Black EPDM Waterproof Rubber Sheets High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

Product Instruction:

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

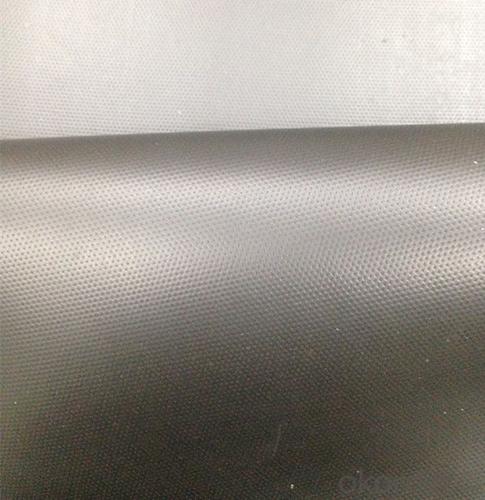

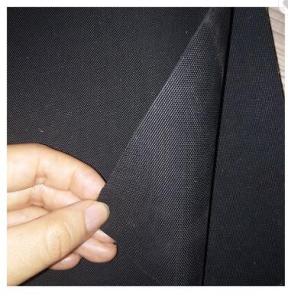

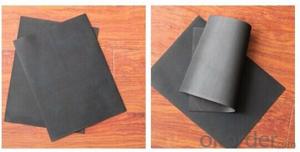

Photos:

- Q: What are the common mistakes to avoid when installing a waterproofing membrane?

- To ensure the effectiveness and longevity of a waterproofing membrane, it is crucial to steer clear of certain common mistakes. These mistakes can include: 1. Insufficient surface preparation: One of the most prevalent errors is neglecting to adequately prepare the surface before membrane installation. This may involve not thoroughly cleaning the surface, leaving cracks or holes unfilled, or failing to remove loose debris. Inadequate surface preparation can compromise the membrane's adhesion and result in leaks. 2. Improper selection of membrane: Selecting the wrong type of waterproofing membrane can prove to be a costly blunder. Different membranes are designed for specific applications and environmental conditions. It is essential to choose a membrane that is suitable for the specific project requirements in order to ensure its effectiveness and durability. 3. Insufficient membrane overlap: Properly overlapping the membrane is crucial in creating a continuous barrier against water infiltration. Insufficient overlap can result in water seepage and jeopardize the integrity of the waterproofing system. It is important to adhere to the manufacturer's instructions regarding the recommended overlap width and ensure proper adhesion between the overlapped sections. 4. Incorrect membrane installation: Improper installation techniques can also lead to issues with the waterproofing membrane. This can include uneven application of the membrane or using incorrect installation tools. It is imperative to adhere to the manufacturer's guidelines and recommendations for installation to guarantee a proper and effective waterproofing system. 5. Neglecting proper drainage: Adequate drainage should always accompany waterproofing membranes. Failure to install proper drainage can lead to water pooling on the surface, which can cause membrane degradation and potential leaks. It is important to consider the slope and design of the drainage system to ensure efficient water removal. 6. Lack of regular inspection and maintenance: Once the waterproofing membrane is installed, regular inspections and maintenance are essential. Neglecting these can result in unnoticed issues such as damage or deterioration, which can compromise the waterproofing system. Regular inspections and timely repairs or maintenance can help extend the life of the membrane and prevent costly repairs in the future. By avoiding these common mistakes during the installation process and ensuring proper maintenance, you can enhance the effectiveness and longevity of your waterproofing membrane, providing reliable protection against water infiltration.

- Q: Are waterproofing membranes resistant to ammonia?

- In general, waterproofing membranes can resist ammonia. Ammonia is a chemical compound commonly found in cleaning agents and fertilizers, and it can corrode certain materials. However, waterproofing membranes are specifically designed to withstand various chemicals and environmental conditions, including ammonia exposure. These membranes are typically made from materials like PVC, EPDM, or modified bitumen, which have excellent chemical resistance properties. Therefore, when installed correctly, waterproofing membranes should act as a barrier against ammonia, preventing it from penetrating underlying structures. It's important to note that the resistance of a waterproofing membrane to ammonia may vary depending on factors such as the type and quality of the membrane, as well as the concentration and duration of exposure. Thus, it is always advisable to consult the manufacturer's guidelines and conduct compatibility testing before using any waterproofing membrane in an environment with ammonia.

- Q: Can a waterproofing membrane be used on storage tanks?

- Yes, a waterproofing membrane can be used on storage tanks to prevent water leakage and protect the tank from corrosion.

- Q: SBS waterproofing membrane how to sample

- Chlorinated polyethylene - rubber blends waterproofing membrane: the same specifications are not more than 250 volumes for a group, the appearance of qualified in each batch of 1 volume Asphalt composite tire flexible waterproofing membrane: the same specifications are not more than 1000m2 for a group, each batch of 1 volume

- Q: Can a waterproofing membrane be used on below-grade foundations?

- Yes, a waterproofing membrane can be used on below-grade foundations. Waterproofing membranes are commonly used to prevent water infiltration and protect the foundation from moisture damage in below-grade applications.

- Q: Does a waterproofing membrane have any impact on the appearance of a surface?

- Yes, a waterproofing membrane can have an impact on the appearance of a surface. Depending on the type and application method of the membrane, it may add a layer of protection that alters the texture, sheen, or color of the surface. Additionally, some membranes may be visible or create a slightly raised or textured effect on the surface. However, there are also transparent or thin membranes available that have minimal impact on the appearance of the surface.

- Q: Can a waterproofing membrane be used for plant rooms?

- Yes, a waterproofing membrane can be used for plant rooms. Waterproofing membranes are commonly used in various applications, including plant rooms, to prevent water penetration and protect the structure from moisture damage. These membranes help maintain a dry and controlled environment, which is essential for the proper functioning and longevity of equipment in plant rooms.

- Q: Can a waterproofing membrane be used on zinc surfaces?

- Certainly! Zinc surfaces can indeed benefit from the application of a waterproofing membrane. Zinc is widely used for its durability and resistance to corrosion, making it a popular choice for various purposes such as roofing and cladding. By adding a waterproofing membrane to zinc surfaces, an extra layer of protection against water intrusion and moisture damage can be achieved. This not only helps prevent leaks, but also extends the lifespan of the zinc surface and preserves its overall integrity. However, it is crucial to ensure that the chosen waterproofing membrane is compatible with zinc and specifically designed for such applications. To determine the most suitable waterproofing solution for zinc surfaces, it is advisable to seek professional advice or consult with the manufacturer.

- Q: Can a waterproofing membrane be used on gypsum block surfaces?

- Yes, a waterproofing membrane can be used on gypsum block surfaces. Gypsum blocks are porous and can be prone to moisture infiltration, so applying a waterproofing membrane can help prevent water damage and moisture-related issues.

- Q: Can a waterproofing membrane be installed under tile or other flooring materials?

- Installing a waterproofing membrane is possible under various flooring materials, including tile. Typically used in areas prone to moisture, like bathrooms, kitchens, and basements, these membranes serve as a protective barrier. Their purpose is to prevent water from seeping through the floor and causing harm to the underlying structure. Usually, they are applied directly onto the substrate before the tile or flooring material is installed. This guarantees that any water or moisture that manages to infiltrate the flooring is redirected and prevented from reaching the subfloor. By utilizing a waterproofing membrane, you can safeguard your floors, extend their lifespan, and create a dry, moisture-free environment.

Send your message to us

Black EPDM Waterproof Rubber Sheets High Tensile Strength

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3500 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords