Brushed Gold Anodized One Bar Diamond Aluminum Checker Plate 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

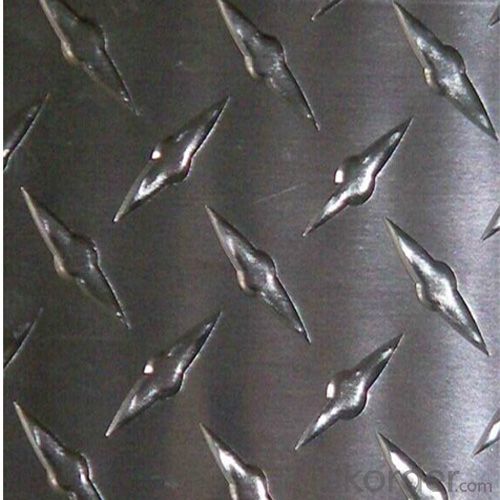

1.Structure of One Bar Diamond Aluminum Checker Plate 3003 Description:

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of One Bar Diamond Aluminum Checker Plate 3003 :

Low density, light in weight

Anti-corrosion

Strong

Malleable

Naturally good looking

Recyclable

3.One Bar Diamond Aluminum Checker Plate 3003 Images:

4. One Bar Diamond Aluminum Checker Plate 3003 Specification:

1. | Item | Aluminum coil/ Aluminum strip,1070 aluminium coil | |

2. | Standard | ATSTM B209, JIS H4000-2006,GB/T3190-2008,GB/T3880-2006, etc. | |

3. | Material | 1000 Series:1050,1060,1080,1100,1435,etc. | |

2000 Series:2011,2014,2017,2024,2A12,2A16,2A06,etc. | |||

3000 Series:3002,3003,3004,3104,3204,3030,3A21,etc. | |||

5000 Series:5005,5025,5040,5052,5056,5083,5A05,etc. | |||

6000 Series:6003,6060,6082,6083,6063,6061,etc. | |||

7000 Series:7003,7005,7050,7075,etc. | |||

4. | Specifications | Thickness | 0.01mm~20mm |

Width | 10mm~2000mm | ||

Length | or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Do 101 aluminum sheets have any specific fire resistance properties?

- No, 101 aluminum sheets do not have any specific fire resistance properties.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- The fourth one.

- Q: How are aluminum sheets different from aluminum plate?

- There are two forms of aluminum metal, namely aluminum sheets and aluminum plates, which primarily differ in terms of thickness. Aluminum sheets are usually thin and flat, with a thickness of less than 6mm. They are commonly utilized in situations where lightweight and flexibility are crucial, such as in the fabrication of aircraft, automobiles, and electronic devices. Conversely, aluminum plates are thicker and heavier than sheets, typically measuring 6mm or more in thickness. Plates are frequently employed in applications that necessitate strength and durability, such as in the assembly of heavy machinery, structural supports, and marine equipment. Despite both sheets and plates being composed of aluminum, their distinctive thicknesses render them suitable for distinct purposes.

- Q: Can aluminum sheets be hydroformed?

- Yes, aluminum sheets can be hydroformed.

- Q: Can the aluminum sheets be used for manufacturing automotive radiators?

- Yes, aluminum sheets can be used for manufacturing automotive radiators. Aluminum is a popular choice for automotive radiators due to its lightweight, excellent heat transfer properties, and corrosion resistance. Aluminum sheets can be easily formed into the required shape and size for radiator construction. Additionally, aluminum radiators offer better cooling efficiency compared to traditional copper radiators. Therefore, using aluminum sheets for manufacturing automotive radiators is a viable and advantageous option.

- Q: What kind of material is 2A12 aluminum sheet?

- Corrosion resistance is poor, but it can be effectively protected by pure aluminum coating. It is easy to crack when welding, but it can be welded or riveted by special process. Widely used in aircraft structures, rivets, truck hubs, propeller components, and many other structures.

- Q: Is it possible to utilize aluminum sheets as materials for car body panels?

- <p>Yes, aluminum sheets can be used for car body panels. They offer several advantages such as lightweight, high strength, and good corrosion resistance. Aluminum is also easily recyclable and can be shaped into complex designs. However, aluminum is less resistant to dents compared to steel, which is a common material for car body panels. Despite this, aluminum's benefits often outweigh its drawbacks, making it a popular choice in the automotive industry, especially for high-performance and electric vehicles where weight reduction is crucial.</p>

- Q: Can aluminum sheets be used for boat building?

- Yes, aluminum sheets can be used for boat building. Aluminum is a popular material choice for boat construction due to its lightweight nature, durability, and resistance to corrosion. Aluminum sheets are commonly used in the construction of small recreational boats, larger yachts, and even commercial vessels. They offer several advantages such as being easy to work with, providing excellent strength-to-weight ratio, and requiring minimal maintenance. Additionally, aluminum boats are known for their superior buoyancy, stability, and fuel efficiency. Overall, aluminum sheets are a suitable and reliable option for boat building.

- Q: Can aluminum sheets be used for food processing equipment?

- Yes, aluminum sheets can be used for food processing equipment. Aluminum is a widely used material in the food industry due to its excellent properties such as corrosion resistance, lightweight, and ability to conduct heat. It is commonly used in the construction of food processing equipment like mixing tanks, conveyors, and food storage containers.

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets depends on various factors, such as the alloy, thickness, and temper of the sheet. However, a general guideline for the minimum bend radius for aluminum sheets is typically around 1 to 1.5 times the material thickness. For example, if you have a 1mm thick aluminum sheet, the minimum bend radius would be around 1 to 1.5mm. It is important to note that this is just a general guideline, and the specific bend radius may vary depending on the specific application and requirements. It is advisable to consult with a professional or reference material specifications for precise bend radius recommendations for a specific aluminum sheet.

Send your message to us

Brushed Gold Anodized One Bar Diamond Aluminum Checker Plate 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords