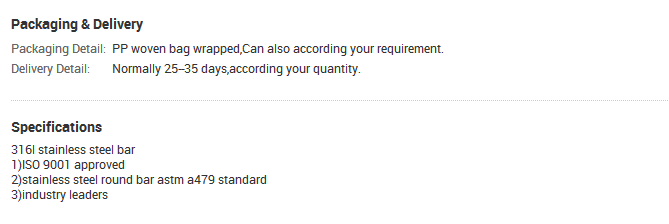

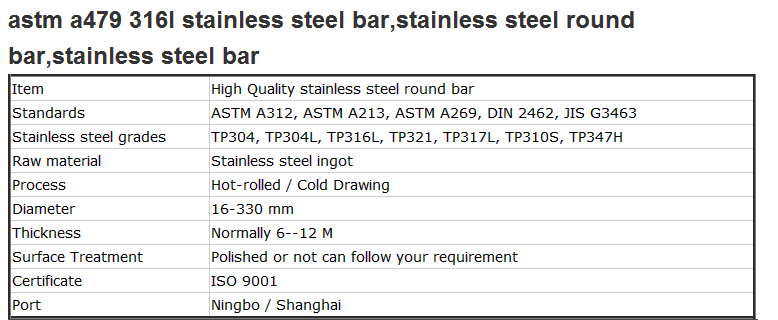

astm a479 316l stainless steel bar,stainless steel round bar,stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: What is the significance of the schedule in stainless steel pipes?

- The thickness of the pipe walls is what the schedule in stainless steel pipes refers to. It plays a crucial role in determining the pipe's strength, durability, and ability to handle pressure. The schedule is represented by a numerical value, such as Schedule 10, Schedule 40, or Schedule 80, which indicates the thickness of the pipe. The schedule's importance lies in its impact on the pipe's ability to withstand different conditions and applications. A higher schedule number means a thicker wall, resulting in increased strength and resistance to both internal and external pressures. This makes stainless steel pipes with a higher schedule suitable for applications that involve high pressure and high temperature, such as industrial processes, oil and gas pipelines, and chemical processing plants. Additionally, the schedule also affects the flow capacity of the pipe. Thicker-walled pipes have a smaller internal diameter, which reduces the flow rate compared to pipes with thinner walls. This factor is crucial when considering the fluid flow requirements in plumbing systems, HVAC installations, and other applications. The choice of the appropriate schedule for stainless steel pipes depends on specific project requirements, including pressure, temperature, and flow conditions. It is essential to select the correct schedule to ensure the pipe can safely and efficiently handle the intended application. To summarize, the significance of the schedule in stainless steel pipes lies in its influence on strength, pressure handling capabilities, and flow capacity. By understanding the schedule, engineers and professionals can make informed decisions when selecting and installing stainless steel pipes for various industrial, commercial, and residential applications.

- Q: Can stainless steel pipes be used for brewery and beverage industry applications?

- Yes, stainless steel pipes can be used for brewery and beverage industry applications. Stainless steel is highly resistant to corrosion, making it suitable for handling liquids and beverages. It is also easy to clean and maintain, ensuring the hygienic requirements of the industry are met. Stainless steel pipes are commonly used in these industries due to their durability, longevity, and compatibility with various fluids.

- Q: What's the easiest way to distinguish between stainless steel 202 and 304?

- 304 stainless steel performance is better than 202 stainless steel, the price is more expensive than 202 stainless steel.

- Q: Advantages and disadvantages of PPR lined stainless steel pipe and PPR aluminium plastic pipe

- 1 、 aluminum plastic composite pipe including lap welding aluminum plastic composite pipe and butt welding aluminum plastic composite pipe, butt welding, the thickness of the aluminum strip and welding process requirements are relatively high.2, the existence of lap welding aluminum layer, increased the modulus of the pipe, and the wall thickness is more thick, installation of pipe is more difficult to bend, need to use more pipe fittings for connection, therefore, field construction is more difficult than PP-R. And the plastic aluminum steady state composite tube must first strip off the outer protective layer, the adhesive layer and the aluminum layer before welding, and then can connect. If the adhesive layer is not clean, it will lead to welding unreliable and leak point.

- Q: What is the difference between Type 409 and Type 410 stainless steel pipes?

- Type 409 stainless steel pipes are commonly used in automotive exhaust systems due to their excellent resistance to high temperatures and corrosion. On the other hand, Type 410 stainless steel pipes are known for their higher strength and hardness, making them suitable for applications that require increased durability and resistance to wear and abrasion.

- Q: What are the different finishes available for stainless steel pipes?

- Stainless steel pipes come in various finishes, each offering a distinct appearance and level of protection against corrosion. 1. Brushed Finish: By utilizing a fine abrasive material, the surface of the stainless steel pipe is brushed to create a textured and dull look. This finish effectively conceals scratches and fingerprints, making it a popular choice for projects that prioritize aesthetics, such as architectural designs. 2. Mirror Finish: Also referred to as a polished or reflective finish, this option involves polishing the surface of the stainless steel pipe to achieve a highly reflective shine. It provides a smooth and easily cleanable surface, commonly used for decorative purposes like handrails and furniture. 3. Satin Finish: Similar to the brushed finish, the satin finish employs a fine abrasive material to create a smooth and dull appearance. It offers a slightly more refined look compared to the brushed finish and is frequently utilized in applications where corrosion resistance is crucial, such as the food and beverage industry. 4. Embossed Finish: This finish entails imprinting a pattern onto the surface of the stainless steel pipe, adding texture and visual interest. It is often employed in decorative applications like wall panels or elevator interiors. 5. Bead Blasted Finish: Achieved by propelling small glass beads at high pressure onto the stainless steel pipe's surface, this finish creates a uniform and matte appearance. It is commonly used in architectural projects as it provides a unique texture and effectively conceals fingerprints. 6. Passivated Finish: The passivation process involves chemically removing contaminants from the surface of the stainless steel pipe to enhance its corrosion resistance. This finish is frequently employed in applications where the pipes are exposed to harsh environments or chemicals. It is crucial to consider the specific application and aesthetic preferences when selecting a finish for stainless steel pipes. Each finish has its own pros and cons, so factors like durability, maintenance, and the intended use of the pipe should be taken into account before making a decision.

- Q: What is the difference between seamless and cold-drawn stainless steel pipes?

- Seamless and cold-drawn stainless steel pipes are two different types of stainless steel pipes that vary in their manufacturing processes and properties. Seamless stainless steel pipes are manufactured without any welding or seams. They are made by piercing a solid cylindrical billet or ingot of stainless steel and then rolling it into a hollow tube shape. This seamless manufacturing process ensures that there are no weak points or areas prone to leakage, making seamless pipes highly durable and reliable. They also have a smoother interior surface, which allows for efficient fluid flow and reduces the risk of corrosion. On the other hand, cold-drawn stainless steel pipes are manufactured by pulling or drawing a solid stainless steel billet through a series of dies at room temperature. This process helps in achieving precise dimensions and a smooth surface finish. Cold-drawn pipes are typically used in applications where tight tolerances and a high-quality surface finish are required. They are known for their superior dimensional accuracy, excellent surface finish, and increased strength. In terms of properties, seamless stainless steel pipes offer better resistance to corrosion, higher strength, and increased pressure rating compared to cold-drawn pipes. The absence of welds also makes seamless pipes less prone to cracking or failure under high-pressure environments. On the other hand, cold-drawn stainless steel pipes are known for their excellent surface finish, close dimensional tolerances, and improved mechanical properties, making them suitable for applications that require precise measurements and a smooth appearance. In summary, the main difference between seamless and cold-drawn stainless steel pipes lies in their manufacturing processes, resulting properties, and applications. Seamless pipes are manufactured without any welding or seams, offering better resistance to corrosion and higher strength, while cold-drawn pipes are made by pulling solid stainless steel through dies, providing excellent surface finish, dimensional accuracy, and improved mechanical properties.

- Q: What is the average lifespan of stainless steel pipes?

- The average lifespan of stainless steel pipes can vary depending on various factors such as the quality of the materials used, the environment in which they are installed, and the maintenance practices followed. However, on average, stainless steel pipes can last anywhere from 50 to 100 years or more with proper care and maintenance.

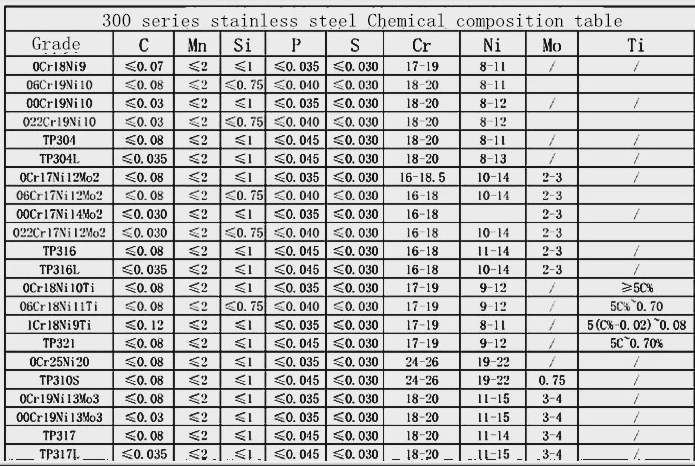

- Q: How do you choose the right stainless steel grade for a specific application?

- When choosing the right stainless steel grade for a specific application, several factors need to be considered. These include the desired corrosion resistance, temperature resistance, mechanical properties, and cost-effectiveness required for the application. It is crucial to thoroughly understand the application's environmental conditions, such as exposure to chemicals, moisture, or high temperatures, as this will determine the level of corrosion resistance needed. Additionally, considering the required strength, toughness, and hardness of the stainless steel for the specific application is important. Balancing these factors with the cost-effectiveness of the grade will help in choosing the most suitable stainless steel grade for the application. Consulting with metallurgical experts or referring to industry standards and guidelines can provide further guidance in making an informed decision.

- Q: Can stainless steel pipes handle high temperatures?

- Stainless steel pipes possess the ability to endure high temperatures. The exceptional heat resistance of stainless steel makes it suitable for a wide range of applications involving elevated temperatures. The maximum temperature the pipes can withstand is determined by the specific grade of stainless steel employed. For example, austenitic stainless steel grades like 304 and 316 are typically capable of handling temperatures up to approximately 1600°F (870°C), whereas higher alloyed grades such as 310 and 321 can withstand even higher temperatures. This heat resistance is attributed to the presence of chromium and other alloying elements in stainless steel, which create a protective oxide layer that prevents corrosion and oxidation at high temperatures. Consequently, stainless steel pipes find common use in industries like petrochemical, power generation, and heat exchangers, where high temperatures are prevalent.

Send your message to us

astm a479 316l stainless steel bar,stainless steel round bar,stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords