Stainless Steel Round Bar 316_316L with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Round Bar 316_316L with High Quality

Details of Stainless Steel Round Bar 316_316L with High Quality

Name | Stainless Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

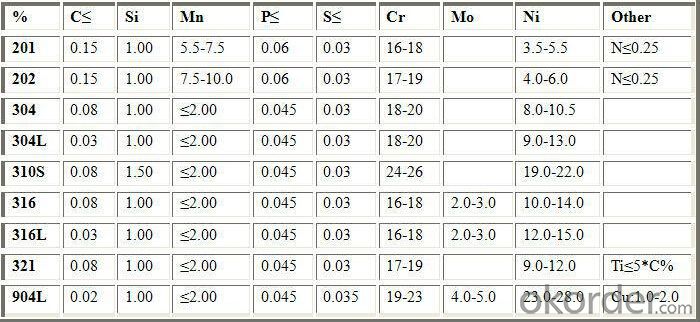

Specification of Stainless Steel Round Bar 316_316L with High Quality

CNBM Introduction of Stainless Steel Round Bar 316_316L with High Quality

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery Stainless Steel Round Bar 316_316L with High Quality

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Are square steel, rectangular tube and angle steel shaped or light steel?

- Light steel is also a relatively vague term, generally can have two kinds of understanding. One is the current "code for design of steel structures" (GBJ 17-88) in the eleventh chapter "bar, small angle light steel structure", refers to the use of steel and light steel structure is less than L45*4 and L56*36*4 angle steel production, mainly in the lack of time for small steel structure manufacturing of reinforced concrete structure should not be used, has been basically not used, so the revised code for design of steel structures has been basically removed this tendency. The other is the "Regulations" technology of steel structure of light-weight buildings with gabled frames with light roof and wall light (also has the condition to use the masonry wall) single portal frame structure, the light here mainly refers to the enclosure is made of light material. Since the former has been cancelled soon, the meaning of "light steel" mainly refers to the latter

- Q: What is the standard length of a steel round bar?

- The standard length of a steel round bar varies depending on the manufacturer and the specific application. However, common standard lengths range from 6 to 12 feet (1.8 to 3.6 meters).

- Q: Can steel round bars be threaded or machined?

- Steel round bars are capable of being threaded or machined. Threading involves the creation of internal or external threads on the surface of a steel round bar, enabling it to connect or fasten to other components. Meanwhile, machining entails the utilization of diverse cutting tools and techniques to eliminate material from the steel round bar, thereby shaping it into the desired form or size. Consequently, both threading and machining can be employed on steel round bars to fulfill specific requirements and applications, including the production of threaded rods, bolts, or customized components.

- Q: Can steel round bars be used for construction purposes?

- Yes, steel round bars can be used for construction purposes. Steel round bars are commonly used in construction for various applications such as reinforcement in concrete structures, as support for beams and columns, and as structural components in bridges, buildings, and infrastructure projects. The high tensile strength and durability of steel make it an ideal choice for construction purposes, as it can withstand heavy loads, provide stability, and ensure the longevity and safety of the structures. Additionally, steel round bars are versatile and can be easily fabricated and customized to meet specific project requirements. Therefore, steel round bars are widely used in the construction industry due to their excellent mechanical properties, reliability, and cost-effectiveness.

- Q: What are the advantages of using niobium-alloy steel round bars?

- There are several advantages to using niobium-alloy steel round bars. Firstly, niobium-alloy steel has excellent strength and toughness properties. The addition of niobium to the steel increases its strength while maintaining its ductility, making it ideal for applications that require high strength and durability. This allows niobium-alloy steel round bars to withstand heavy loads and shocks without deforming or breaking easily. Secondly, niobium-alloy steel has a high resistance to corrosion. This makes it suitable for use in harsh environments where exposure to moisture, chemicals, or corrosive substances is common. The corrosion resistance of niobium-alloy steel ensures that the round bars will remain intact and retain their structural integrity over time, reducing the need for frequent replacements and maintenance. Additionally, niobium-alloy steel has excellent weldability and formability. It can be easily welded and fabricated into various shapes and sizes, making it adaptable to different manufacturing processes and applications. This versatility allows for the production of custom-designed round bars that meet specific project requirements. Moreover, niobium-alloy steel has good heat resistance properties. It can withstand high temperatures without losing its strength or undergoing significant changes in its mechanical properties. This makes it suitable for applications that involve exposure to extreme heat or thermal cycling, such as in the aerospace or automotive industries. Furthermore, niobium-alloy steel is known for its excellent fatigue resistance. It has a high endurance limit, which means it can withstand repeated loading and unloading cycles without experiencing fatigue failure. This makes niobium-alloy steel round bars ideal for applications that involve dynamic or cyclic loading, such as in structural components or machinery. In conclusion, the advantages of using niobium-alloy steel round bars include high strength, corrosion resistance, weldability, formability, heat resistance, and fatigue resistance. These properties make niobium-alloy steel a reliable and cost-effective choice for various industries and applications.

- Q: What is the difference between a seamless and a turned steel round bar?

- The main difference between a seamless and a turned steel round bar lies in their manufacturing process and resulting characteristics. A seamless steel round bar is produced by piercing a solid steel billet, typically through a hot rolling process. This creates a hollow tube-like structure, which is then further elongated and shaped into the desired round bar form. The seamless nature of this bar means that there are no welded joints or seams along its length, resulting in a smooth and continuous surface. This manufacturing method enhances the overall strength and durability of the round bar. On the other hand, a turned steel round bar starts as a solid steel bar, commonly obtained through casting or hot rolling. The bar is then subjected to a machining process known as turning, where it is rotated against a cutting tool to remove material and achieve the desired dimensions and shape. This turning process creates a round bar with a smooth and polished surface. However, unlike a seamless round bar, a turned bar may have mill marks or slight imperfections due to the machining process. In terms of applications, seamless steel round bars are often preferred in industries that require high strength and reliability, such as construction, automotive, and oil and gas. Their uniform structure and absence of welds make them highly resistant to cracking and failure under heavy loads or extreme conditions. Turned steel round bars, on the other hand, are commonly used in applications where a smooth surface finish is desired, such as in decorative pieces or precision components for machinery. Overall, the main difference between a seamless and a turned steel round bar lies in their manufacturing process and resulting characteristics. While both provide a smooth surface finish, seamless round bars offer enhanced strength and reliability due to their seamless structure, whereas turned round bars are often chosen for their precise dimensions and aesthetic qualities.

- Q: What are the advantages of using copper-alloy steel round bars?

- There are several advantages of using copper-alloy steel round bars in various applications. Firstly, copper-alloy steel round bars offer excellent corrosion resistance. The presence of copper in the alloy helps to protect the steel from rust and corrosion, making it suitable for use in environments with high levels of moisture or chemicals. This corrosion resistance extends the lifespan of the round bars, reducing the need for frequent replacements and maintenance. Secondly, copper-alloy steel round bars have high thermal and electrical conductivity. The copper content in the alloy enhances these properties, making them ideal for applications that require efficient heat transfer or electrical conductivity. This makes them suitable for use in electrical components, heat exchangers, and other similar applications. Another advantage of copper-alloy steel round bars is their superior machinability. Copper has excellent machinability properties, which allows for easy cutting, drilling, and shaping of the round bars. This makes them easier to work with and reduces machining time and costs. Additionally, copper-alloy steel round bars offer good strength and toughness. The steel component in the alloy provides the necessary strength to withstand heavy loads and impacts, while the copper component enhances the toughness, making them resistant to cracking or breaking under stress. This makes them suitable for use in structural applications, where high strength and durability are required. Furthermore, copper-alloy steel round bars exhibit good thermal stability. They can withstand high temperatures without losing their mechanical properties, making them suitable for applications that involve exposure to extreme heat or thermal cycling. In conclusion, the advantages of using copper-alloy steel round bars include excellent corrosion resistance, high thermal and electrical conductivity, superior machinability, good strength and toughness, and high thermal stability. These properties make them a preferred choice in various industries, including construction, electrical, automotive, and manufacturing.

- Q: How do you straighten a bent steel round bar?

- To straighten a bent steel round bar, you can follow a few simple steps: 1. Assess the bend: Determine the severity and location of the bend in the round bar. This will help you decide which method to use for straightening. 2. Heat the bar: If the bend is not too severe, you can heat the bar using a blowtorch or a forge. Apply heat evenly across the bent area until it becomes red hot. Heating the bar will make it more malleable and easier to straighten. 3. Apply pressure: Once the bar is heated, you can use a vice or a hydraulic press to apply pressure on the bent section. Gradually increase the pressure until the bar starts to straighten. Be careful not to apply excessive force as it may cause the bar to break. 4. Use leverage: If the bend is not too severe, you can also use leverage to straighten the bar. Secure one end of the bar in a vice or clamp and apply force to the bent section in the opposite direction. Slowly and gently increase the force until the bar straightens. 5. Cold bending: If the bend is minor, you may be able to straighten the bar without applying heat. This method involves using a hammer or mallet to gently tap the bent area in the opposite direction until it straightens. Be cautious not to strike the bar too hard, as it may create new bends or fractures. 6. Check for straightness: After applying the straightening method, carefully inspect the bar to ensure it is straight. If there are any remaining bends, repeat the process until the bar is completely straight. Remember to wear appropriate safety gear, such as gloves and eye protection, when working with steel bars. It is also advisable to consult a professional if you are unsure about the straightening process or if the bar is severely bent.

- Q: How do you measure the length of a steel round bar?

- To measure the length of a steel round bar, you will need a measuring tool called a tape measure or a ruler. First, ensure that the bar is placed on a flat surface. Then, align the zero mark of the tape measure or ruler with one end of the bar. Hold the measuring tool steadily against the bar and extend it along the entire length until you reach the opposite end. Take note of the measurement displayed on the tape measure or ruler at the point where the other end of the bar aligns. This measurement is the length of the steel round bar.

- Q: What are the different grades of steel round bars available?

- Steel round bars are available in various grades, each possessing unique properties and applications. Some commonly used grades include: 1. Mild Steel: This grade is the most affordable and widely used option. It contains a low carbon content, making it easy to weld, cut, and shape. Mild steel round bars are suitable for general construction, fabrication, and manufacturing projects. 2. Carbon Steel: Carbon steel round bars have a higher carbon content compared to mild steel, resulting in greater strength and hardness. They are commonly employed in applications requiring high strength, such as machinery parts, shafts, and axles. 3. Alloy Steel: To improve specific properties, alloying elements like chromium, nickel, manganese, or molybdenum are added to produce alloy steel round bars. These bars offer enhanced strength, toughness, and wear resistance, making them ideal for automotive parts, gears, and tools. 4. Stainless Steel: Stainless steel round bars are corrosion-resistant and possess excellent mechanical properties. They find extensive use in industries like construction, food processing, and medical equipment manufacturing. Different grades of stainless steel, such as 304, 316, or 410, offer varying levels of corrosion resistance and strength. 5. Tool Steel: Tool steel round bars are specifically designed for tool and die production. They exhibit high hardness, wear resistance, and heat resistance. Commonly utilized tool steel grades like D2, A2, or O1 are employed in the manufacture of cutting tools, molds, and dies. Choosing the appropriate grade of steel round bars for your project is crucial and should consider factors such as strength, corrosion resistance, hardness, and machinability. Seeking advice from a steel supplier or an engineer can assist in identifying the most suitable grade for your specific application.

Send your message to us

Stainless Steel Round Bar 316_316L with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords