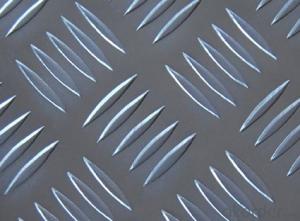

Aluminum Sheets in Nevada - Alu Plate with Five-bars Pattern

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Alu Plate

Aluminum trade plate have great suctility,heat conductivity, anti-corrosion and moisture resistance properties.

Alloy: AA1050,1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011, etc

Temper: H14/16/18/22/24/32,HO etc.

Thickness:0.2mm—100mm

Width:100mm—2300mm (Can be slitted)

Application:

Anti-sliperypurpose in vehicles, packing and appliance, decorative purpose

- Q: For a high school Chemistry course I made soap for a project. Before doing this, thank god, i learned that one should never use an aluminum container to mix the lye (NaOH) and water. Now, I need to know why. I know it eats away at the container but i can't figure out why. It goes against everything I've learned so far. At first i thought it was because Aluminum was, for some strange reason :o, more reactive than Sodium therefore replacing it in the reaction but that turned out not to be true. Does anyone have an idea of why? Thanks

- Under normal circumstances, aluminum does not react with water, as an impermeable protective layer composed of aluminum hydroxide either forms within seconds or is already in place. With the addition of sodium hydroxide, the formation of a protective layer is prevented. With the production of aluminates [ Al(OH)4 ]-, the amphoteric (capable of acting as either an acid or a base) aluminum hydroxide Al(OH)3 goes in solution: 2 Al + 6 H2O -- 2 Al(OH)3 + 3 H2 Al(OH)3 + NaOH -- Na+ + [ Al(OH)4 ]- A layer of aluminum oxide previously formed by passive corrosion is dissolved by the addition of sodium hydroxide. For this reason, the reaction takes place at the beginning relatively slowly: Al2O3 + 2 NaOH + 3 H2O -- 2 Na+ + 2 [ Al(OH)4 ]- The aluminum completely dissolves and the water acts here too as an acid (for an analog, see Experiment 4.4.1). This reaction is used in drain cleaners. They are mostly made out of strong alkalis, to which alumunim or zinc has been added. The alkalis break down organic residues chemically. In addition, the formation of hydrogen leads to a bubbling effect which adds an additional mechanical cleaning mechanism. The big problem here is the formation of hydrogen gas (as well as some heat). The hydrogen gas is flammable, and if it's in a closed container, will explode

- Q: This question asks for a list of aluminum sheet types suitable for exterior applications, indicating a need for knowledge on construction materials.

- <p>Aluminum sheets for exterior use come in various types, each with specific properties and applications. Some common types include: 1. Mill Finish Sheets: These have a natural aluminum finish and are corrosion resistant. 2. Anodized Aluminum Sheets: They offer enhanced durability and resistance to weathering. 3. Painted Aluminum Sheets: These are coated with a protective paint layer for improved aesthetics and weather resistance. 4. Embossed Aluminum Sheets: They provide a textured surface and are used for both aesthetic and functional purposes. 5. Perforated Aluminum Sheets: These have holes and are used for ventilation and light filtration. 6. Aluminum Composite Material (ACM) Sheets: These are lightweight and used for cladding due to their strength and low weight. Each type is chosen based on the specific requirements of the project, such as weather conditions, aesthetic preferences, and structural needs.</p>

- Q: What is the typical modulus of elasticity for aluminum sheets?

- The typical modulus of elasticity for aluminum sheets is around 70 GPa (Gigapascals).

- Q: Aluminum alloy cable tray is made of a series of aluminum sheets, a series of pure aluminum aluminum plate can do?

- 6 Department of the bar, pure aluminum is too soft, in fact, the price of 6 series with pure aluminum prices on the strength of almost guaranteed.

- Q: is aluminum foil spacer poisonous after heating?

- many baked food will use aluminum foil.

- Q: Are aluminum sheets suitable for food processing applications?

- Yes, aluminum sheets are suitable for food processing applications. Aluminum is known for its excellent thermal conductivity and corrosion resistance, making it ideal for food industry processes such as cooking, baking, and packaging. Additionally, aluminum is a lightweight and cost-effective material that can be easily formed into various shapes and sizes, making it convenient for food processing equipment and utensils.

- Q: What is the shear strength of aluminum sheets?

- The shear strength of aluminum sheets varies based on the specific alloy and temper of the material. In general, aluminum alloys have a lower shear strength compared to steels, but higher than most other non-ferrous metals. The shear strength can range from around 30 to 60 MPa (MegaPascals) for commonly used aluminum alloys in sheet form. However, it should be noted that these values can change depending on factors like thickness, surface finish, manufacturing process, and any heat treatments applied to the aluminum sheets. Therefore, it is recommended to refer to the specific material datasheet or reach out to the manufacturer for accurate and detailed information regarding the shear strength of a particular aluminum sheet.

- Q: What is the typical thermal conductivity of aluminum sheets?

- Aluminum sheets usually exhibit a thermal conductivity ranging from 205 to 230 watts per meter-kelvin (W/mK). Thanks to this remarkable thermal conductivity, aluminum serves as an exceptional conductor of heat. Hence, it finds widespread usage in various applications that prioritize efficient heat transfer, including heat sinks, power transmission lines, and cooking utensils.

- Q: Can aluminum sheets be used in construction?

- Construction can indeed utilize aluminum sheets. Aluminum, a versatile and lightweight material, possesses numerous advantageous properties for construction purposes. Its corrosion resistance allows for both indoor and outdoor applications. Moreover, aluminum sheets exhibit a high strength-to-weight ratio, granting them durability and strength while remaining relatively lightweight. This characteristic proves advantageous in construction projects where weight is a consideration. Furthermore, aluminum is non-toxic and highly recyclable, making it an environmentally conscious option. When combined with its aesthetic appeal and ease of fabrication, aluminum sheets become a favored choice for a variety of construction applications such as roofing, cladding, wall panels, window frames, and more.

- Q: Are 101 aluminum sheets suitable for food-grade applications?

- Indeed, 101 aluminum sheets prove to be fitting for food-grade applications. 101 aluminum, being a commercially pure alloy, exhibits remarkable resistance against corrosion and possesses commendable formability. Its low chemical reactivity ensures that it remains unresponsive to acidic or alkaline substances, thus rendering it secure for usage in food-grade applications. Furthermore, the convenience of effortlessly cleaning and sanitizing 101 aluminum sheets designates them as an optimal selection for food processing, packaging, and storage purposes.

Send your message to us

Aluminum Sheets in Nevada - Alu Plate with Five-bars Pattern

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords