High Strength PVC Coated Polyester/PP Geogrid Geocells Philippines

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

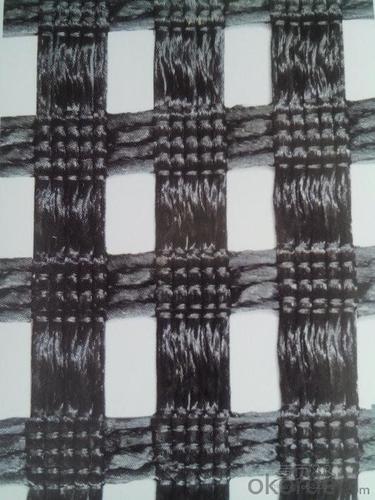

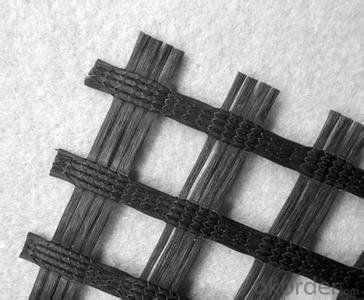

Introduction of Fiberglass Geogrid:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Features:

1.Intensity of vertically and horizontally from 20 KN/M to 150 KN/M

2.Low breaking elongation, not bigger than 3%

3.Suitable for each kind of soil environment

4.For treatment on surface, the rib suppresses the rough pattern, strengthens the grill surface the rough degree, enhances the GSZ steel plastic complex geogrid in the soil body friction factor.

5.It has more superior breadth, up to 2- 6 m, reducing construction joining, enhances the work efficiency.

6.High intensity, low creep and distorting

7.Resistant to erosion, longer life.

8.Easy and convenient to install, short period and low cost- saving. It can save project cost by 10%- 50%.

FAQ:

Q: Can you accept small trial order?

A: Yes, we accept small trial orders at reasonable charge.

Q:May I get one sample for checking out the quality? How much?

A: Yes, we supply sample free of charge, and the freight will be on buyer’s account, which is refundable when order confirmed.

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: What is the effect of moisture on geogrid performance?

- Moisture can have a significant impact on geogrid performance. When geogrids are exposed to moisture, they may experience reduced tensile strength and stiffness, as well as increased elongation and creep deformation. Moisture can also lead to the degradation of geogrid materials, especially if they are not resistant to chemical or biological attack. Additionally, moisture can affect the interaction between geogrids and the surrounding soil, potentially reducing their effectiveness in providing soil reinforcement or confinement. Therefore, it is important to consider and mitigate the effects of moisture when using geogrids in engineering applications.

- Q: Are geogrids suitable for reinforcement of mechanically stabilized aggregate layers?

- Yes, geogrids are suitable for reinforcement of mechanically stabilized aggregate layers. Geogrids are designed to enhance the load-bearing capacity and stability of soil or aggregate layers. They can effectively distribute and transmit load forces, improving the overall performance and longevity of mechanically stabilized aggregate layers.

- Q: Can geogrids be used in reinforcement of rock slopes?

- Yes, geogrids can be used in the reinforcement of rock slopes. Geogrids are commonly used to stabilize and strengthen slopes by improving the stability and increasing the bearing capacity of the soil or rock. They are effective in preventing slope failures and erosion, and can be installed in combination with other methods such as rock bolts or shotcrete to provide additional support and reinforcement to the rock slope.

- Q: How do geogrids compare to other soil reinforcement methods?

- Geogrids are a highly effective soil reinforcement method that offers several advantages over other techniques. Unlike traditional methods like retaining walls or soil nails, geogrids are lightweight and easy to install, making them a cost-effective solution. Geogrids also provide excellent tensile strength and stability, increasing the load-bearing capacity of soil and preventing erosion. Additionally, geogrids are flexible and adaptable, allowing for better distribution of load and accommodating ground movements. Overall, geogrids are a superior choice for soil reinforcement due to their versatility, durability, and cost-efficiency.

- Q: How do geogrids improve the bearing capacity of foundations?

- Geogrids improve the bearing capacity of foundations by increasing soil stability and reinforcement. They act as a mesh or lattice-like structure that is placed within the soil, distributing the load more evenly and preventing soil from shifting or settling. This helps to reduce settlement and improve the overall strength and stability of the foundation.

- Q: How do geogrids improve the performance of geotextile erosion control blankets?

- Geogrids improve the performance of geotextile erosion control blankets by providing additional reinforcement and stability to the blanket. They help distribute loads more evenly, prevent soil erosion, and enhance the overall strength and durability of the erosion control system.

- Q: How do geogrids enhance the load-bearing capacity of pavements?

- Geogrids enhance the load-bearing capacity of pavements by providing reinforcement and stabilization. They are installed within the pavement structure to distribute and limit the movement of loads, effectively increasing the pavement's strength and durability. Geogrids also help to reduce strain and prevent cracking, improving the overall performance and lifespan of the pavement.

- Q: How to read geogrid grilleBe careful not to copy the dictionary. I want to know why he read it hereI look at the dictionary said: the gate of zhBlock made of bamboo, iron bars, etc.. barsIs it because geogrid can also be seen as a strip of things, so read Zha

- Normal should read Zha, but because of the dialect or engineering terminology habits, read Shan, habit, this is just a personal idea.

- Q: What are the differences between geogrids and geotubes?

- Geogrids and geotubes are both geosynthetic materials used in civil engineering and environmental applications, but they have distinct differences. Geogrids are typically made of polymer materials and are designed to provide soil reinforcement and stabilization. They have a grid-like structure with open spaces and are used to improve the strength and bearing capacity of soils. Geogrids are commonly used in road construction, retaining walls, and slope stabilization projects. On the other hand, geotubes are large, tubular containers made from high-strength woven or non-woven geotextile fabrics. They are used for shoreline protection, coastal erosion control, and dewatering applications. Geotubes are filled with sediment, sludge, or other materials and then dewatered, allowing water to escape while retaining the solid contents. They are often used in coastal engineering projects to create or restore beaches, control erosion, and contain contaminants. In summary, while geogrids are used for soil reinforcement and stabilization, geotubes are used for dewatering and containment purposes in coastal and environmental applications.

- Q: Can geogrids be used in reinforcement of concrete pavements?

- Yes, geogrids can be used in the reinforcement of concrete pavements. Geogrids are commonly used to enhance the structural integrity and performance of concrete pavements by providing additional tensile strength and distributing loads more effectively. They can help prevent cracking and increase the overall durability of the pavement.

Send your message to us

High Strength PVC Coated Polyester/PP Geogrid Geocells Philippines

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords