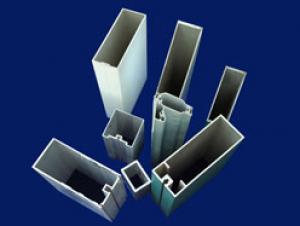

Architectural Aluminum Profiles - Aluminum Product Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALUMINUM PRODUCT ALUMINUM PROFILES

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: How is the aluminum alloy profile series divided?

- According to alloy composition.1 pure aluminum, such as 1100,2 series aluminum alloy3 Series al Mn alloys, such as 3003, 3A214 series Al Si alloy5 Series Al Mg alloy6 series Al Mg Si alloy, such as 606360617 Series Al Zn Alloy8 lines, others9 line standby

- Q: Is there any health risk linked to the use of aluminum profiles in construction?

- <p>There are minimal health risks associated with using aluminum profiles in construction. Aluminum is a non-toxic metal and does not emit harmful substances. However, during the manufacturing process, if not properly controlled, there might be exposure to dust or fumes which could be harmful if inhaled. Additionally, aluminum dust can cause skin irritation. It's important to handle aluminum profiles with care and use appropriate safety measures, such as wearing masks and gloves, to minimize any potential health risks.</p>

- Q: How do you calculate the weight-bearing capacity of aluminum profiles?

- To calculate the weight-bearing capacity of aluminum profiles, you need to consider various factors such as the dimensions of the profile, the material grade of aluminum used, and the specific application requirements. Firstly, determine the dimensions of the aluminum profile, including the length, width, and thickness. These measurements will help you calculate the cross-sectional area of the profile, which is a crucial parameter in determining its load-bearing capacity. Next, consider the material grade of aluminum used in the profile. Aluminum alloys have different strength properties, so it is essential to know the specific alloy and temper designation. This information can be obtained from the manufacturer or supplier. Once you have the cross-sectional area and material grade, you can refer to engineering standards or handbooks that provide load tables or formulas for calculating the safe load capacity of aluminum profiles. These resources usually provide a range of load ratings based on different loading conditions, such as static or dynamic loads, and factors like span length, support conditions, and safety factors. It is crucial to consider the specific application requirements and any additional factors that may affect the load-bearing capacity, such as temperature, vibration, or potential impact forces. These factors may require further adjustments to the calculated load capacity. Additionally, consulting with a structural engineer or an aluminum profile manufacturer can provide valuable insights and recommendations for calculating the weight-bearing capacity more accurately. They may have specialized knowledge or testing data specific to the aluminum profile in question, ensuring a more reliable calculation. Overall, calculating the weight-bearing capacity of aluminum profiles involves considering the dimensions, material grade, specific application requirements, and consulting relevant resources or experts in the field to ensure accurate and safe load calculations.

- Q: This question asks for a list of various interior wall cladding systems that incorporate aluminum profiles.

- <p>Aluminum profiles are versatile and commonly used in interior wall cladding systems due to their durability and aesthetic appeal. Some of the different types include: 1. Aluminum Composite Panels (ACP), which combine two aluminum sheets with a non-aluminum core. 2. Aluminum Insulated Panels, offering thermal insulation properties. 3. Aluminum Curtain Wall Systems, providing a weather-resistant exterior wall. 4. Aluminum Lining Systems, used for decorative purposes and easy maintenance. 5. Aluminum Ceiling Systems, which can also serve as wall cladding in some designs. 6. Aluminum Drywall Systems, which are lightweight and easy to install. Each system has its specific applications and advantages, making aluminum profiles a popular choice in modern architecture and interior design.</p>

- Q: Inquire if aluminum profiles can be recycled locally or regionally and how to find more information about it.

- <p>Yes, aluminum profiles can be recycled both locally and regionally. Recycling aluminum is an efficient process that conserves resources and energy. To find out more about local recycling options for aluminum profiles, you can: 1) Contact your local waste management or recycling center to inquire about their services. 2) Search online for recycling facilities in your region that specialize in aluminum. 3) Reach out to local metal scrapyards, as they often accept aluminum for recycling. 4) Check with local environmental agencies or non-profit organizations focused on recycling for guidance and resources.</p>

- Q: What are the different machining techniques for aluminum profiles?

- For aluminum profiles, there are various machining techniques available depending on the desired result and project specifications. Some commonly used techniques include: 1. Milling: Rotary cutters are used to remove material from the aluminum profile, allowing for the creation of intricate shapes, slots, and holes. This can be done manually or with the assistance of computer numerical control (CNC) milling machines. 2. Drilling: By employing a rotating cutting tool called a drill bit, holes of different sizes and shapes can be made in the aluminum profile. 3. Turning: A stationary cutting tool is utilized while the aluminum profile rotates, resulting in the removal of material and the creation of cylindrical shapes like shafts or rods. 4. Bending: To achieve curved or angled shapes, the aluminum profile is deformed using this technique. It is widely employed in industries such as construction and automotive. 5. Grinding: By applying abrasive particles to the surface of the aluminum profile, material is eliminated and a smooth finish is achieved. This technique is frequently utilized for precise dimensions and high-quality surface finishes. 6. Sawing: The aluminum profile is cut to the desired length or specific shapes using a saw blade. 7. Welding: The edges of two or more aluminum profiles are melted and fused together to form strong and durable joints. This technique is commonly employed in industries like construction and aerospace. These are just a few examples of the numerous machining techniques available for aluminum profiles. The selection of a technique depends on factors such as the desired outcome, design complexity, and project requirements.

- Q: How are the tonnage grades of aluminum extrusion machines classified?

- Aluminum Alloy stamping metal iron because material is relatively soft, expensive, easy to break and some Aluminum Alloy products also need subsequent processing, such as drawing, anode processing, especially in stamping production to produce top injuries, scratches, in the mold manufacturing should pay special attention to the following:1, for the project does not affect the number of cases, punching as far as possible behind the project, punching, and even for punching a large number of products, may consider more than one project, but also the punching line in the back.2, aluminum material is soft, and the mold is easy to block material, so in the design of mold gap should be put bilateral material thickness of 10% gap, the knife edge straight depth to 2MM is more appropriate, the taper to 0.8-1 degrees is appropriate.3, bending forming, because aluminum material in bending when easy to produce aluminum chip, will cause spot injury, indentation, aluminum raw material needs to stick PE film, in the roller and electroplating case, forming block with polishing hard chromium is better.4, the need for anode processing after stamping, such as pressing and flattening process of 180 degrees, the product can not be completely pressed, completely pressed will spit acid phenomenon for 0.2-0.3MM seam, acid to timely outflow, so we must do this step on the limiting block and calibration mode is higher than the norm out on.5, because the aluminum material is crisp, easy to crack, especially in the case of anti flanging, so try not to do the line, even if you want to do, but also to make the line width a little bit, a little lighter.6, all aluminum blade are required to use wire cut, to prevent the burrs and blanking is not smooth, easy to produce high temperature aluminum, so the punch hardness requirements of more than 60 degrees, at least with SKD11 material, has no D2 arithmetic matter punch.

- Q: Is it possible to utilize aluminum profiles as a component in systems designed for covering interior walls?

- <p>Yes, aluminum profiles can be used for interior wall cladding systems. They are lightweight, durable, and resistant to corrosion, making them an ideal choice for both residential and commercial applications. Aluminum profiles are easy to install and can be used in conjunction with various materials such as glass, stone, or wood to create a sleek and modern look. They are also customizable, allowing for a wide range of design options and can be powder-coated or anodized for different finishes and colors to match any interior design scheme.</p>

- Q: This question asks for a comparison between aluminum profiles and other building materials regarding their cost and performance.

- <p>Aluminum profiles are often more cost-effective than materials like steel or wood in the long run due to their durability and low maintenance requirements. They offer high strength-to-weight ratios, making them ideal for structures where weight is a concern. Additionally, aluminum profiles have excellent resistance to corrosion and weathering, which reduces the need for repainting or replacement over time. They are also energy-efficient, as they can help in reducing heat transfer, thus lowering energy costs for heating and cooling. However, the initial cost of aluminum profiles can be higher than some alternatives, but their long-term performance and low maintenance can offset this initial expense.</p>

- Q: This question asks about the impact of aluminum profiles on the thermal efficiency of a building.

- <p>Aluminum profiles can significantly affect the thermal performance of a building. They are excellent conductors of heat, which means they can transfer heat quickly. This property can be both advantageous and disadvantageous. On the positive side, aluminum profiles can help dissipate heat from the building, reducing the need for air conditioning. However, they can also lead to heat loss in colder climates, reducing the building's energy efficiency. To mitigate this, thermal breaks are often incorporated into aluminum profiles to reduce heat transfer. Additionally, insulating materials can be used alongside aluminum profiles to enhance the building's thermal insulation. Proper design and material selection are crucial to optimize the thermal performance of a building with aluminum profiles.</p>

Send your message to us

Architectural Aluminum Profiles - Aluminum Product Aluminum Profiles

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords