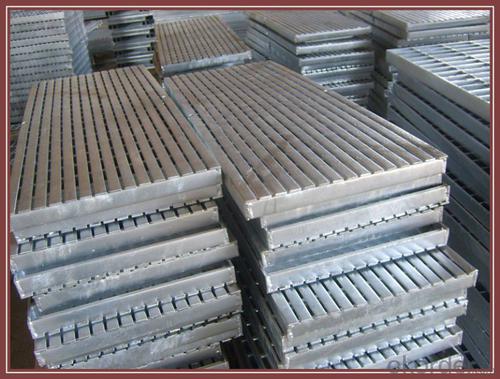

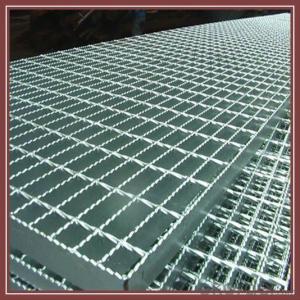

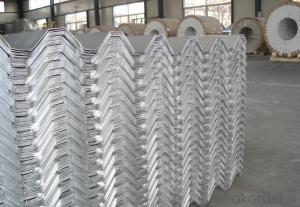

Brushed Aluminum Sheets Houston Aluminum Alloy Grating Staircase/Stair Tread/Stair Step

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Drainage trench cover:

Drainage trench cover is widely used in the urban road, the square, the botanical garden, the wharf, the airport, the parking lot, the road, each kind of industry, the civil project, etc.

2.Main features of Drainage trench cover:

I--Carrying 20 tons of weight

II—Carrying 14 tons of weight

III---carrying 6 tons of weight

IV---carrying 2 tons of weight

V---Carrying pedestrian weight

3.Glass Wool Blanket Images:

4. Drainage Trench Cover Technical Parameters:

These drain cover plate applies to the road cross-sectional and longitudinal drain. The drains width ranging from 200mm to 550mm.

A means the steel grating length

H means the steel grating height

A means the frame length

H means the frame height

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Drainage trench cover is

one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are the aluminum sheets suitable for welding?

- Yes, aluminum sheets are suitable for welding. Aluminum is a popular material for welding due to its lightweight, high strength-to-weight ratio, and corrosion resistance. However, it is important to note that welding aluminum requires specific techniques and considerations compared to other metals. Aluminum has a low melting point and high thermal conductivity, which makes it more challenging to weld compared to steel or other metals. Specialized welding processes, such as Tungsten Inert Gas (TIG) welding or Metal Inert Gas (MIG) welding with a spool gun, are commonly used for aluminum welding. Additionally, proper cleaning and preparation of the aluminum surface, as well as the use of appropriate filler materials, are crucial for achieving strong and durable welds. Overall, with the right equipment, techniques, and expertise, aluminum sheets can be successfully welded to create various structures and components.

- Q: Is it possible to use aluminum sheets in the manufacturing process of solar panels?

- <p>While aluminum sheets can be used in the construction of solar panels, they are not the primary material for making the solar cells themselves. Aluminum is typically used for the frame or backsheet to provide structural support and protection. The actual solar cells are made from materials like silicon, which is capable of converting sunlight into electricity. So, while aluminum plays a role in the assembly of solar panels, it is not used to create the photovoltaic cells that generate power.</p>

- Q: My frame snapped and I want to fix it by welding it back together. In order to do that, I need to know what all is in the aluminum.

- You can NOT weld back an aluminum frame unless you have the facilities to anneal and heat treat the frame again. Rewelding without the post treatments will result in a very soft area around the new weld causing sudden catastrophic failure... this means if you are riding it could fail at any time causing injury or death. EDIT: Wait just a durn minute. The 2100 and 2300 had carbon fiber tubes bonded to aluminum lugs and stays. If your bike failed then you ABSOLUTELY should not try to weld it. The heat from welding (even if you had post treatment facilities) would destroy the bond between the CF and aluminum. Fair warning- cut the frame apart and throw it away.

- Q: Are 101 aluminum sheets resistant to corrosion?

- Yes, 101 aluminum sheets are resistant to corrosion. Aluminum is naturally resistant to corrosion due to its oxide layer that forms on its surface when exposed to oxygen. This oxide layer acts as a protective barrier against corrosion and prevents the metal from deteriorating. Additionally, the 101 aluminum alloy is specifically designed to have enhanced corrosion resistance properties, making it even more resistant to corrosion compared to other aluminum alloys. Therefore, 101 aluminum sheets are a reliable choice when corrosion resistance is a concern.

- Q: Are the aluminum sheets suitable for manufacturing transportation containers?

- Yes, aluminum sheets are suitable for manufacturing transportation containers. Aluminum is lightweight, durable, and corrosion-resistant, making it an ideal material for containers used in transportation. It offers high strength-to-weight ratio and can withstand harsh conditions, making it suitable for various modes of transportation such as trucks, trains, and ships. Additionally, aluminum is recyclable, making it an environmentally friendly choice for container manufacturing.

- Q: How does my world Pocket Monster mod aluminum plate synthesize?

- The first ready aluminum ingot, hammer (wood and iron, iron mat Pocket Monster diamond).1, Pocket Monster put the anvil on the ground;2, holding the hands of ingot right-click on the anvil;3, hand hammer anvil point left to live, etc. the anvil 3 ring or anvil above the lump things deformation 3 times, right click on the anvil can take off the plate

- Q: Are the aluminum sheets suitable for automotive applications?

- Yes, aluminum sheets are suitable for automotive applications. Aluminum is a lightweight material with high strength-to-weight ratio, making it ideal for use in the automotive industry. It offers several advantages such as improved fuel efficiency, better handling, and increased performance. Additionally, aluminum is resistant to corrosion, which is beneficial for automotive applications as it helps increase the lifespan of vehicles. Moreover, aluminum sheets can be easily formed and molded into various shapes, allowing for greater design flexibility in automotive manufacturing. Overall, the use of aluminum sheets in automotive applications has become increasingly popular due to their numerous advantages and positive impact on vehicle performance and sustainability.

- Q: I am doing some exam review and do not know how to do these...Calculate the number of Nitrate ions in 3.99 g or aluminum nitrate.

- ? number of NO3 = 3.99g AlNO3 x(1mol AlNO3/212.996 g AlNO3)x(1mol NO3/1mol AlNO3)x(6.02*10^23 number of NO3/1mol NO3)=11*10^21 number of NO3

- Q: Is it possible to purchase recycled aluminum sheets from a local supplier or manufacturer?

- <p>Yes, you can buy recycled aluminum sheets from local suppliers or manufacturers. Many businesses specialize in recycling and repurposing materials, including aluminum. To find a local supplier, you can search online directories or use business listing services. Additionally, contacting local recycling centers or metalworking businesses may provide leads on available recycled aluminum sheets. It's important to consider the quality, certifications, and environmental impact of the recycled materials when making your purchase.</p>

- Q: This question asks about the various types of adhesives that can be used to bond aluminum sheets together.

- <p>There are several types of adhesives suitable for bonding aluminum sheets together, including epoxy adhesives, which offer strong bonding and resistance to heat and chemicals; acrylic adhesives, known for their flexibility and resistance to UV light; cyanoacrylate adhesives, or super glues, which provide fast bonding but may not be as strong for heavy-duty applications; polyurethane adhesives, which are durable and flexible; and silicone adhesives, which are excellent for high-temperature applications and provide water resistance. Each type has its own advantages and is chosen based on the specific requirements of the bonding task, such as strength, flexibility, temperature resistance, and curing time.</p>

Send your message to us

Brushed Aluminum Sheets Houston Aluminum Alloy Grating Staircase/Stair Tread/Stair Step

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 6000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords