Aluminum Galvanized Sheets with Best Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

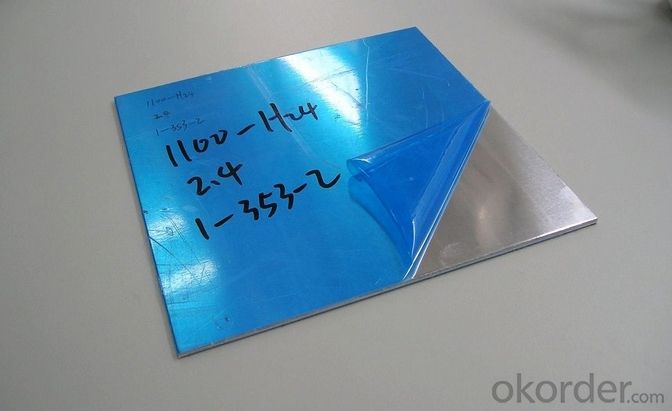

1.Structure of Product Description

hot rolled and cold drawn and cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series,5000 series,7000series, 8000 series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1220mm*2440mm,1219mm*2438mm,1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 5 tons/each size.

How many tons did you export in one year?

---Normally it is around 9000 tons totally.

Where is your client from?

---Normally it is from UAE, Saudi Arabia, England,Turkey,Japan, etc.

What is your mainly products?

---Normally they are aluminum sheet,big-5-bar aluminium checkered sheet,small-5-bar aluminium checkered sheet,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q: Which explains aluminum's resistance to corrosion? Any aluminum oxide that forms readily falls off the metal and exposes the corrosion-resistant metal. The aluminum oxide that forms adheres to the metal surface. The reduction half-reaction Al3+(aq) + 3e- ---gt; Al(s) occurs readily. The standard reduction potential for the Al3+/Al half-reaction is above the standard reduction potential for the O2/H2O half-reaction.

- i would start by plugging in some of those key terms into wikipedia. it often has shockingly good engineering physics articles. there are really only 4 variables: exhaust tube, annealing furnace, age hardened aluminum alloy. play with those, and you might find terms that lead you to your answer

- Q: How do aluminum sheets perform in terms of flexural strength?

- Aluminum sheets generally exhibit excellent flexural strength properties. Due to their inherent structural integrity and high strength-to-weight ratio, aluminum sheets are capable of withstanding bending forces without significant deformation or failure. The flexural strength of aluminum sheets can vary depending on the alloy and temper selected, as well as the thickness of the sheet. However, in general, aluminum sheets are known to exhibit good resistance to bending and can withstand applied loads without buckling or breaking. This makes aluminum sheets suitable for various applications that require components to withstand flexural stresses, such as in the construction, automotive, aerospace, and marine industries. Additionally, aluminum sheets can be further enhanced through various fabrication techniques and alloying elements to optimize their flexural strength for specific applications.

- Q: Wonderland is the hard aluminum with what tools do? Thank you

- Wrought iron platform made 3 aluminum alloy with a hard aluminumAluminum + granite can also be synthesized

- Q: Can aluminum sheets be used as a substitute for steel in certain applications?

- Certain applications can utilize aluminum sheets as a replacement for steel. Aluminum, a versatile and lightweight material, offers numerous advantages over steel. Its high strength-to-weight ratio allows it to deliver comparable strength while being considerably lighter. This quality makes aluminum sheets an outstanding option for weight-sensitive applications, like those in the aerospace, automotive, and transportation industries. Furthermore, aluminum boasts exceptional corrosion resistance, negating the necessity for supplementary protective coatings or treatments. Consequently, aluminum sheets are suitable for employment in marine environments or other corrosive settings. Additionally, aluminum sheets possess remarkable thermal conductivity, making them ideal for applications that necessitate heat dissipation, such as heat exchangers or radiators. Moreover, aluminum is more pliable than steel, facilitating easier shaping and forming. This attribute renders aluminum sheets suitable for applications that require intricate or complex designs. However, it is vital to acknowledge that aluminum has lower tensile strength in comparison to steel. Consequently, in applications demanding substantial load-bearing capacities or structural integrity, steel may remain the preferred choice. In such instances, a thorough evaluation of specific requirements and trade-offs between weight, strength, and cost should be conducted before opting to use aluminum sheets as a steel substitute.

- Q: Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has excellent thermal conductivity, meaning it can efficiently conduct and transfer heat away from the source. Additionally, aluminum has a high melting point, allowing it to withstand high temperatures without warping or deforming. These properties make aluminum sheets an ideal choice for heat shield applications, such as protecting sensitive components or structures from heat damage in various industries including automotive, aerospace, and industrial applications. Furthermore, aluminum is lightweight and relatively easy to shape, making it a practical choice for heat shields that need to be installed in tight spaces or require complex designs. Overall, the use of aluminum sheets as heat shields offers effective thermal protection while providing durability, versatility, and cost-effectiveness.

- Q: on the metal activity series, aluminum sits between magnesium and zinc, and all three sit above hydrogen. Explain why aluminum typically reacts only slowly with dilute acids even though both magnesium and zinc react rapidly

- Aluminum metal reacts with oxygen in the air to form a very tightly bonded aluminum oxide on its surface which slows the attack of acids trying to make contact with the aluminum atoms below the surface.

- Q: What are aluminum sheets?

- Aluminum sheets are thin, flat pieces of aluminum that are commonly used in various industries and applications. They are made from aluminum, which is a lightweight and versatile metal known for its exceptional strength, durability, and corrosion resistance. These sheets can range in thickness, width, and length, depending on the specific requirements of the project. Aluminum sheets are widely used in construction, automotive, aerospace, packaging, and manufacturing industries, among others. They are used for a multitude of purposes such as roofing, cladding, signage, transportation, electrical enclosures, and even household utensils. The flexibility and malleability of aluminum allow for easy shaping and forming, making it a popular choice for a wide range of applications. Additionally, aluminum sheets can be coated or finished to further enhance their appearance or protect them from external factors such as moisture, UV rays, or chemicals. Overall, aluminum sheets are essential materials that offer a combination of lightweight, strength, and corrosion resistance, making them ideal for various industrial and commercial uses.

- Q: Is aluminum sheet magnetic?

- Incorrect, aluminum sheets lack magnetic properties. As a non-magnetic metal, aluminum neither attracts nor repels magnetic materials due to the absence of magnetic elements within its composition. Consequently, attempting to affix a magnet onto an aluminum sheet will prove futile, as it remains unaffected by magnetic fields.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- The stadium opened in 1970, so that would be aluminum.

Send your message to us

Aluminum Galvanized Sheets with Best Price in Our Warehouse

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords