ASTM Standard Checker Five Bar Painted Aluminum Sheets in Shreveport

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

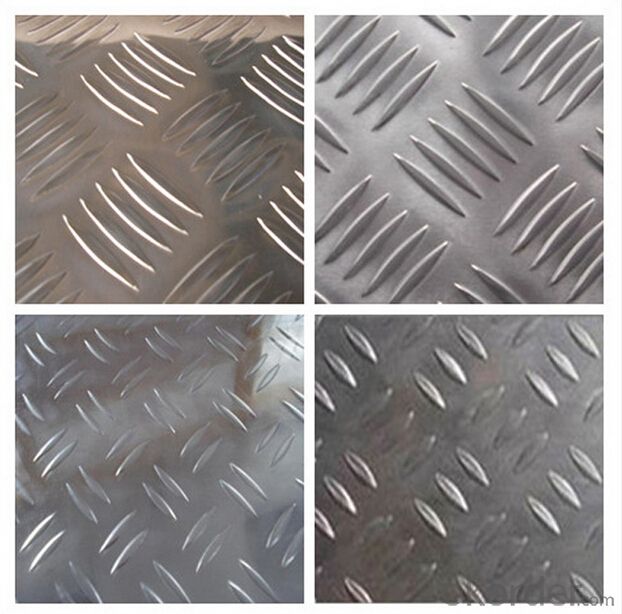

1.Structure of ASTM Standard Checker Five Bar Aluminum Tread Plate Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of ASTM Standard Checker Five Bar Aluminum Tread Plate :

1). Aircraft, automobile, train

2). Building wall, ceilings, roofing, furniture cabinet, lighting plate

3). Shipping plate, solar reflective plate,Corner protector, insulation material

4). Beverage bottle, cap, ring-pull, cosmetics shell and cover

5). Aluminum tread/embossed plate, quenched and pre-stretched plate

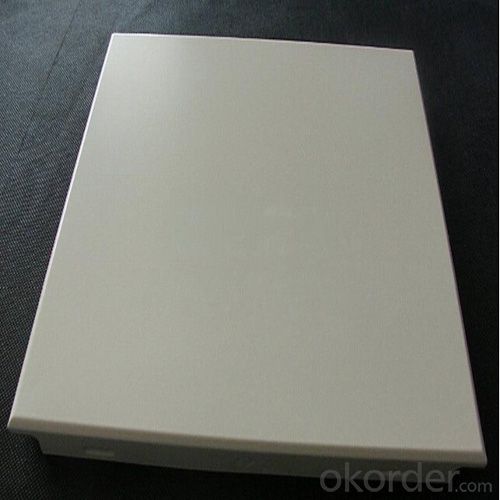

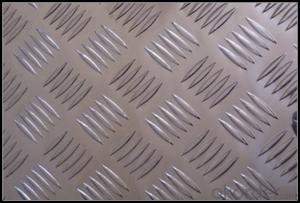

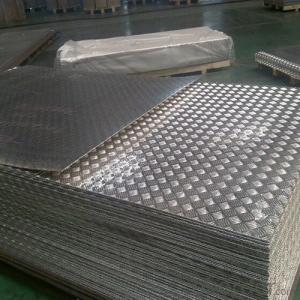

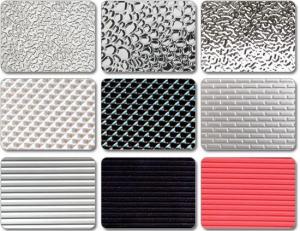

3. ASTM Standard Checker Five Bar Aluminum Tread Plate Images:

4. ASTM Standard Checker Five Bar Aluminum Tread Plate Specification:

embossing Aluminum Tread Sheet | |

Alloy | 1100,1060, 3003, 5005 5052 |

Temper | H14,H18,H24,H32 |

Thickness (mm) | 1.5mm to 6mm |

Width (mm) | Up to 1500mm |

Length (mm) | Up to 6000mm |

Standard | EN standard ASTM standard |

MOQ | 5ton |

Application | 1)Decorated inside and outside the car /building frame, windows, doors, ceiling, decorating panel and curtain wall 2)Household appliances: refrigerators, microwave ovens, audio equipment, etc. |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: 1 ton of aluminium=______ tons of Alumina

- Aluminium is a reactive metal and it is hard to extract it from its ore, aluminium oxide (Al2O3). Direct reduction, with carbon for example, is not economically viable since aluminium oxide has a melting point of about 2000 °C. Therefore, it is extracted by electrolysis — the aluminium oxide is dissolved in molten cryolite and then reduced to the pure metal. By this process, the actual operational temperature of the reduction cells is around 950 to 980 °C. Cryolite was originally found as a mineral on Greenland, but has been replaced by a synthetic cryolite. Cryolite is a mixture of aluminium, sodium, and calcium fluorides: (Na3AlF6). The aluminium oxide (a white powder) is obtained by refining bauxite, which is red since it contains 30 to 40% iron oxide. This is done using the so-called Bayer process. Previously, the Deville process was the predominant refining technology. The electrolytic process replaced the W?hler process, which involved the reduction of anhydrous aluminium chloride with potassium. Both of the electrodes used in the electrolysis of aluminium oxide are carbon. Once the ore is in the molten state, its ions are free to move around. The reaction at the negative cathode is Al3+ + 3 e- → Al Here the aluminium ion is being reduced (electrons are added). The aluminium metal then sinks to the bottom and is tapped off. At the positive electrode (anode) oxygen gas is formed: 2 O2- → O2 + 4 e- This carbon anode is then oxidised by the oxygen. The anodes in a reduction must therefore be replaced regularly, since they are consumed in the process: O2 + C → CO2 So, as you can see, the exact tonnage required to produce 1 ton of aluminum is very sketchy at best...

- Q: I'm wanting to buy colorguard poles, and I found some good deals on aluminum and fiberglass ones. But what are the pros and cons of each one?

- I'd say fiberglass because... - Durability - Aluminum is a very bendable metal. It dents, it bends, and it breaks easier than any other metal pole you'll find. This is because it's a very low density metal. - Flexibility = more dramatic twirling due to pole flex, and it's less breakable. - Counter Weight = A flag on one side of the pole would be harder to move around swiftly without a counterweight. Thus a heavier pole would entail having a center of gravity on the flag pole closer to the hand, making it easier to maneuver the flag, but the pole would be harder to lift as a whole. I'm no expert on colorguard poles, though. Fiberglass has come a long way. While aluminum is always the same material, fiberglass is a constantly evolving building material.

- Q: What is the melting point of aluminum sheets?

- The melting point of aluminum sheets is approximately 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Are aluminum sheets suitable for laser cutting?

- Yes, aluminum sheets are suitable for laser cutting. Aluminum is a commonly used material in laser cutting due to its excellent reflective properties, high thermal conductivity, and low melting point. These characteristics make it an ideal material to be cut by a laser beam. Laser cutting provides precise and clean cuts on aluminum sheets, allowing for intricate designs and complex shapes to be easily achieved. Additionally, laser cutting of aluminum sheets is a fast and efficient process, offering high productivity and cost-effectiveness.

- Q: This question asks for methods to clean aluminum sheets to preserve their appearance.

- <p>To clean aluminum sheets and maintain their appearance, follow these steps: 1. Use a mild detergent mixed with warm water to create a cleaning solution. 2. Gently scrub the aluminum sheets with a soft cloth or sponge to avoid scratching the surface. 3. Rinse thoroughly with clean water to remove any detergent residue. 4. Dry the sheets immediately with a soft, dry cloth to prevent water spots. 5. For stubborn stains, use a non-abrasive cleaner specifically designed for aluminum. 6. Avoid using harsh chemicals or abrasive materials that can damage the aluminum's finish. Regular cleaning will help preserve the appearance and longevity of aluminum sheets.</p>

- Q: What are the different machining options for aluminum sheets?

- Depending on the specific requirements of the project and the desired outcome, there are several machining options available for aluminum sheets. Some commonly used methods for machining aluminum sheets include: 1. Cutting: Aluminum sheets can be cut using various techniques such as shearing, sawing, or laser cutting. Shearing involves applying high force with a shearing machine to achieve a clean and straight cut. Sawing utilizes a saw blade to cut through the aluminum sheet, while laser cutting uses a high-powered laser beam to melt or vaporize the aluminum for precise and accurate cuts. 2. Drilling: Drilling is a frequently employed machining option to create holes in aluminum sheets. This process involves using a drill bit to remove material from the sheet and create holes with the desired diameter. Different drill bits can be utilized to achieve specific hole sizes and shapes. 3. Milling: Milling is a versatile machining option that can be used to create intricate shapes and contours in aluminum sheets. This process involves using a rotating cutting tool to remove material from the sheet, resulting in precise and accurate finishes. Depending on the project's complexity, milling can be performed using various types of milling machines, such as vertical milling machines or CNC milling machines. 4. Turning: Turning is another machining option commonly employed for aluminum sheets, particularly when shaping cylindrical or conical forms. This process involves rotating the aluminum sheet against a cutting tool, which removes material and shapes the sheet according to the desired dimensions. Turning can be carried out manually on lathes or using CNC turning machines for higher precision. 5. Bending: Bending is a frequently used machining option to create curved or angled shapes in aluminum sheets. This process involves applying force to the sheet, causing it to deform and take on the desired shape. Bending can be done manually using tools like a brake press or using hydraulic or CNC press brakes for more accurate and consistent results. These are just a few of the machining options available for aluminum sheets. The choice of method will depend on factors such as the desired outcome, project complexity, and available resources. It is crucial to select the most suitable machining option to efficiently and effectively achieve the desired results.

- Q: What is the minimum bending radius for aluminum sheets?

- Several factors, such as sheet thickness, alloy type, and bending method, determine the minimum bending radius for aluminum sheets. However, as a rule of thumb, the minimum bending radius is usually 1.5 to 2 times the sheet thickness. For instance, if your aluminum sheet is 1mm thick, the minimum bending radius would be approximately 1.5 to 2mm. It's worth mentioning that these values may vary, so it is advisable to consult the manufacturer's or a professional's specific material and bending guidelines for the best outcomes.

- Q: Curtain wall aluminum plate reinforcement spacing between the number of appropriate, the country has no standard?

- As to the stiffener of the aluminum veneer, what are the following points?:1, aluminum reinforcement spacing is generally around 600mm, in order to ensure the aluminum plate in the positive and negative pressure conditions within the scope of deformation. When aluminum plate is welded, there is internal stress due to welding deformation (this internal stress can not be completely eliminated for a long time), and the rigidity of reinforcing bar should also be increased.2. The sectional dimension and spacing of stiffeners shall be determined according to the calculated wind pressure of the aluminum plate. But it is worth noting that the reinforcement calculation of single aluminum plate strengthening is different from the glass curtain wall, first, its strength is certainly no problem (still not seen the wind blowing broken plate, there is no joke) deflection possibility, bend off and windy weather also very few people to pay attention to the single aluminum plate plate surface after deformation the scenery. Therefore, the calculation of deflection of stiffeners are considered under the condition of wind strength and deflection when the winds of aluminum can cause permanent plastic deformation.In fact, aluminum veneer manufacturers generally use the single aluminum plate edge folding groove made of aluminum and 20*40*20, installed in the distance about 600mm. Also useful for profile (grooved aluminum) stiffenersThe spacing between stiffeners is very important to the cost of production. Generally speaking, the spacing of stiffeners will be changed from 600 to 350, and the cost will be increased by 8~15 yuan / square meter

- Q: I saw a nice looking set of cast aluminum pots for a very good price. They feel very heavy. But I remember hearing that aluminum is not healthy so I am wary of buying them. Any advice would be appreciated.

- Cast Aluminum Pots

- Q: Are aluminum sheets suitable for chemical storage tanks?

- Depending on the specific requirements of the chemical being stored, aluminum sheets may be a suitable option for chemical storage tanks. Aluminum is renowned for its exceptional resistance to corrosion, making it well-suited for the storage of numerous chemicals. It develops a protective oxide layer that effectively prevents further corrosion, even in harsh environments. Nevertheless, it is vital to take into account the compatibility between the chemical and aluminum. Some chemicals, such as strong acids or bases, can react with aluminum, leading to corrosion or other undesirable reactions. In such instances, alternative materials like stainless steel or fiberglass-reinforced plastic (FRP) might be more appropriate. Furthermore, careful consideration should be given to the thickness and grade of the aluminum sheets, depending on the specific chemical being stored and the intended use of the tank. For highly corrosive or hazardous chemicals, thicker sheets may be necessary, while thinner sheets may suffice for less aggressive substances. In conclusion, aluminum sheets can be a viable choice for chemical storage tanks, provided that careful evaluation of chemical compatibility is conducted and the appropriate thickness and grade of aluminum are selected to ensure safe and reliable storage.

Send your message to us

ASTM Standard Checker Five Bar Painted Aluminum Sheets in Shreveport

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords