Bearing Steel Rod 52100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Steel Grade: | Standard: | Dimensions: | |||

| Place of Origin: | Brand Name: | Model Number: | |||

| Technique: | Application: | Alloy Or Not: | |||

| Special Use: | Type: | Grade: | |||

| Surface treatment: | Delivery condition: | Main products: | |||

| Trade term: |

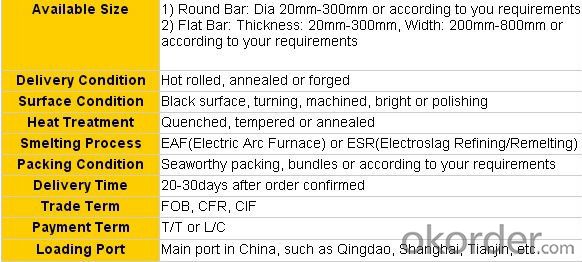

Packaging & Delivery

| Packaging Detail: | GCr15 bearing steel: Seaworthy package or according to buyers' requirement |

| Delivery Detail: | 30days |

Specifications

Bearing Steel Rod 52100

1)Competitive price

2)High chromium bearing steel

3)ISO 9001:2008 and SGS

Bearing Steel Rod 52100

Steel Material: ASTM 52100,JIS SUJ2,BS100Cr6, GB GCr15 high-carbon chromium bearing steel

Similar or Equivalent Grades

GB | AISI | ISO | JIS |

GCr15 | 52100 | 100Cr6 | SUJ2 |

Chemical composition

Mechanical Property

Delivery State | |

Brinell Hardness HBS | Impression Diameter /mm |

179-207 | 4.2-4.5 |

Characteristics

1) Good hardability and high toughness

2) Long fatigue life

3) Medium cold processing plasticity

4) Certain machinability

5) Poor weldability

Application

1) Steel ball, roller and collar of large machinery bearing

2) High-hardness and high contact fatigue strength machinery parts with heavy load, such as axis of rotation, blade, stator pump, profiling, sleeve, mandril, etc.

Description Details

- Q: What are the properties of nitrogen alloyed steel?

- Nitrogen alloyed steel typically exhibits improved strength, hardness, and corrosion resistance compared to regular carbon steel. It also has excellent wear resistance and may have enhanced toughness. Additionally, nitrogen alloying can improve the steel's ability to retain its properties at high temperatures, making it suitable for applications in challenging environments.

- Q: How does special steel contribute to the manufacturing of oil and gas equipment?

- Special steel plays a vital role in the manufacturing of oil and gas equipment by offering exceptional strength, corrosion resistance, and high-temperature stability. This type of steel is specifically designed to withstand the harsh and challenging conditions encountered in the oil and gas industry, such as extreme temperatures, pressure, and corrosive environments. It is used to construct various components of equipment like pipes, valves, fittings, drilling tools, and offshore platforms. Special steel's superior properties ensure the reliability, durability, and safety of oil and gas equipment, enabling efficient operations in this critical sector.

- Q: What are the advantages of using special steel in various industries?

- Special steel offers several advantages in various industries. Firstly, it has superior strength and durability, making it ideal for applications that require high resistance to wear, impact, and corrosion. This enables the production of longer-lasting and more reliable components, reducing maintenance and replacement costs. Additionally, special steel can be tailored to meet specific requirements, such as temperature resistance or magnetic properties, allowing for customization in different industries. Furthermore, its excellent machinability and weldability make it easier to work with and shape into complex forms, enhancing design flexibility. Finally, special steel's ability to withstand extreme conditions and harsh environments makes it ideal for industries like aerospace, automotive, construction, energy, and manufacturing. Overall, the use of special steel enhances performance, efficiency, and longevity in various industrial applications.

- Q: What are the specific requirements for special steel used in the automotive piston industry?

- In order to ensure high performance, durability, and efficiency of pistons in the automotive piston industry, specific requirements for the special steel used have been established. These requirements encompass the following: 1. High tensile strength and hardness are essential for the special steel used in automotive pistons to withstand the extreme pressures and temperatures generated during combustion. 2. The steel must exhibit exceptional heat resistance properties to endure the intense heat produced by the combustion process without distorting or losing strength. 3. Given the constant friction and wear that pistons endure against the cylinder walls, the special steel used must possess good wear resistance to minimize wear and tear and extend the lifespan of the piston. 4. To ensure a secure seal between the piston and cylinder walls, the steel should have a low coefficient of thermal expansion, preventing excessive expansion and contraction during temperature fluctuations. 5. Since pistons are exposed to various corrosive elements, such as combustion by-products and engine oil, the special steel used in their manufacturing must possess good corrosion resistance to prevent premature deterioration and failure. 6. The steel should exhibit excellent fatigue resistance to withstand the repetitive stress cycles experienced by the piston during engine operation. 7. Special steel used in pistons should be easily machinable, allowing for precise dimensions and tolerances necessary for optimal performance. 8. While meeting the aforementioned requirements, special steel used in the automotive piston industry should also be cost-effective to ensure profitability for manufacturers. By meeting these specific requirements, the special steel used in the automotive piston industry contributes to the overall performance, reliability, and longevity of the piston. Consequently, this enhances the efficiency and durability of the entire engine system.

- Q: How does special steel perform in low-temperature applications?

- Special steel performs well in low-temperature applications due to its unique properties such as high strength, toughness, and resistance to brittleness. It retains its mechanical properties even at extremely cold temperatures, making it ideal for industries like aerospace, automotive, and energy where materials need to withstand challenging environments.

- Q: How does special steel contribute to the oil and gas industry?

- Special steel plays a crucial role in the oil and gas industry by offering enhanced strength, durability, and corrosion resistance needed for various applications. It is used in the construction of pipelines, drilling equipment, storage tanks, and offshore platforms, ensuring reliable and safe operations in harsh environments. Additionally, special steel's high heat resistance enables it to withstand extreme temperatures in refining processes, while its resistance to cracking and wear ensures the longevity of critical components. Overall, special steel contributes significantly to the oil and gas industry by providing the necessary materials for efficient and secure exploration, production, and transportation of oil and gas resources.

- Q: Can special steel be used in the textile industry?

- Yes, special steel can be used in the textile industry. Special steel, such as stainless steel, can be used in the production of various textile machinery components, including needles, pins, and loom parts. It offers durability, corrosion resistance, and strength, making it suitable for demanding textile manufacturing processes. Additionally, special steel can be used in the fabrication of textile machine frames and structures, providing the necessary stability and support.

- Q: What are the different surface hardening grades of special steel?

- There are several surface hardening grades of special steel, including case-hardening steels such as 1018, 8620, and 8620H, which are commonly used for applications requiring a hard outer layer and a tough core. Another grade is nitriding steel, such as 4140, 4340, and 410, which are specifically designed for nitriding processes to improve wear resistance. Additionally, tool steels like D2, A2, and O1 are often used for surface hardening applications due to their high hardness and wear resistance properties. Overall, the choice of surface hardening grade depends on the specific requirements of the application.

- Q: What are the applications of special steel in the agriculture sector?

- Special steel has various applications in the agriculture sector. It is often used in the manufacturing of agricultural machinery and equipment such as tractors, plows, harvesters, and irrigation systems. The high strength and durability of special steel make it ideal for withstanding the demanding conditions and heavy loads typically encountered in agricultural operations. Additionally, certain types of special steel, such as stainless steel, are corrosion-resistant, which is crucial for equipment exposed to moisture and chemicals in the farming environment.

- Q: How does special steel contribute to the aviation industry?

- Special steel plays a crucial role in the aviation industry by contributing to the safety, performance, and efficiency of aircraft. Firstly, special steel is used in the manufacturing of critical components of aircraft, including landing gears, engine parts, and structural elements. These components require materials with exceptional strength, durability, and resistance to fatigue and corrosion. Special steel, such as stainless steel or nickel-based alloys, offers these properties, ensuring the structural integrity and safety of the aircraft. Secondly, special steel enables the development of lightweight aircraft, which is a key requirement in the aviation industry. By utilizing high-strength alloys, manufacturers can reduce the weight of aircraft components without compromising their structural integrity. This results in fuel savings, extended range, and increased payload capacity, ultimately enhancing the efficiency of aircraft operations. Furthermore, special steel is crucial in enhancing the performance and reliability of aircraft engines. Steel alloys with high-temperature resistance and excellent mechanical properties are used in the production of turbine blades, combustion chambers, and exhaust systems. These components withstand extreme temperatures and stress levels, allowing engines to operate efficiently and reliably. Moreover, special steel contributes to the aviation industry by enabling innovative designs and technologies. With continuous advancements in material science, manufacturers are able to develop new steel alloys with improved properties, such as enhanced resistance to wear, thermal stability, or fatigue resistance. These innovations unlock new possibilities for aircraft design, performance, and fuel efficiency. In conclusion, special steel plays a vital role in the aviation industry by ensuring the safety, performance, and efficiency of aircraft. Its use in critical components, lightweight construction, engine manufacturing, and technological advancements contributes to the advancement of aviation, making air travel safer, more efficient, and more sustainable.

Send your message to us

Bearing Steel Rod 52100

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords