Asbestos Free fiber cement board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Fiber cement board

High Strength

waterproof,fireproof

Mainly used as interior,exterior wall board

High Density and Strength Fiber Cement Board

It is mainly made from cement ,quartz sand and reforcing fiber through the process of slurrying,forming,

high pressure steam curing, drying, surfacing and so on.

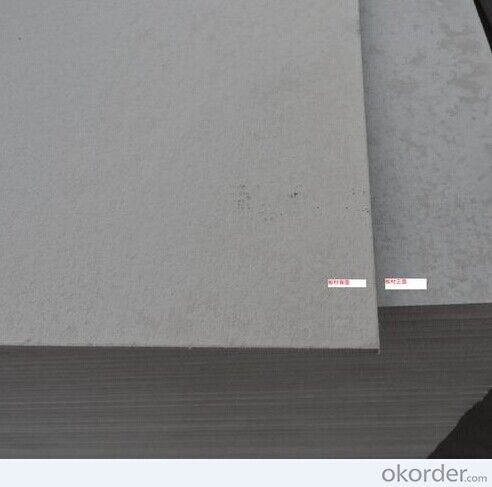

1.Description of fiber cement board

1)Sizes: 1220*2440mm

2)Thickness: 6mm,8mm,10mm,12mm,15mm,18mm or according to customers' request

3)Color: gray, dark gray

4) Packing: pallets and others

2.features of fiber cement board:

1) Incombustibility: It can not burn and give off toxic smoke.

2) Heat insulation: Low heat conductivity, good thermal insulation.

3) Waterproof: It can keep its shape without swelling and deformation after a long time.

4) Sound proof: Reduce indoor noise.

5) Environmental protection: Its special characters make more comfortable environment.

6) High Strength: High-stength and impact-resistant make it is not easy to be damaged.

7) Durability: insulation against bugs, fungus and corrosion,so it can last for a long time.

8) Easy installation: Painting, tiling and nailing can be feasible in the new system.

3.Applications:

Walls

1)Excellent for interior & exterior walls, partitions, curtain walls, fire-stops & more

2)Great substrate for exterior finish materials

3)Abuse resistant

Fiber cement wall panel is a stable performance and light weight building & decoration ceiling,

which takes cement as major and natural fiber reinforced, with the process of pulping, emulsion,

forming, pressurization ,auto claving ,drying and surface treatment.

Product Characteristics:

Fire-proof Rate: Class-A incombustible (GB8624-1997)

Incombustibility (min):240 minutes(GB/T9978-1999)

Density:1.2-1.5g/cm3

Water content ratio: ≤30%

Swelling ratio:≤0.4%

Anti-bending strength:≥16MPa

Frost Resistance: no cracking after 25 cycles of freezing and thawing(GB/T7019-1997)

Radioactivity: standard of BG6566-2001(Class-A Decoration materials)

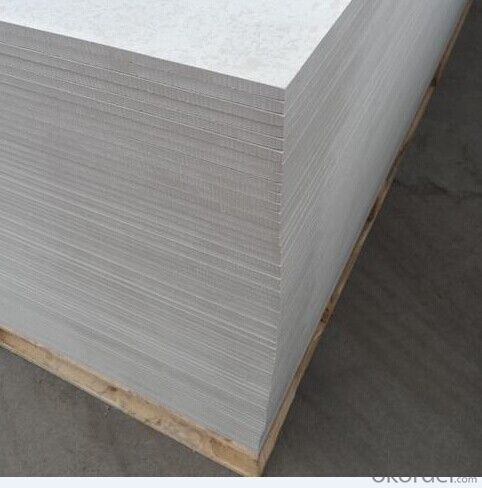

Size & Loading Quantity

Thickness (mm) | Length x width (mm) | PCS/ 20GP | Surface |

5mm | 1200mm x 2400mm 1220mm x 2440mm | 960 PCS /

| Single, double surface Sanding or tapered |

6mm | 1200mm x 2400mm 1220mm x 2440mm | 810 PCS /

| Single, double surface Sanding or tapered |

8mm | 1200mm x 2400mm 1220mm x 2440mm | 600 PCS /

| Single, double surface Sanding or tapered |

9mm | 1200mm x 2400mm 1220mm x 2440mm | 550 PCS /

| Single, double surface Sanding or tapered |

10mm | 1200mm x 2400mm 1220mm x 2440mm | 500 PCS /

| Single, double surface Sanding or tapered |

12mm | 1200mm x 2400mm 1220mm x 2440mm | 410 PCS /

| Single, double surface Sanding or tapered |

15mm | 1200mm x 2400mm 1220mm x 2440mm | 320 PCS /

| Single, double surface Sanding or tapered |

18mm | 1200mm x 2400mm 1220mm x 2440mm | 266 PCS /

| Single, double surface Sanding or tapered |

20mm | 1200mm x 2400mm 1220mm x 2440mm | 240 PCS /

| Single, double surface Sanding or tapered |

Customized sizes and thickness are also produced.

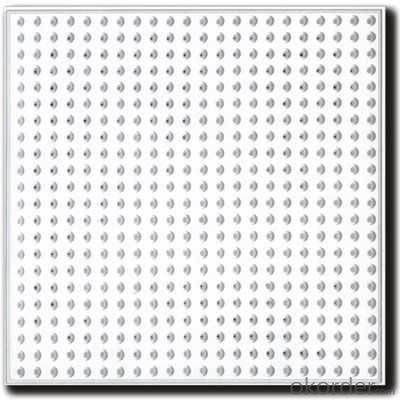

Recommend Application

Partition board , suspended ceilings,exterior wall cladding, paneling ,light weight grouting panel,

interior dry wall decoration board, interior wall after painting and coating.

- Q: What is the actual thickness of all the thickness of the acrylic sheet?

- You buy the actual thickness just fine, you ask how much money enough money. Not OK? You also understand the consumption of their own.

- Q: Now I have to come up with a E1 level test report, but I want to buy E0 level, but the staff of Loulan Ya said that there is no E0 level of this concept. Is this true? Please industry experts to answer the next

- "E0" grade, "E1" grade refers to the formaldehyde emission limit level of environmental standards. "European standard 'E0' class", that is, every 100 grams of plate, formaldehyde emission ≤ 5 mg According to the relevant provisions of the state, furniture, formaldehyde emission to "E2" level can be sold, and by the manufacturing process and other factors, our country basically did not really "E0" class furniture And the world, whether it is composite material or solid wood panels do not exist "zero formaldehyde" sheet metal furniture So that "E0 level" furniture basically does not exist, zero formaldehyde is only legend Can only say that the furniture industry has a small amount of brand of sheet metal furniture, formaldehyde content is far lower than the national standard, is green building materials.

- Q: Are man-made sheets containing formaldehyde?

- Adhesive, with formaldehyde. No aldehyde glue seems not much. How much formaldehyde, and the quality and amount of glue. So buy the floor, pure wood the most environmentally friendly.

- Q: Cabinet cabinet board types which

- Solid wood cabinets. Usually see the most is the cabinet made of solid wood, this cabinet quite popular with consumers, and its advantage is environmental protection, but generally high-grade wood made of the cabinet are more expensive, of course, almost made of solid wood Cabinets are also cheaper. And, in the demand for the purchase of cheap wood do not pay attention to anti-pest control, if you want to post-processing, anti-corrosion paint psoriasis.

- Q: PVC sheet size how much the largest

- The main plate is the width, mainly 1.2 meters and 1.5 meters before the main, and now the widest can reach 2.8 or even 3 meters. As for the length is to see what you need, it is continuous production, according to your request cut.

- Q: Why use office furniture

- Common furniture with the plate varieties are: solid wood, fiberboard, particleboard, blockboard, plywood and so on. At present, the manufacture of office furniture is mainly used are: fiberboard and particleboard. Low-grade office furniture generally use particleboard, and medium and high-grade office furniture generally use fibreboard. Fibreboard is divided into high density fiberboard (density> 0.8 / cm3), medium density fiberboard (0.5 g / cm3 ≤ density ≤ 0.8 g / cc), low density fiberboard (density <0.5 Gram per cubic centimeter). High density fiberboard due to high density, difficult processing, and easy to nail, the installation of accessories burst; and low density fiberboard due to low density, large gap between wood fibers, easy to water swelling, resulting in surface cladding off, and even the plate disintegration, so the second The use of office furniture are less. The MDF (medium MDF), with the surface smooth, the internal structure of fine, good processing effect, with strong resistance to deformation and load-bearing capacity, And the plate holding nail ability, can be achieved many times disassembly, as in the high-end office furniture of choice. Sunlong's office furniture is used in the manufacturer's custom-made density of up to 0.76 grams per cubic centimeter of the MDF (generally medium density fiberboard density of 0.64 grams per cubic centimeter or so).

- Q: Which furniture plates are suitable for painting and stamping panels? Thank you

- Nine PCT board, because he has lines can also be sprayed, out of the effect is very good

- Q: 601 grades of stainless steel, would like to know its chemical composition and use, thank you!

- 601 stainless steel Product Name: 【nickel-based alloy】 Product Origin: Japan Metallurgical / SMC / VDM / ATI Product Brand: Germany ThyssenKrupp VDM US Hastelloy Japan Metallurgical OUTOKUMPU (Otto Kunpu) US Metallurgical ATI Specifications: Forging, bar, sheet, strip, ring, wire, flange, etc. can be produced according to customer requirements Application: widely used in aerospace, electricity, petrochemical, shipbuilding, machinery, electronics, environmental protection and other industries.

- Q: Home to decorate, and ready to ask the carpenter to play furniture, but do not know what plate on the plate is good, small pollution and moisture effect is good, but also ask the bathroom cabinet if you buy plate to play what plate is good? Please have experienced friends to give me guidance, thank you!

- Daxing board is decorated with the Secretary for more, more suitable for hand to do, its quality also has several levels, it is characterized by a good grip screw, high strength, with a strong quality, sound absorption, insulation and other characteristics, And the water content is not high, between 10% -13%, processing is simple, the most widely used. But afraid of wet, construction should be avoided to avoid use in the kitchen. The most suitable for use in furniture, doors and windows and sets, partition, false walls, heating hood, curtains and so on High-density board to be hard is a thin fiber, not suitable for hand, suitable for machine processing, do the wardrobe or more appropriate, as the variant. If it is called woodworking is a big core board is good.

Send your message to us

Asbestos Free fiber cement board

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords