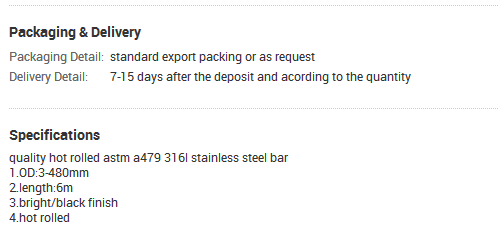

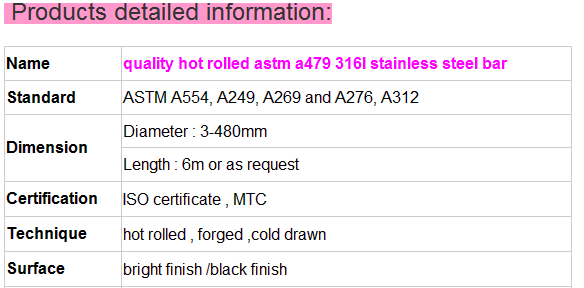

quality hot rolled astm a479 316l stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: What is the difference between Schedule 20 and Schedule 40 stainless steel pipes?

- The main difference between Schedule 20 and Schedule 40 stainless steel pipes lies in their wall thickness and pressure ratings. Schedule 20 stainless steel pipes have a thinner wall thickness compared to Schedule 40 pipes. This means that they have a larger internal diameter, allowing for a higher flow rate of liquids or gases through the pipe. Schedule 20 pipes are commonly used in applications where a lower pressure rating is sufficient, such as residential plumbing or light-duty industrial applications. On the other hand, Schedule 40 stainless steel pipes have a thicker wall thickness than Schedule 20 pipes. This thicker wall provides increased strength and durability, making Schedule 40 pipes suitable for high-pressure applications. They are commonly used in industries like oil and gas, chemical processing, or heavy-duty industrial processes. In terms of pressure ratings, Schedule 20 stainless steel pipes typically have a lower pressure rating compared to Schedule 40 pipes. This is due to the thinner wall thickness of Schedule 20 pipes, which cannot withstand as high pressure as Schedule 40 pipes with their thicker walls. It is important to note that both Schedule 20 and Schedule 40 stainless steel pipes are made from the same material, which is stainless steel. The difference lies solely in their wall thickness and subsequent pressure ratings, making them suitable for different applications based on the required pressure and flow rate.

- Q: What is the external protection used for stainless steel pipes?

- To safeguard stainless steel pipes from corrosion and maintain their integrity, various methods of external protection are employed. One approach involves the application of a protective coating or treatment to shield the pipes and prevent corrosion. Despite stainless steel's inherent resistance to corrosion, it remains vulnerable to certain environmental conditions. A commonly utilized method of external protection entails applying a corrosion-resistant coating, such as epoxy, polyethylene, or zinc. These coatings create a barrier between the stainless steel pipe and its surroundings, preventing direct contact and potential corrosion. Additionally, they serve to safeguard the pipe against physical damage, such as scratches or abrasions, which could lead to corrosion. Another method employed for external protection involves cathodic protection. This technique encompasses either the usage of sacrificial anodes or the application of an electric current to the stainless steel pipe. By sacrificing the anodes or inducing an electrochemical reaction, corrosion is redirected away from the pipe. Furthermore, external protection may include the utilization of insulation materials to prevent condensation and moisture accumulation on the pipe's surface. Moisture can expedite corrosion, and hence proper insulation aids in upholding the stainless steel pipes' integrity. Overall, the aim of external protection for stainless steel pipes is to avert corrosion and ensure their longevity and reliability. By employing various protective coatings, cathodic protection, and insulation, stainless steel pipes can be shielded from environmental factors, thereby guaranteeing optimal performance.

- Q: What's the easiest way to distinguish between stainless steel 202 and 304?

- 304 stainless steel performance is better than 202 stainless steel, the price is more expensive than 202 stainless steel.

- Q: What is the difference between Schedule 30 and Schedule 40 stainless steel pipes?

- Stainless steel pipes are classified into Schedule 30 and Schedule 40 based on their wall thickness and pressure ratings. The primary distinction lies in the wall thickness. Schedule 30 stainless steel pipes possess a slimmer wall in comparison to Schedule 40 pipes. Generally, the wall thickness of Schedule 30 pipes is less than that of Schedule 40 pipes. Consequently, Schedule 30 pipes exhibit a larger internal diameter than Schedule 40 pipes of the same nominal size. The pressure rating and strength of the pipes are directly influenced by the thickness of the pipe walls. Schedule 40 stainless steel pipes are engineered to withstand higher pressure and exhibit greater structural integrity as a result of their thicker walls. They find common usage in industrial settings or for plumbing systems in commercial buildings that involve the transportation of high-pressure fluids or gases. Conversely, Schedule 30 stainless steel pipes are typically employed in applications with lower pressure requirements. They are suitable for situations where more moderate pressure demands exist or where the transported fluid does not necessitate a higher pressure rating. To summarize, the primary disparity between Schedule 30 and Schedule 40 stainless steel pipes resides in their wall thickness. Schedule 40 pipes possess thicker walls and higher pressure ratings compared to Schedule 30 pipes. The choice between the two depends on the specific requirements of the application, including the pressure and nature of the transported fluid.

- Q: Are stainless steel pipes suitable for hot water applications?

- Yes, stainless steel pipes are suitable for hot water applications. Stainless steel is known for its excellent corrosion resistance, which makes it ideal for use in plumbing systems where hot water is involved. The high temperature resistance of stainless steel ensures that it can handle the heat generated by hot water without experiencing any degradation or damage. Additionally, stainless steel pipes have a smooth inner surface, which helps to maintain the quality and purity of the hot water being transported. Overall, stainless steel pipes are a reliable and durable choice for hot water applications.

- Q: Can stainless steel pipes be used in the mining industry?

- Yes, stainless steel pipes can be used in the mining industry. Stainless steel is highly resistant to corrosion, making it suitable for handling various chemicals and minerals found in mining operations. Additionally, its strength and durability make it capable of withstanding the harsh and demanding conditions often encountered in the mining industry.

- Q: What is the difference between seamless and hot-rolled stainless steel pipes?

- Seamless and hot-rolled stainless steel pipes are both commonly used in various industries for their durability and corrosion resistance. However, there are some key differences between the two. 1. Manufacturing process: Seamless stainless steel pipes are manufactured through a process called piercing, where a solid billet is heated and pierced to create a hollow tube. On the other hand, hot-rolled stainless steel pipes are made by heating a solid billet or slab and rolling it into a desired shape. 2. Appearance: Seamless stainless steel pipes have a smooth and uniform appearance due to their manufacturing process. On the contrary, hot-rolled stainless steel pipes have a rough and scaly surface due to the rolling process. 3. Strength: Seamless stainless steel pipes generally have higher strength compared to hot-rolled stainless steel pipes. This is because the seamless pipes undergo additional processes like cold drawing or cold rolling, which enhance their strength. 4. Wall thickness: Seamless stainless steel pipes can have a more precise wall thickness due to their manufacturing process. Hot-rolled stainless steel pipes, on the other hand, may have variations in wall thickness due to the rolling process. 5. Cost: Hot-rolled stainless steel pipes are generally more cost-effective compared to seamless pipes. This is because the manufacturing process of hot-rolled pipes is simpler and requires less time and energy. 6. Availability: Hot-rolled stainless steel pipes are more readily available in the market compared to seamless pipes. This is because the manufacturing process of hot-rolled pipes is faster, allowing for quicker production and availability. In conclusion, while both seamless and hot-rolled stainless steel pipes offer excellent corrosion resistance and durability, they differ in terms of manufacturing process, appearance, strength, wall thickness, cost, and availability. The choice between the two will depend on the specific requirements and preferences of the application or industry in which they will be used.

- Q: Are stainless steel pipes suitable for chemical reactors?

- Yes, stainless steel pipes are suitable for chemical reactors. Stainless steel is a highly durable and corrosion-resistant material, making it ideal for handling various chemicals and corrosive substances. It offers excellent resistance to both high and low temperatures, as well as resistance to oxidation and scaling. Stainless steel pipes can withstand the harsh conditions inside a chemical reactor, including high pressure and aggressive chemicals. Additionally, stainless steel pipes are easy to clean and maintain, ensuring the integrity and longevity of the chemical reactor system. Overall, stainless steel pipes provide a reliable and safe solution for transporting chemicals in chemical reactors.

- Q: What is the standard size range for stainless steel pipes?

- The standard size range for stainless steel pipes varies depending on the industry and application. However, in general, stainless steel pipes are available in a wide range of sizes, starting from small diameters of around 0.5 inches (12.7 mm) to large diameters of up to 48 inches (1219 mm) or even larger in some cases. The wall thickness of stainless steel pipes can also vary, ranging from thin-walled pipes with a thickness of a few millimeters to heavy-walled pipes with thicknesses exceeding an inch. The specific size range for stainless steel pipes may be determined by factors such as the intended use, pressure requirements, and industry standards. It is important to consult relevant specifications and standards to determine the appropriate size range for a specific application.

- Q: Can stainless steel pipes be insulated with silicone?

- Yes, stainless steel pipes can be insulated with silicone. Silicone is a versatile material that can withstand a wide range of temperatures, making it suitable for insulating pipes that carry hot or cold fluids. Silicone insulation is typically available in the form of sleeves or wraps that can be easily applied to the pipe surface. It provides excellent thermal insulation, preventing heat loss or gain from the pipe and improving energy efficiency. Additionally, silicone insulation is resistant to moisture, chemicals, and UV radiation, ensuring long-lasting performance.

Send your message to us

quality hot rolled astm a479 316l stainless steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords