Black Annealed Iron Wire with Soft Quality&Hard Quality Widely Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Black Annealed Iron Wire Description:

Black Annealed Iron Wire comes in the form of coil wire or cut wire. Going through the processing of oxygen free annealing, the iron wire becomes soft and more flexible. It is supplied in reel, coil or cut into certain sizes or in U shape.

Black Annealed Iron Wireis mainly used as industrial wire, construction wire, industrial tie wire and construction tie wire, etc. Black annealed iron wire is also used in redrawing wire, weaving mesh, communication equipments, handcrafts, artwork, etc. It is also widely used as tie wire or binding wire in construction, etc.Black Annealed Wire is mainly processed into coil wire, spool wire or big package wire. Annealed wire is used as tie wire or baling wire in building, parks and daily binding. Besides, black annealed wire is mainly used as industrial wire, construction wire, industrial bale tie wire and constructional tie wire, etc.

2.Main Features of Black Annealed Iron Wire:

Black and soft, high tensile strength, can be used as tie wire in construction, etc.

3. Black Annealed Iron Wire Images

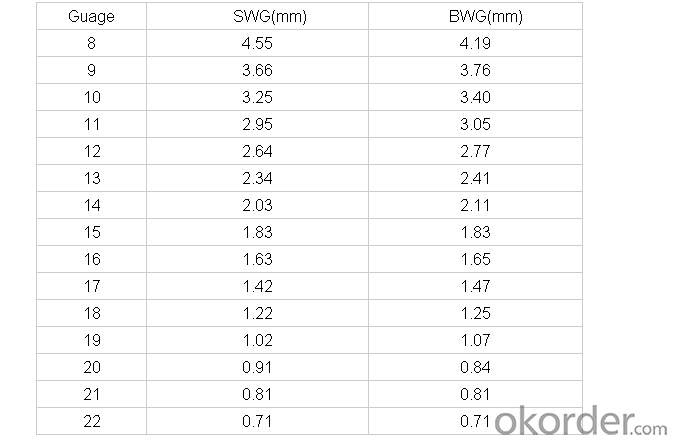

4.Black Annealed Iron Wire Specification

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your products?

We are focus on steel wire producing for more than ten years, supplying wire products like Black Annealed Iron Wire, Galvanized wire, barbed wire,Plain Wire, Loose TIe Wire, etc.We have big production line and offer high quality steel wire, the quality is guaranteed.

②what is the advantage of our Black Annealed Iron Wire?

1. Durable service life and competitive price.

2. High quality and low price.

3. With good anti-corrosive

4. Beautiful, strong and not expensive.

③How long can we receive the product after purchase?

After we receive your payment,Usually It will need about 20 days to prepare the goods. That depends on your quantity.

- Q: alright, 5 speakers with 4ohm svc, what would my wiring options be?

- With 5 speakers there won't be a symmetral wiring pattern for even power distribution. With 4 it would be 2 pair in parallel with both sets in series for a 4 ohm final load or all 4 in parallel for a 1 ohm final load.

- Q: I am changing an outside light with a inside wall switch there is 2 cables going to the outside box. ( 3 wires -white w/red line wire and black wire and green ground wire ) other cable 3 wires is white wire and black wire and green ground wire.On the inside switch is 3 wires white wire a black wire a green ground wire.for some reason it is not working, can any one tell me how to wire and or test for power. thank you

- IF switch and bulb are good, have you tested the light socket? Black is the HOT lead. Power (hot) goes from box, to switch, to light, to neutral (power.) THIS puts the switch in the HOT lead. Green (ground) connects to ALL points.

- Q: does it matter what gauge speaker wire to use when hooking up a powered subwoofer?

- A Powered subwoofer does not use speaker wire - it usually uses a RCA cable. EDIT: Ok - some older subwoofers only have speaker inputs and speaker outputs. You run speaker wire from the Left/Right speaker outputs to the sub, it strips off the sounds it wants to produce, and it passes the other sounds onto the other speakers. I suggest some good oxygen free 12 ga wire. There is a roll off effect with higher frequency sounds and long runs of speaker wire. It usually does not matter for a Home Theater system, but you can hear it with a high-end music system. Thicker wire reduces the effect. Since with a sub you would be running wires to the sub, then back to the L/R speakers, you could be using 15-30 ft of wire. Get a spool of good 12 ga from a speaker building site or get some of the Carol 12 speaker wire from Home Depot.

- Q: Just moved into a new house and the basement is already wired for surround sound. The ends are two wires one silver one gold/brass wrapped together with plastic. Looks like they were cut at the ends. How difficult would it be to wore the speakers myself?

- If the wire you are referring to is standard speaker wire, then you wire it to your speakers, at one end, and to your receiver, at the other end, the same way that you normally wire up speakers. In other words, always connect the same colour of wire to each positive connection, and the other colour to all of the negative connections.

- Q: I have a set of pilot wi-200 strobe lights and they have three wires and i want to hook them up to a optx headlight strobe control module the wires are gray white and black can you tell me where to hook them

- I wouldn't try it. The gray, white, and black wires are the high voltage strobe wires. The control module changes the patterns before the voltage is increased. There is nothing you can do here.

- Q: how to connect the wiring from car stereo to amplifier

- The consistent potential twine is nearly a small direct line from the battery, as in it is many times warm, yet once you have been placing it to the useful of the upload-ons it could have in basic terms been becoming a circuit. it is to no longer say which you probably did no longer short out the wiring some incorrect way and that i'm unsure what the twine grew to become into which you genuinely touched with the consistent, yet it is many times run from the useful part as a relentless, till you have a grounded useful electric equipment on your motor vehicle. you does not in an '89 Escort till you probably did that your self. Wiring could be with any luck fused, even regardless of the indisputable fact that i do no longer understand how some distance back the fusing may well be, no count number if or no longer this is each and every of the previously to the fuse field or a separate fuse closer to the wiring.

- Q: my rabbit is chewing wires and in one area in my room there are like 300 wires i was just wondering if i can spray something on the wires cause i thought i saw something that said that please help!!!!

- I agree with Astrid. My rabbit does not chew on wires, but she insist on grabbing the bars of her cage at 4am, and shaking the heck out of them, so before I go to bed I put bitter apple on the bars.

- Q: hey could anyone tell me from the stock am radio in my nissan 720 what wires are the constant (memory) power and the accessory (ignition) wire so i can attach these to my new radio

- The best way to find out is with a voltmeter, or a 12V lamp. Connect one end to ground (-), and the other to each wire. With power indicated while the ignition is off, you've fount the memory keep-alive line. With power only while the ignition is on, you've found the accessory line.

- Q: How do I wire MULTIPLE ones? I checked many sites and yes, I do get schematics, I've seen a billion schematics, but now I don't know how to actually put it together.My big question is, can I just solder two wires running from my 5V + terminal like that? Would there be problems?So if I have a 5V battery.

- You can do this a number of ways. All of the postive terminals must be connected in some way and all of the commons must be connected in some way. This doesn't mean you have to connect each positive to every other postive, and likewise for the common. You have a few options: You can solder two wires to the positive terminal of the battery and run one wire to each load (device). You can solder one wire to the positive terminal of the battery, run this wire to the first load (device), solder another wire to the first load (device), connect this wire to the second load(device). You can solder one wire to the positive terminal to the battery, run this wire to the second load, solder an additional wire to the second load, and run the second wire to the first load. In industry, power wires are typically jumped from one device to the next to delivery power to each device that needs it. Basically, your power needs to go to each one. How you connect them is up to you.

- Q: electroluminescent wire picture?

- what do you want to know about electroluminescent wire

Send your message to us

Black Annealed Iron Wire with Soft Quality&Hard Quality Widely Use

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords