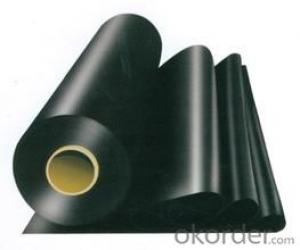

EPDM Rubber Waterproof liner High Tensile Strength Good Elongation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3200 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

Product Instruction:

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

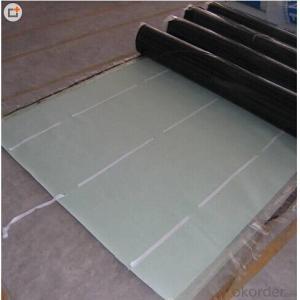

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

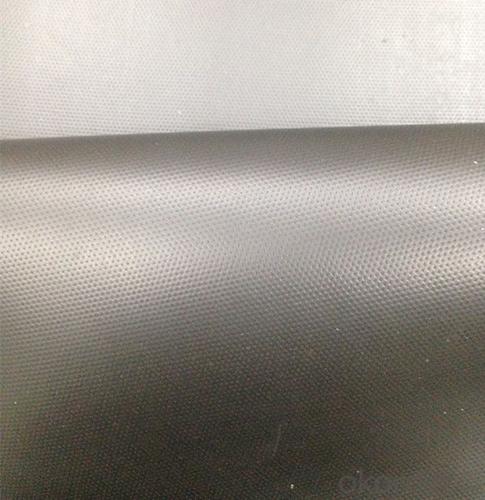

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

Photos:

- Q: Can a waterproofing membrane be used in bridge decks or roadways?

- Yes, bridge decks and roadways can benefit from the use of a waterproofing membrane. This protective layer prevents water infiltration and increases the lifespan of the structure. Given the harsh weather conditions and heavy traffic that bridge decks and roadways face, a waterproofing membrane is essential. Water penetration can cause damage to bridge decks and roadways, including corrosion of steel reinforcements and deterioration of concrete. By applying a waterproofing membrane, a barrier is created to prevent water from seeping into the structural elements. This reduces the risk of corrosion and extends the durability of the bridge or roadway. Additionally, a waterproofing membrane can help prevent the formation of cracks and potholes, which are often caused by the freeze-thaw cycle and water penetration. By keeping the surface of the bridge deck or roadway dry, the membrane maintains its structural integrity and avoids costly repairs or premature replacement. It is important to consider factors such as material selection, installation techniques, and maintenance when using a waterproofing membrane in bridge decks or roadways. The chosen membrane should be compatible with the construction materials, and the installation process must be done correctly to ensure a watertight seal. Regular maintenance and inspections should also be done to identify any issues or damage to the membrane. This allows for timely repairs and ensures its effectiveness over time. Overall, using a waterproofing membrane in bridge decks or roadways is an efficient solution to protect against water damage and extend the lifespan of these critical infrastructure elements.

- Q: Can a waterproofing membrane be used on precast concrete surfaces?

- Yes, a waterproofing membrane can be used on precast concrete surfaces. Precast concrete surfaces are commonly used in construction for various applications such as walls, floors, and roofs. These surfaces are prone to water penetration, which can cause damage and deterioration over time. To prevent this, a waterproofing membrane can be applied to the precast concrete surface. A waterproofing membrane is a thin layer of material that is designed to prevent the passage of water. It is typically made of materials such as bitumen, rubber, or PVC. The membrane is applied to the surface of the precast concrete and acts as a barrier, preventing water from seeping into the concrete. There are several benefits to using a waterproofing membrane on precast concrete surfaces. Firstly, it helps to extend the lifespan of the precast concrete by protecting it from water damage. Water can cause the concrete to crack, corrode reinforcement, and lead to the growth of mold and mildew. By applying a waterproofing membrane, these issues can be minimized or prevented altogether. Secondly, a waterproofing membrane can improve the overall performance of the precast concrete. By preventing water penetration, the membrane helps to maintain the structural integrity of the concrete. It also helps to maintain a dry and comfortable environment inside buildings by preventing water leakage. Lastly, a waterproofing membrane can provide additional protection against other elements such as chemicals and UV rays. Some membranes are designed to resist chemical exposure, which can be beneficial in industrial or commercial settings. Additionally, certain membranes have UV-resistant properties, which can help to prevent damage caused by prolonged exposure to sunlight. In conclusion, a waterproofing membrane can be used effectively on precast concrete surfaces to prevent water penetration and protect the concrete from damage. It is a cost-effective and efficient solution to ensure the durability and longevity of precast concrete structures.

- Q: Can a waterproofing membrane be used for a commercial building?

- Yes, a waterproofing membrane can be used for a commercial building. Waterproofing membranes are commonly used in commercial buildings to protect the structure and prevent water damage. They provide an effective barrier against moisture and can be applied to various surfaces such as roofs, basements, and foundations. This helps to maintain the integrity and longevity of the building, preventing leaks and potential structural issues.

- Q: Can a waterproofing membrane be used for tunnels and subway stations?

- Yes, a waterproofing membrane can be used for tunnels and subway stations. The membrane acts as a barrier against water infiltration and helps protect the structure from water damage. It is commonly used in underground construction projects to ensure the longevity and safety of tunnels and subway stations.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oil spills?

- Yes, a waterproofing membrane is typically resistant to hydrocarbons or oil spills. Waterproofing membranes are designed to create a barrier that prevents water penetration and moisture damage to the underlying surfaces. These membranes are often made from materials such as modified bitumen, polyurethane, or PVC, which have excellent resistance to various chemicals, including hydrocarbons and oil. This resistance ensures that the membrane remains intact and effective even when exposed to oil spills or hydrocarbon-based substances. However, it is essential to note that the specific resistance may vary depending on the type and quality of the waterproofing membrane used. Therefore, it is crucial to select a membrane that is specifically engineered to withstand the intended environment and potential chemical exposures.

- Q: Can a waterproofing membrane be applied to uneven surfaces?

- Yes, a waterproofing membrane can be applied to uneven surfaces. However, the level of success and effectiveness may vary depending on the severity of the unevenness. It is important to properly prepare the surface by removing any loose debris, filling in large gaps or holes, and smoothening out any high points or ridges. There are also certain types of waterproofing membranes that are more flexible and can conform to uneven surfaces better than others. It is recommended to consult with a professional waterproofing contractor who can assess the condition of the surface and recommend the most suitable waterproofing membrane for the specific unevenness.

- Q: Can a waterproofing membrane be used in conjunction with green building practices?

- Yes, a waterproofing membrane can definitely be used in conjunction with green building practices. In fact, incorporating a waterproofing membrane into the construction of a green building can help enhance its overall sustainability and efficiency. One of the key principles of green building practices is to maximize energy efficiency and reduce the environmental impact of a building. By installing a waterproofing membrane, the building's envelope can be protected from moisture intrusion, preventing water damage and potential mold growth. This, in turn, helps maintain the structural integrity of the building, reducing the need for repairs and replacements, which can be resource-intensive and generate waste. Additionally, a waterproofing membrane can contribute to better indoor air quality. By preventing water infiltration, it helps create a dry and healthy living or working environment, minimizing the risk of respiratory issues and other health problems associated with dampness. Furthermore, a waterproofing membrane can improve the energy efficiency of a building. By preventing water from seeping into the walls or foundation, it reduces the potential for heat loss through moisture evaporation, thus reducing the energy needed for heating and cooling. This can lead to reduced energy consumption and lower carbon emissions, aligning with the goals of green building practices. It is important, however, to choose a waterproofing membrane that is environmentally friendly and meets green building standards. Look for membranes that are made from recycled or sustainable materials and have low VOC (volatile organic compound) content. Additionally, consider selecting a membrane that is designed for durability and longevity, as this can further reduce the environmental impact by minimizing the need for replacement over time. In conclusion, a waterproofing membrane can be a valuable addition to any green building project. It helps protect the building envelope, improves indoor air quality, and enhances energy efficiency. By selecting an environmentally friendly membrane, the overall sustainability of the building can be further improved.

- Q: Can a waterproofing membrane be used for airport runways?

- Airport runways, when faced with heavy aircraft traffic, weather conditions, and potential fuel spills, undergo significant wear and tear. To combat this, a waterproofing membrane can be utilized. This membrane acts as a protective shield, preventing water infiltration and subsequent runway deterioration. Moreover, it acts as a barrier against fuel, oil, and other chemicals that can weaken the runway structure. By reducing the impact of freeze-thaw cycles and obstructing the formation of cracks and potholes, a waterproofing membrane effectively prolongs the runway's lifespan. Ultimately, incorporating a waterproofing membrane enhances the durability and safety of airport runways, ensuring seamless operations and minimal maintenance expenses.

- Q: Can a waterproofing membrane be used for a garden pond liner?

- Yes, a waterproofing membrane can be used for a garden pond liner. A waterproofing membrane is designed to prevent water from penetrating through it, making it an ideal choice for creating a watertight barrier in a garden pond. It can effectively prevent leaks and ensure that the water remains contained within the pond. Additionally, waterproofing membranes are typically durable and resistant to UV rays, chemicals, and punctures, which are all important factors to consider when selecting a material for a pond liner. However, it is crucial to ensure that the waterproofing membrane chosen is specifically designed for use in ponds and is safe for aquatic life.

- Q: Is a waterproofing membrane resistant to saltwater or salt damage?

- Yes, a waterproofing membrane is resistant to saltwater or salt damage. Its composition and design make it highly durable and capable of withstanding the corrosive effects of saltwater, ensuring long-term protection against leaks and seepage.

Send your message to us

EPDM Rubber Waterproof liner High Tensile Strength Good Elongation

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3200 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords