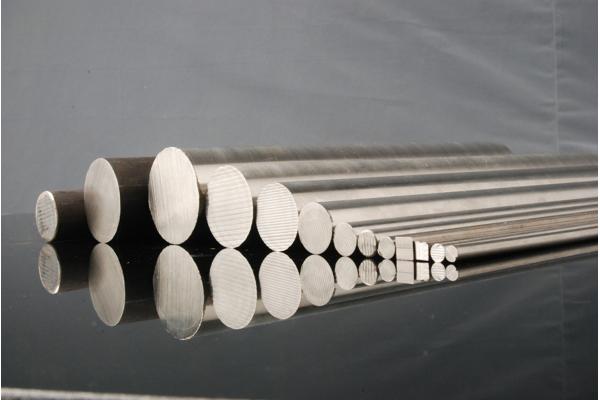

wholesale Astm 316 /316L Stainless Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Stainless Steel Bar

1.Cold roll cold draw pipe&tube

2.Grade: TP304,TP316L

3.Honor: CE/PED,AB

4.STANDARD: ASTM 312/213/269

Description:

| Series | Top Quility steel Rod |

| Grade | 300 series(304, 304 L,304H,310,310S,316, 316 L,317L,321etc.) |

| Technics | Hot-rolled, Hot-forged, Cold-drawn, Centerless Gringing |

| Surface | Peeled, Bright, Polish |

| Diamete Rang | Peeled bright round bar: 3-400mm |

| Hot-rolled bar: 3-130mm | |

| Hot- forged bar: 130-400mm | |

| Cold-drawn: 3-40mm | |

| Centerless grinding bright round bar: 3-100mm | |

| Dia torlarance:H9-K12 | |

| Length | Radom length, Specified length, Multiple length ( no more than 9m) |

| Usage | These products are widely supplied to areas of machine-made industry, chemical industry, |

| shipping industry, rchitecture, food industry, household products etc | |

| Packaging | Standard export packing, according to customer's requirment |

| Delivery Time | up to the order quantity |

| Certification | CE/PED,ABS, DNV ,GL,LR |

| Application | Pipe and Tubes for petrochemical industry,pharmaceutical industry ,food industry, |

| aviation and aerospace industry,architectural decoration industry |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Are steel round bars suitable for machining?

- Indeed, machining is a suitable application for steel round bars. Due to their remarkable machinability, steel round bars are frequently employed in diverse machining procedures. These bars can be effortlessly molded, sliced, bored, and rotated using various machining methods like milling, turning, drilling, and grinding. By offering commendable dimensional stability, exceptional strength, and outstanding wear resistance, steel round bars prove to be an ideal choice for machining operations. Moreover, the availability of different grades and alloys further expands the scope of machining applications in industries spanning automotive, aerospace, construction, and manufacturing.

- Q: What's the difference between a round tube and a round tube?

- Round steel is generally refers to steel, the surface is not threaded, different from round steel pipe, round tube is round tube.

- Q: Are steel round bars suitable for plumbing applications?

- Yes, steel round bars are suitable for plumbing applications. They are commonly used in plumbing systems for their strength, durability, and resistance to corrosion. Steel round bars can be easily shaped and welded to create various plumbing components such as pipe fittings, supports, and brackets. Additionally, their high tensile strength makes them capable of withstanding the pressure and load requirements in plumbing systems.

- Q: Can steel round bars be used for shafting applications?

- Indeed, shafting applications can make use of steel round bars. In industries like automotive, construction, and manufacturing, steel round bars are frequently employed as material for shafting. These bars possess impressive mechanical properties, durability, and high strength, enabling them to effectively transmit power and rotational motion in machines and equipment. Furthermore, steel round bars can be machined to precise dimensions, subjected to heat treatment for enhanced hardness, and coated to provide protection against corrosion. Moreover, they are obtainable in a variety of grades and alloys, catering to specific application requirements. In summary, due to their inherent strength and versatility, steel round bars are a dependable choice for shafting applications.

- Q: Can steel round bars be used for making tools or machinery parts?

- Yes, steel round bars can be used for making tools or machinery parts. Steel round bars are known for their high strength, durability, and resistance to wear and tear. These properties make them ideal for applications in the manufacturing of tools and machinery parts that require high strength and reliability. Steel round bars can be machined, forged, or heat-treated to achieve the desired shape and properties required for specific tools or machinery parts. Additionally, steel round bars come in various grades, each with its own specific properties, allowing manufacturers to select the most suitable grade for their specific application. Overall, steel round bars are a versatile and commonly used material in the manufacturing industry for making tools and machinery parts.

- Q: What are the different types of steel round bar surface finishes for improved aesthetics?

- There are several different types of steel round bar surface finishes that can be used to enhance the aesthetic appeal of the material. These finishes are often chosen based on the desired look and feel of the steel, as well as the intended application. Some of the most common surface finishes for steel round bars include: 1. Polished: This finish involves a series of abrasive processes that result in a smooth, reflective surface. It is commonly used in applications that require a high level of visual appeal, such as architectural structures or decorative pieces. 2. Brushed: This finish is achieved by brushing the steel surface with a wire brush or abrasive pad, creating a textured appearance. It provides a more subdued and contemporary look, and is often used in modern architectural designs or furniture. 3. Satin: This finish is similar to brushed, but with a finer texture. It creates a smooth and matte appearance, making it a popular choice for applications that require a sophisticated and elegant look, such as luxury fixtures or appliances. 4. Hammered: This finish involves creating a series of small dents or dimples on the surface of the steel, giving it a textured and rustic appearance. It is commonly used in applications that require a unique and artistic look, such as handrails or decorative accents. 5. Etched: This finish is achieved by chemically treating the steel surface to create a pattern or design. It allows for intricate and detailed designs, making it a popular choice for applications that require personalized or branded elements, such as signage or logos. 6. Powder-coated: This finish involves applying a layer of powdered paint to the steel surface and then baking it to create a durable and vibrant coating. It provides a wide range of color options and is often used in applications that require a decorative and long-lasting finish, such as outdoor furniture or architectural elements. Overall, the choice of steel round bar surface finish depends on the desired aesthetic outcome and the specific requirements of the application. Different finishes can enhance the visual appeal of the steel, making it suitable for various industries and design purposes.

- Q: Is there a steel bar of 6 diameter on the market?

- There is no rebar of 6 diameter on the market.

- Q: Can steel round bars be used for fastener applications?

- Yes, steel round bars can be used for fastener applications. Steel round bars are often used as bolts, screws, and studs in various industries due to their high strength, durability, and resistance to corrosion. They provide a secure and reliable fastening solution for a wide range of applications, including construction, automotive, and machinery.

- Q: Can steel round bars be used in the manufacturing of flanges?

- Yes, steel round bars can be used in the manufacturing of flanges. Flanges are typically used to connect pipes, valves, and other equipment in various industrial applications. While flanges can be made from different materials such as carbon steel, stainless steel, or alloy steel, steel round bars are commonly used due to their strength and durability. The round bars can be machined or forged into the desired flange shape and then further processed to meet specific requirements such as size, thickness, and flange face type. Steel round bars provide excellent mechanical properties and can withstand high pressures, making them suitable for use in flange manufacturing.

- Q: Are steel round bars susceptible to cracking?

- Yes, steel round bars can be susceptible to cracking under certain conditions. Cracking can occur due to factors such as excessive stress, improper handling, or poor manufacturing processes. However, the susceptibility to cracking can be minimized by using high-quality steel, proper heat treatment, and careful handling and installation techniques.

Send your message to us

wholesale Astm 316 /316L Stainless Steel Round Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 24 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords