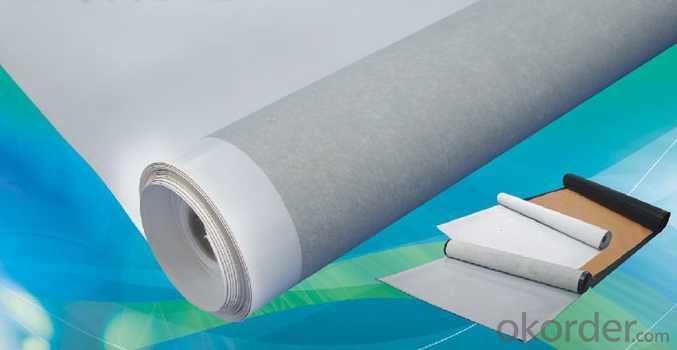

Basement Reinforced PVC Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Specification

No. | Item | L | N | W | ||||

I | II | I | II | I | II | |||

1 | Tensile strength N/cm ≥ | 100 | 160 | 8 | 12 | 100 | 160 | |

2 | fracture elongation %≥ | 150 | 200 | 200 | 200 | 150 | 200 | |

3 | Dimension Changing at heating %≤ | 1.5 | 1 | 3 | 2 | 1.5 | 1 | |

4 | Foldability at low temperature °C | -20 | -25 | -20 | -25 | -20 | -25 | |

5 | Water tightness | No leakage | No leakage | No Leakage | ||||

6 | Joint shear resistance (N/mm)≥ | 3 | 3 | 6 | ||||

7 | Thermal Ageing treatment | Appearance | no bubble | no bubble | no bubble | |||

Tensile strength changing rate % | ±25 | ±20 | ±25 | ±20 | ±25 | ±20 | ||

Breaking elongation changing rate% | ||||||||

8 | Chemical corrosion resistance | foldability at low temperature °C | -15 | -20 | -15 | -20 | -15 | -20 |

Tensile strength changing rate % | ±25 | ±20 | ±25 | ±20 | ±25 | ±20 | ||

Breaking elongation changing rate% | ||||||||

9 | Artificial climate accelerated aging | foldability at low temperature °C | -15 | -20 | -15 | -20 | -15 | -25 |

Tensile strength changing rate % | ±25 | ±20 | ±25 | ±20 | ±25 | ±20 | ||

Breaking elongation changing rate% | ||||||||

Applications

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

Features

1. Good combination of high elasticity and tensile strength.

2. Fine resistance to static electricity.

3. Excellent resistance to ageing / weathering.

4. Durable, the effective age can be more than 20 years used on exposed surfaces, used on non-exposed surfaces, it can reach 50 years.

5. Fine flexibility at low temperature, adaptable to cold conditions.

6. Root-resistance can be used on the planting roofs.

7. Fine puncture resistance, joint peel strength and joint shear strength.

8. Fine UV-resistance, no pollution to environment.

9. Easily welding, installing, secure.

10. Easy treatments to the delicate parts of corners and edges.

11. Convenient maintenance with low cost.

RFQ

1. What is your MOQ?

--Our MOQ is 5000 m2

2. Can you provide sample?

--Yes, samples are in stock. we can offer free sample for you.

3. Do you offer OEM service?

--Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can waterproofing membranes be used on expansion joints?

- Indeed, expansion joints can benefit from the utilization of waterproofing membranes. These joints serve the purpose of accommodating movement while safeguarding against harm brought about by the expansion or contraction of construction materials due to thermal fluctuations. By applying waterproofing membranes to these joints, a protective barrier is established, effectively impeding the infiltration of water. This serves to preserve the joint's structural integrity and prevent water-induced damage to adjacent areas. It is imperative to carefully select a flexible waterproofing membrane that can endure the joint's movements without incurring cracks or deterioration. Furthermore, the employment of proper installation techniques is crucial to ensuring a watertight seal around the expansion joint.

- Q: Are waterproofing membranes resistant to seawater?

- Yes, waterproofing membranes are generally resistant to seawater. They are designed to provide a barrier against water infiltration, including salty seawater, and are commonly used in various marine applications.

- Q: How does a waterproofing membrane perform in areas with chemical exposure or solvents?

- A waterproofing membrane is designed to provide protection against water penetration, but it may not be effective against chemical exposure or solvents. Chemicals can potentially degrade or damage the membrane, compromising its waterproofing capabilities. It is important to select a membrane specifically designed for chemical resistance if the area is expected to have chemical exposure or solvents.

- Q: Are there any specific maintenance requirements for a waterproofing membrane?

- Yes, there are specific maintenance requirements for a waterproofing membrane. Regular inspections should be conducted to check for any signs of damage or deterioration, such as cracks or leaks. Any debris or standing water should be promptly removed to prevent potential damage. Additionally, it is important to follow the manufacturer's guidelines for cleaning and maintenance, which may include periodic cleaning with mild detergents and avoiding the use of harsh chemicals or abrasive cleaning tools.

- Q: Does a waterproofing membrane provide any additional structural reinforcement?

- No, a waterproofing membrane does not provide any additional structural reinforcement. The primary purpose of a waterproofing membrane is to prevent the ingress of water or moisture into a building or structure. It acts as a barrier, typically applied on the exterior surface, to keep water out and protect the underlying materials from damage caused by water. While it can enhance the durability and longevity of a structure by preventing water-related issues such as leakage, dampness, or mold growth, it does not contribute to the structural integrity or strength of the building. Structural reinforcement is typically achieved through the use of materials like steel, concrete, or other load-bearing components, which are designed to carry and distribute the weight and loads of the structure.

- Q: Can a waterproofing membrane be used for bridge decks?

- Yes, a waterproofing membrane can be used for bridge decks. Waterproofing membranes are commonly used in bridge construction to protect the bridge deck from moisture, preventing water damage and increasing the lifespan of the bridge.

- Q: Does a waterproofing membrane need to be primed before installation?

- Yes, a waterproofing membrane typically requires priming before installation. Priming helps improve the adhesion of the membrane to the substrate and ensures proper bonding, enhancing the overall effectiveness and durability of the waterproofing system.

- Q: Where are waterproofing membranes commonly used?

- Waterproofing membranes find wide application in various scenarios, serving to thwart water infiltration and safeguard structures against moisture-induced harm. The prevalent areas where they are employed include: 1. Basements: Waterproofing membranes are extensively utilized in basements to counter water seepage via foundation walls and floors. They establish a barrier that repels water, thereby promoting a dry and inhabitable space. 2. Roofs: Roofs often make extensive use of waterproofing membranes to shield buildings against rain, snow, and other adverse elements. Positioned beneath the roofing materials, they act as a barricade, averting water penetration and ensuring roof integrity. 3. Bathrooms and wet areas: Bathrooms, showers, and other wet regions necessitate the presence of waterproofing membranes to prevent water intrusion into walls and floors. By creating an impermeable seal, they effectively thwart the growth of mold, water damage, and structural complications. 4. Balconies and terraces: Balconies, terraces, and other outdoor spaces commonly benefit from the application of waterproofing membranes. Their presence safeguards against water-induced deterioration by constituting a protective layer that bars water penetration. 5. Swimming pools: Swimming pool construction heavily relies on waterproofing membranes to prevent water leakage. By being applied to the pool shell, they provide a water-tight seal, ensuring structural integrity and preventing water seepage. 6. Tunnels and underground structures: Tunnels and underground structures employ waterproofing membranes to shield against groundwater infiltration. These membranes serve as a waterproof barrier, effectively preventing water damage and structural compromise. 7. Planter boxes and green roofs: Planter boxes and green roofs often incorporate waterproofing membranes to avert water seepage into building structures. By establishing a barrier, they retain moisture within the planter or green roof while blocking infiltration into the building. In summary, waterproofing membranes assume a vital role in diverse construction endeavors, safeguarding structures, and prolonging their lifespan by curtailing water damage and moisture-related issues.

- Q: Can a waterproofing membrane be used for warehouses or storage facilities?

- Warehouses or storage facilities can utilize a waterproofing membrane. These membranes are specifically designed to safeguard structures against water damage by creating a barrier that prevents moisture infiltration. In warehouses and storage facilities, there are often large areas that are vulnerable to potential leaks or seepage, such as roofs, walls, and floors. By installing a waterproofing membrane, these structures can be effectively shielded from water intrusion, thereby preventing harm to stored goods and maintaining the facility's integrity. Waterproofing membranes come in various types, including bituminous, liquid-applied, or sheet membranes, providing flexibility in selecting the most appropriate option based on the specific requirements of the warehouse or storage facility. Furthermore, waterproofing membranes offer additional advantages such as thermal insulation and resistance to chemicals, further enhancing their value in ensuring the durability and functionality of warehouses or storage facilities.

- Q: Are waterproofing membranes resistant to soil chemicals?

- Yes, waterproofing membranes are generally resistant to soil chemicals. These membranes are designed to withstand various environmental conditions, including exposure to soil chemicals, without compromising their effectiveness or integrity.

Send your message to us

Basement Reinforced PVC Waterproofing Membrane

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords