Black EPDM Rubber Flat Roofing Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

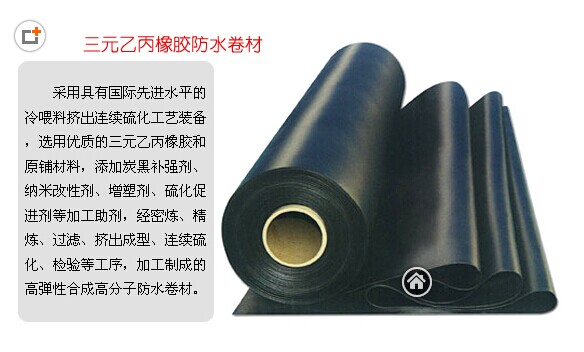

EPDM Waterproof Membrane

Specifications

ASTM Standard D-7465,D-4367

thickness:1.2mm,width:4m,length:20m

eco-friendly

widely exported to Australia, UK,Argentina etc.

1.2mmEPDM rubber flat roofing material.

EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material. EPDM waterproof membrane is made from ternary ethylene-propylene rubber, which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane production adopts the world-advanced equipment of cold feeding extrusion and continuous vulcanization technology.

Features

Excellent weatherability, durability and size stability

Good adaptability to high and low temperature, UV resistant and anti-corrosion

High tensilestrength and good elongation, accommodating substrate movement

Easy installation, environment friengly

Good rooting penetration resistance

Service life up to 50 years

Applications

Subways, tunnels, roofs, basement

Industrial and civil building waterproofing, like water reservior, bridge, dam, etc.

Geosynthetic liner for swimming pool, channels, irrigation system

Especially suitale for projects with high requirements in durability, anti-corrosion and deformation

Application Method:

1. Make sure the roof deck smooth,clean and dry(Moisture<9%),then apply the surface of roof deck homogeneously with a kind bitumen paint till dry to start application.

2. There are two methods in application:

One way is by heating and melting method---Heat the polyethylene film of the membrane and roof deck surface by heating and melting method to be nearly melted(not flowing),then install the membrane fully bonded to the roof deck with overlaps of 5-10cm.

The other way is by cold adhesive method---Pour the cold adhesive homogeneously on the roof deck then roll the membrane to install it to be fully sticked to roof deck.

By heating and melting method and by cold adhesive can be used in alternation in application as requested.

3. After application,a full serious inspection is required to make sure no air bubble,no fold,no falling away etc to guarantee the waterproof life.

Attentions for Construction:

Construction shall not be carried out in rain, snow or over 5 degree wind weather; There shall be sufficient safety protective facilities in construction site, place firefighting devices according to stipulations

1. Clean the substrate using broom or high pressure dusty cleaner

2. Apply primer

3. Heat the membrane bottom using a high temperature flame gun

4. Push forward while the primer and membrane oil melted

5. Use a roller to push hard the membrane surface to ensure it stick firmly

Some photos:

- Q: Are waterproofing membranes resistant to frost damage?

- Yes, waterproofing membranes are designed to be resistant to frost damage. They are typically made from durable materials that can withstand freezing temperatures without cracking or deteriorating.

- Q: Can a waterproofing membrane be used in areas with extreme temperatures?

- Yes, a waterproofing membrane can be used in areas with extreme temperatures. Waterproofing membranes are designed to withstand a wide range of temperatures and are often used in both hot and cold climates. They are engineered to be flexible and durable, allowing them to effectively protect against water intrusion and withstand temperature fluctuations without losing their effectiveness.

- Q: Can a waterproofing membrane be used on tunnels with historical significance?

- Yes, a waterproofing membrane can be used on tunnels with historical significance. The membrane can help protect the tunnel from water damage and prevent further deterioration, ensuring the preservation of its historical significance.

- Q: What is sbs, app modified asphalt waterproofing membrane

- Compared to the use of SBS waterproofing membrane to use a larger range. But each has its own advantages and disadvantages, according to the local environment and the actual situation of the building in combination with the characteristics of two kinds of coil to choose materials. You have to compare the next, I can only tell you SBS waterproofing membrane prices than APP waterproofing membrane high.

- Q: Can a waterproofing membrane be applied to horizontal surfaces?

- Yes, a waterproofing membrane can be applied to horizontal surfaces. In fact, it is commonly used to protect and waterproof horizontal surfaces such as roofs, decks, balconies, and other flat areas. The membrane acts as a barrier, preventing water from penetrating the surface and causing damage. It is typically made of a flexible material, such as rubber or modified bitumen, which can easily conform to the contours of the horizontal surface. Additionally, the membrane is designed to withstand foot traffic and other loads, ensuring long-lasting protection. Overall, applying a waterproofing membrane to horizontal surfaces is an effective way to prevent water damage and extend the lifespan of the surface.

- Q: Can a waterproofing membrane be used in areas with chemical exposure, such as industrial settings?

- Yes, a waterproofing membrane can be used in areas with chemical exposure, such as industrial settings. Waterproofing membranes are designed to provide protection against water penetration and can also offer resistance to certain chemicals. However, the specific type of waterproofing membrane and its chemical resistance properties should be carefully selected to ensure compatibility with the specific chemicals present in the industrial setting. Consulting with a professional or manufacturer is advised to ensure proper selection and installation of a waterproofing membrane in such environments.

- Q: Can waterproofing membranes be used on concrete countertops?

- Concrete countertops can indeed benefit from the application of waterproofing membranes. These membranes are specially crafted to thwart the infiltration of water and can be utilized on diverse surfaces, including concrete. By opting for a waterproofing membrane on a concrete countertop, one can effectively safeguard it against water harm, staining, and possible structural concerns. Furthermore, these membranes can augment the countertop's resilience and lifespan by averting moisture-induced problems, such as cracking or warping. It is imperative to verify that the selected waterproofing membrane is concrete-compatible and appropriate for countertop use.

- Q: Can a waterproofing membrane be used for outdoor applications?

- Yes, a waterproofing membrane can be used for outdoor applications. Waterproofing membranes are specifically designed to provide protection against water and moisture infiltration, making them ideal for outdoor use where exposure to rain, snow, and other weather elements is a concern. These membranes are commonly used in various outdoor applications such as roofs, balconies, decks, and foundations to prevent water damage and ensure long-term durability. They are highly effective in creating a barrier that keeps water out while allowing the structure to breathe, preventing the accumulation of moisture and potential issues like mold and rot. Overall, using a waterproofing membrane for outdoor applications is a smart choice to enhance the longevity and performance of the structure.

- Q: Can a waterproofing membrane protect against mold or mildew growth?

- Yes, a waterproofing membrane can help protect against mold or mildew growth. Mold and mildew thrive in damp and moist environments, and a waterproofing membrane creates a barrier that prevents water from seeping into the building structure. By keeping the area dry, it greatly reduces the chances of mold or mildew growth. Additionally, waterproofing membranes often have anti-microbial properties that inhibit the growth of mold and mildew even further. However, it's important to note that while a waterproofing membrane can provide significant protection against mold and mildew, it is not a foolproof solution. Proper ventilation and regular maintenance are also essential to prevent these issues.

- Q: Is a waterproofing membrane resistant to saltwater or other corrosive substances?

- Yes, a waterproofing membrane is typically resistant to saltwater and other corrosive substances. The membrane is designed to provide a protective barrier against moisture and chemicals, ensuring durability and preventing damage caused by corrosive elements.

Send your message to us

Black EPDM Rubber Flat Roofing Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords