valve

1.Simple and compact construction. Small in size and light in weight. Easy transportation, installation and maintenance.

2. Quick 90 degrees on-off operation. Minimized operating torque ,energy saving.

3. Excellent sealing performance with no leakage. Long service life.

4. Wide selection of materials ,applicable for various media..

5. Flow curve tending to straight line. Excellent regulation performance.

6. Bubbles-tight sealing with no leakage under the pressure test

7. Wide selection of materials, applicable to various mediums

3.Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

Size: DN50-DN1000

End flange: ANSI B 16.1,EN1092,AS2129

Face to face: ANSI B 16.10

Top flange: ISO 5211

Normal pressure: PN1.0/1.6MPa(150/200PSI)

Body: CI/DI/WCB/ALB/CF8/CF8M

Disc: DI/ALB/Rubber lined Disc/1.2501/1.4529/CF8/Hastelloy Alloy/Monel

Suitable temperature: -10~120

Medium: Fresh water, sewage, sea water, air, vapor, food, medicine, oils, alkalis, salt etc.

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

- Q: I am trying to replace a leaky valve stem. And I didn't know how to get to the valve core and when I get there how do I change it? The charge is recovered. It is a 2000 Impala. Thanks in advance.Noah

- Schrader Valve Core

- Q: Between these two Blow off valves around the same price, what would be the best choice for a pt cruiser.

- The Mopar Performance blow off valve is really going to be your best bet if the two are roughly the same price. The reason I say that is because the Mopar unit is designed to fit onto that car, therefore it is engineered to release excess pressure at a safe level for that engine. The Greddy unit is also going to typically require modification to make it fit and function properly. Unfortunately, what they don't tell you about universal units is the reason they are universal is because they don't fit anything until you make them to fit, you just have enough material and hardware to get creative with it. If you are looking to extensively modify your engine, then it may benefit you to go with the universal unit and just wait until you have your piping cut exactly the way you want it, this may give you better location or clearance using the aftermarket unit, but otherwise like I said, I would go with the factory performance BOV. If you have any further questions about your cruiser, please feel free to email me, I have had a cruiser for a couple of years now and have also done lots of customizing to cruisers for friends.

- Q: Im looking for a new BBb tuba. i would like six valves at 4+2. but if not looking for 6 valve BBb tuba

- Better get busy with that search engine, then!

- Q: My car has been sputtering and hesitating when I hit the gas. My friend's boyfriend says it is a bad erg valve does that sound right?

- An EGR valve being open will cause mostly idle problems and light throttle/initial take-off problems...mostly when you have a high manifold vacuum is when you end up with problems because of a sticking EGR valve. Just remove the valve and clean it by soaking it in something like B-12 Chemtool. I can garuntee you that valve is probably disgustingly full of carbon depending on the year.

- Q: i am hearing tapping on top under of vale cover sound like valve need adjusting

- time to change oil, use thicker oil or yep, adjust valves. not a monstrous project but time consuming. Need torque wrench, valve cover gasket and shim kit to adjust. It's a pain as u have two nuts on each valve adjustment rocker bolt. tightening causes the lower one to drop sometimes so u may find yourself adjusting the valves 2-3 times each. I did it on my old Acura with 78K miles. ran smoother. i dropped in a pulley kit and cold intake as well but afterwards. the head was real clean as I change oil regularly. I had tapping even after changing the knock valve so I knew the valve job was needed.

- Q: Im 17 with a Bicuspid Aortic valve and hypertension (around 160/85). Only other family member with teenage hypertension is grandfather. Im on 2 different types of hypertension medication which only brings blood pressure down to 138/75. It still jumps to 157/85 on medication. I have leakage of my valve that has not gotten worse or better since starting the medication (first checked in September, medication started in Novemberish, now April). No stenosis yet. Any idea what im looking forward to in next couple years? Or is this stuff spontaneous?

- Hey okorder /... I am also posting a page from the American Heart Association about High Blood Pressure hopefully you'll read about it some and begin to learn about some of the ways you might help keep yours lower with food and watching some things like sodium (salt) keeping it around 1500mg a day (2/3 of a teaspoon) on all your food... limiting soda or pop and energy drinks and trying to stick with 8 8 oz glasses of water, fruits and veggies and Good stuff..

- Q: My brother is 32 years old.He has an enlarged heart ,a murmur,high blood pressure and heart regurgitation.He may be having the valve replacement surgery.I was wondering if anyone has had these things wrong with them and had the valve surgery and did well afterwards.Any information would be very much appreciated.

- Which valve is getting replaced (there are 4 in the heart)? Will he be getting a man made one (which will require life long blood thinners but are also very durable) or a pig valve (no need for blood thinners but won't last as long) ? Many people get valve replacements and it makes them feel wonderful afterwards.... make sure you find out about exactly the surgery he's having so you know... but I'm sure he'll be fine.

- Q: I am looking for a full valve guitar amp for around ?300.It needs to be loud enough to play with a quietish drum kit.Currently i have looked at an epiphone valve senior in both and combo and cab and head form. i have also looked at some smaller amps such as the vox ac4 but am a bit worried about its small size. any advice would be greatly welcome. many thanks in advance.

- Well I have the Valve Jr. and the AC4. The AC4 is a good sounding amp, but even though it is only 1 watt less, the Valve Jr. is much louder. The AC4 is a great practice amp but not enough to jam with a drummer unless he is pretty quiet and you really crank the amp. Never heard one of the new Valve Sr. models but with all of the goodies they added it should sound really good. I had my Jr. modified but it still doesn't have all the cool stuff the Senior has. I think you would really like the Epiphone and at 20 watts you will be more than loud enough. My 5 watt Jr. will get very loud. All I own are low watt class A valve amps, it's the only way to fly!! The Marshall Class 5 might be worth looking at also.

- Q: So outside we have a gas grill. There is a valve to turn when you want to use it. U can only hear the gas going when u turn the burner knobs but say u left the valve open and no knobs turned at all for 5 hours is gas escaping or does it only escape when the grills knobs are turned? Thanks

- The valves on the grill itself are the ones that allow the gas to flow. As long as you have no leaks between the main valve and the grill valves, no gas will flow when the valves on the grill are turned to the off position.

- Q: emission control valve toyota camry

- and the question is ?????????

Send your message to us

Butterfly Valve Turbine Type DN250 with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 20000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords