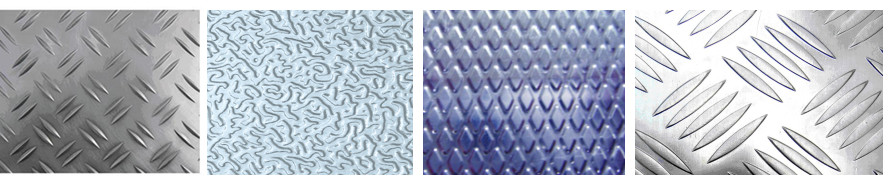

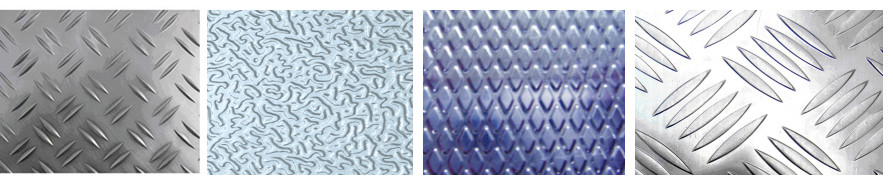

Anti Slippery Aluminum Galvanized Sheets Cleveland

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Textured Aluminum Sheet Tread Plate , Five Bars Embossed Aluminum Sheet

Aluminum Plate, Aluminum Sheet, Aluminum Roll, Aluminum Coil, Aluminum Alloy

Product | Textured Aluminum Sheet Tread Plate , Five Bars Embossed Aluminum Sheet

|

Material | 3003(3000 series) |

Status | H14 |

Thickness | 0.5-2.0mm |

Aluminum content | ≥ 95.00% |

Surface | mill finish,no scratching,without burrs |

Property | good extensility,anti-corrosion,good welding performance |

Technical standard | GB/T3880-2006 |

Brand name | CNBM |

Division | Alloy | Application | Feature |

1000 SERIES | 1050 1060 1070 1200 | Utensil, decoration, Reflecting plate, Printing plate, heatproof plate | -Easy to process and weld, resistant to rust, High conductibility of electricity and heat, low strength -Kinds of Cookware |

3000 SERIES | 3003 3005 3105 | Utensil (F/P, inside of rice cooker), aluminum can, material for interior and exterior of building, Celluar Phone | -A3003 : Anodizing Cookwares, general wares, frying pan, coating, Pressure cooker, electric rice cooker, Utensil, Mobile Phone cover & Battery Case Cheaper item with standard quality |

5000 SERIES | 5083 5052 5754 5A05 | Ship board heatproof apparatus, material for interior and exterior of building, Parts of Electronic tools Automobile Components: | Easy to process and weld and superior hardness &heatproof |

6000 SERIES | 6061 6063 | IT equipment & facility, Mould material, motor material, automatic line, machine & plant etc. | -Easy to process , resistant to rust, superior surface treatment |

8000 SERIES | 8011 | Kitchen utensils, Bottle cap | -8000 series is durable to process with special alloy. |

- Q: Can 101 aluminum sheets be used in the production of decorative panels?

- Yes, 101 aluminum sheets can be used in the production of decorative panels.

- Q: Can aluminum sheets be used for electrical wiring?

- No, aluminum sheets cannot be used for electrical wiring. While aluminum is a good conductor of electricity, it is not suitable for electrical wiring due to its high electrical resistance. Copper is the preferred material for electrical wiring as it has low resistance and is more efficient in conducting electricity. Additionally, aluminum is prone to oxidation, which can lead to poor conductivity and potential fire hazards. Copper wires are specifically designed and manufactured to meet the electrical safety standards, ensuring reliable and safe electrical connections.

- Q: Can aluminum plate resist acid and alkali?

- The metal oxide film changes the surface state and properties, such as surface coloring, corrosion resistance, abrasion resistance and hardness, and metal surface protection. For example, aluminum anodizing, the aluminum alloy placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, under certain conditions and applied electricity under the electrolysis. Anodized aluminum or its alloy, formed on the surface of alumina thin layer, its thickness is 5~20 microns, anodized aluminum or its alloy. Therefore, the surface hardness and wear resistance of the aluminum alloy were greatly improved by the treatment process.Shanghai Ai Li AI metal materials, dedicated to serve you.

- Q: Are aluminum sheets suitable for interior design applications?

- Yes, aluminum sheets are suitable for interior design applications. Aluminum is a versatile and durable material that can be used in various ways to enhance the aesthetics of interior spaces. It can be easily shaped, cut, and manipulated to create unique and modern designs. Aluminum sheets are available in different finishes, such as brushed, polished, or textured, which allows for a wide range of design possibilities. One of the main advantages of using aluminum sheets in interior design is their lightweight nature. This makes them easy to handle and install, reducing labor and transportation costs. Additionally, aluminum is resistant to corrosion, making it suitable for areas with high humidity or moisture, such as bathrooms or kitchens. Aluminum sheets can be used for various applications in interior design, including wall cladding, ceiling panels, room dividers, furniture, and decorative elements. They can be painted or coated in different colors to match any interior design scheme. Aluminum sheets can also be perforated or engraved to create patterns or intricate designs, adding a unique visual appeal to the space. Furthermore, aluminum is a sustainable material as it is highly recyclable. Its recycling process requires only a fraction of the energy needed to produce new aluminum, making it an eco-friendly choice for interior design applications. In conclusion, aluminum sheets are highly suitable for interior design applications due to their versatility, durability, lightweight nature, resistance to corrosion, and ability to be shaped and manipulated. They offer a wide range of design possibilities and can be used for various applications, making them a popular choice among designers and architects.

- Q: Can aluminum sheets be anodized for corrosion protection?

- Aluminum sheets have the capacity to undergo anodization in order to safeguard against corrosion. Anodizing initiates an electrochemical reaction that generates a safeguarding oxide layer on the aluminum's surface. This protective oxide layer exhibits exceptional resistance against corrosion and provides a robust and enduring shield. Various aluminum products, including sheets, can be subjected to anodizing to elevate their resistance against corrosion, enhance their aesthetic appeal, and prolong their lifespan. The anodizing process entails immersing the aluminum sheet in an electrolyte solution and applying an electric current, enabling oxygen ions to bond with the metal's surface and establish the safeguarding oxide layer. Anodized aluminum sheets are extensively employed in vital industries such as aerospace, automotive, construction, and electronics, where corrosion resistance is of paramount importance.

- Q: What are the different surface finishes available for aluminum sheets?

- Aluminum sheets offer a variety of surface finishes, each with its own unique qualities and aesthetic appeal. Some commonly used finishes include: 1. Mill Finish: This is the most basic finish achieved by leaving the aluminum in its as-rolled state, without any further treatment. It has a smooth and shiny appearance, but may have slight imperfections and is not as durable as other finishes. 2. Anodized Finish: Anodizing is an electrochemical process that creates a protective layer on the surface of the aluminum sheet. This finish enhances corrosion resistance, improves durability, and offers a wide range of color options. Anodized finishes can be matte or glossy. 3. Brushed Finish: By brushing the aluminum sheet with a fine abrasive material, a textured pattern is created. This finish is commonly used for decorative purposes and provides a unique and attractive appearance. 4. Polished Finish: Polishing the aluminum sheet using abrasive materials creates a smooth and reflective surface. This finish is often used for decorative purposes, giving the aluminum a high-end, mirror-like appearance. 5. Embossed Finish: Embossing involves creating raised or recessed patterns on the surface of the aluminum sheet. This finish is commonly used for decorative purposes, adding texture and visual interest to the material. 6. Powder Coated Finish: Powder coating entails applying a dry powder to the aluminum sheet and curing it under heat. This finish provides a durable and weather-resistant coating, available in a wide range of colors and textures. 7. Patterned Finish: Patterned finishes are achieved by imprinting various designs or patterns onto the surface of the aluminum sheet. This finish is often used in architectural applications, adding visual interest to the material. These examples demonstrate the range of surface finishes available for aluminum sheets. The choice of finish depends on the desired appearance, functionality, and application requirements.

- Q: Aluminum standard 30*25*2500 to 1000 1 how to calculate the number of materials needed?. 2 how to calculate the cutting loss?

- How many density units should be used in international units per kilogram of cubic meters, so that the unit of mass is kilogram? Weight = quality *9.81. The unit of cattle per kilogram is 5.4 kg of pure aluminum, and the weight is about 53 cows

- Q: What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically refers to the alloy used in their manufacturing. Aluminum alloy 101 is a commercially pure aluminum with a minimum of 99.0% aluminum content. It does not contain any significant amounts of other elements, making it the most basic and pure form of aluminum available. This high purity level makes it highly resistant to corrosion and provides excellent electrical conductivity. 101 aluminum sheets are often used in applications where a high degree of electrical conductivity or corrosion resistance is required, such as in electrical wiring, heat exchangers, and chemical processing equipment.

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: Are aluminum sheets recyclable?

- Yes, aluminum sheets are recyclable. Aluminum is a highly recyclable material, and the recycling process for aluminum sheets is relatively simple and efficient. Recycling aluminum sheets involves melting the metal down and reforming it into new sheets or other aluminum products. The recycling process for aluminum requires considerably less energy compared to the production of new aluminum, making it an environmentally-friendly option. Additionally, recycling aluminum sheets helps conserve natural resources and reduces the amount of waste sent to landfills. Therefore, it is encouraged to recycle aluminum sheets whenever possible to contribute to a more sustainable and eco-friendly future.

Send your message to us

Anti Slippery Aluminum Galvanized Sheets Cleveland

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords