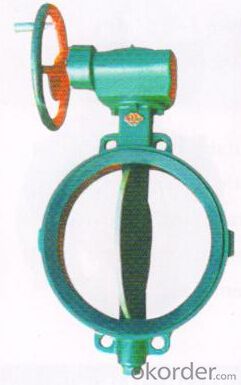

DN300 Turbine Type Butterfly Valve with Hand wheel BS Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General valve using the market long-term, widespread Water Leakage, rust phenomenon, soft sealing gate valve produced by the introduction of foreign advanced technology of the enterprise. To overcome the poor sealing gate valve, general elastic fatigue, rust and other defects. Soft sealing gate valve is a traditional valve replacement products, the compensation effect of using flexible gate produce small deformation, achieve good sealing effect, the valve has a light switch, reliable sealing, good elastic memory and long service life and other significant advantages, can be widely used in water, sewage, construction, food, medicine, metallurgy, electric power, textile, energy systems, fluid pipeline regulation and closure devices as.

The characteristics of:

- flat style seat

The traditional control valve often pass after washing due to foreign objects such as stone, wood, cement, paper, and other debris deposited on the valve at the end of the groove. Close but not close easily lead to the formation of Water Leakage phenomenon, the lower part of the soft sealing gate valve with water using the same flat design, easy to siltation caused by debris, the fluid unimpeded.

And the overall package glue

The valve plate is made of high-quality rubber overall, the outsourcing of plastic, making the domestic first-class rubber vulcanization vulcanization after the valve plate to ensure accurate geometry, and the rubber and ductile iron gate is connected firmly, not easy to fall off and good elastic memory.

And corrosion resistance

The valve body adopts epoxy coating powder, can prevent the corrosion and rust, and can be used for sewage systems.

And not easy to break

Traditional cast iron garden gate often hit foreign objects, collision or overlap caused by the fracture phenomenon. Because the valve to switch to ductile iron, this is the case already significantly reduced.

Three "O" ring seal

As the valve stem with three "0" ring ring seal design, can reduce friction when the switch is greatly reduced, Water Leakage phenomenon and can cut off the water supply construction not replace sealing ring.

And help to drink

Due to the internal body to non-toxic epoxy resin coating, gate of the inner and outer surfaces are completely coated with rubber and can not rust or corrosion of water available to drink.

- Casting valve

Valve body casting, precise geometry makes the body without any internal finishing to ensure that the valve seal.

And light weight

The valve is made of ductile cast, lighter in weight than conventional gate weight about 20%-30%. Convenient installation and repair.

Overview:

General valve using the market long-term, widespread Water Leakage, rust phenomenon, soft sealing gate valve produced by the introduction of foreign advanced technology of the enterprise. To overcome the poor sealing gate valve, general elastic fatigue, rust and other defects. Soft sealing gate valve is a traditional valve replacement products, the compensation effect of using flexible gate produce small deformation, achieve good sealing effect, the valve has a light switch, reliable sealing, good elastic memory and long service life and other significant advantages, can be widely used in water, sewage, construction, food, medicine, metallurgy, electric power, textile, energy systems, fluid pipeline regulation and closure devices as.

The characteristics of:

- flat style seat

The traditional control valve often pass after washing due to foreign objects such as stone, wood, cement, paper, and other debris deposited on the valve at the end of the groove. Close but not close easily lead to the formation of Water Leakage phenomenon, the lower part of the soft sealing gate valve with water using the same flat design, easy to siltation caused by debris, the fluid unimpeded.

And the overall package glue

The valve plate is made of high-quality rubber overall, the outsourcing of plastic, making the domestic first-class rubber vulcanization vulcanization after the valve plate to ensure accurate geometry, and the rubber and ductile iron gate is connected firmly, not easy to fall off and good elastic memory.

And corrosion resistance

The valve body adopts epoxy coating powder, can prevent the corrosion and rust, and can be used for sewage systems.

And not easy to break

Traditional cast iron garden gate often hit foreign objects, collision or overlap caused by the fracture phenomenon. Because the valve to switch to ductile iron, this is the case already significantly reduced.

Three "O" ring seal

As the valve stem with three "0" ring ring seal design, can reduce friction when the switch is greatly reduced, Water Leakage phenomenon and can cut off the water supply construction not replace sealing ring.

And help to drink

Due to the internal body to non-toxic epoxy resin coating, gate of the inner and outer surfaces are completely coated with rubber and can not rust or corrosion of water available to drink.

- Casting valve

Valve body casting, precise geometry makes the body without any internal finishing to ensure that the valve seal.

And light weight

The valve is made of ductile cast, lighter in weight than conventional gate weight about 20%-30%. Convenient installation and repair.

- Q: anyone know where this switch or whatever you want to call it is located. the car was in accident. so it wont start but cranks. so i wanted to know where the shut off valve is located for the fuel. thanks.

- 2007 does not have a shut off valve. Sounds as if some one has used a non programed key Nissan Imobilizer has detected the aftermarket non programed or key with chip embedded in the key has failed. After 4 attempts the car turns on lock mode and it is tow truck time. Gather up all the keys you have they all have to be reprogramed. And it is a good time to have two complete sets of keys and remotes money allowing of course. Only computerized lock smiths and Nissan dealerships can introduce keys. Is there a red light that looks like a car with a key lighting up when you attempt to start the car?

- Q: where is the oil pressure relief valve at in a 2003 ford focus

- Oil Pressure Valve

- Q: large veins contain one way valves, which keep the blood flowing in one direction. why dont large arteries need similar valves?

- The aorta and the pulmonary artery both start at valves from the heart, but I don't know if you could say they have valves. A lot of arterial flow is regulated by smooth muscles which constrict to direct flow to other areas. These are a kind of valve too.

- Q: I've found a little beemer that's only $800. I would like to have it as a 2nd car that I'll use in case something's wrong with my main car to loan maybe once or twice weekly to my neices (16 yr. old twins). The seller says it needs a valve job. My question is, will the valve job cost me more than the car?

- You bet it will! A valve job may uncover valve guides that are out of specification. In which case the old guide hole will have to be drilled out and the guide hole honed, new bronze / nickel or hardened steel guides pressed back in. An ordinary valve job is relatively straight forward and easy but the labor involved with the tear down a new head and valve cover gasket without valve guide repair will run nearly $1,000 at a BMW dealership and 20 -30% less at a private mechanics shop. Most private mechanics AND dealerships do not do the actual valve job. The cylinder head with the valves are sent out to an automotive engine machine shop where the actual work is done. The dealer or private mechanic does the disassembly and reassembly of the head back on the block and gets the car running again.

- Q: I was wondering if the pressure relief valve can be vented right under the house or does it have to be ran to the outside of the house. Also is there another method such as a catch pan that I can employ? I live in Washington.

- Most codes state that it must be vented to the outside.Check with your city code enforcer or county office.

- Q: Where is the illusive heater control valve?

- The only valve i could think you are referring too would be the vacuum control on the back of the dash mounted heater controls. They do not have a valve in the coolant lines. The heat turned on or off by a vacuum operated door inside the heater box that merely closes and blocks the heat from escaping into the car. If you are having heater problems first make sure both lines running to the firewall feel hot/warm when engine is at temperature. Secondly you will have to find the actuators under dash on the heater box and make sure they are moving if not ck for vacuum.......

- Q: I recently adjusted the valves and put new valve covers on my bug and now I have a leak around the fron corner of one of my valve covers. What happened? What can I do?

- new seals + get rid of the cheapo chrome repros and put OEM covers back on.

- Q: -air pressure of 40 psi only -run on 12v or 250 vac-no need for half open or any of the options i just want it on or off-it will be for a costum use so i dont need any special designs for it any thing will work -it also can be change from gas to water if

- Automatic okorder /

- Q: Hello. I am interested in purchasing a Hydroclean Fill Valve for my toilet. Are these good fill valves? Thanks!

- who cares, a toilet fill valve only costs a few bucks. as long as it opens and closes it's a good valve. if it only lasts for a year then it's a piece of junk and you should try another brand. it's not a major decision

- Q: I am looking for a full valve guitar amp for around ?300.It needs to be loud enough to play with a quietish drum kit.Currently i have looked at an epiphone valve senior in both and combo and cab and head form. i have also looked at some smaller amps such as the vox ac4 but am a bit worried about its small size. any advice would be greatly welcome. many thanks in advance.

- Well I have the Valve Jr. and the AC4. The AC4 is a good sounding amp, but even though it is only 1 watt less, the Valve Jr. is much louder. The AC4 is a great practice amp but not enough to jam with a drummer unless he is pretty quiet and you really crank the amp. Never heard one of the new Valve Sr. models but with all of the goodies they added it should sound really good. I had my Jr. modified but it still doesn't have all the cool stuff the Senior has. I think you would really like the Epiphone and at 20 watts you will be more than loud enough. My 5 watt Jr. will get very loud. All I own are low watt class A valve amps, it's the only way to fly!! The Marshall Class 5 might be worth looking at also.

Send your message to us

DN300 Turbine Type Butterfly Valve with Hand wheel BS Standard

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords