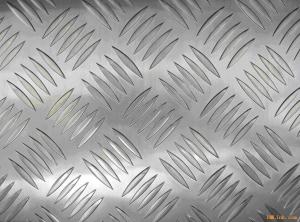

500 Sheets of Aluminum Foil 9 In - Aluminium Two Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum sheet / plate

1) Alloy: 1050. 1060, 1100, 1070, 1200, 3003 5052 5754 5083 5086 6061 6061 7075

2) Temper: soft, 1/4 hard, 1/2 hard, hard, H12, H14

3) Thickness: 0.2mm to 300mm

4) Width: 100mm to 2300mm, Length: up to 2300mm,

5) Main application: Tray, Road traffic signs, Car license, Automotive body, Wall decoration,

Auto radiator, Food container, Aluminum ceiling, Battery shell, LED Lighting, Kitchen rinse bath,

lamp shade , heat exchanger, nameplate, Power transformer, pallet etc.

CHEMICAL COMPOSITION

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

1060 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.6 | ||

1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.5 | ||

1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 99.0 | |||||

1200 | 1.0 | 0.05 | 0.05 | 0.1 | 0.05 | 99.0 | ||||

3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | 0.1 | remainder | ||||

Product Information

Aluminum sheet is usually according to the following two points:

1. According to the alloy composition is divided into:

High purity aluminum plate rolling (by the content above 99.9 high purity aluminum)

Pure aluminum plate (ingredients made from pure aluminum rolling)

Alloy aluminum plate (composed of aluminum alloy and auxiliary, usually with aluminum and copper, aluminum and manganese, aluminum and silicon, aluminum magnesium, etc)

Composite aluminum plate or brazing plate (through a variety of means of material compound special use aluminum material)

Outside package aluminum (aluminum coated aluminum sheet used for special purposes)

2. According to the thickness is divided into: (mm)

Sheet (aluminum sheet) 0.15 to 2.0

Conventional plate (aluminum sheet) 2.0 to 6.0

Medium plate (aluminum plate), 6.0 to 25.0

Plate (aluminum plate) 25-200

Super thick plate more than 200

- Q: Can aluminum plate resist acid and alkali?

- The metal oxide film changes the surface state and properties, such as surface coloring, corrosion resistance, abrasion resistance and hardness, and metal surface protection. For example, aluminum anodizing, the aluminum alloy placed in the corresponding electrolyte (such as sulfuric acid, chromic acid, oxalic acid, etc.) as an anode, under certain conditions and applied electricity under the electrolysis. Anodized aluminum or its alloy, formed on the surface of alumina thin layer, its thickness is 5~20 microns, anodized aluminum or its alloy. Therefore, the surface hardness and wear resistance of the aluminum alloy were greatly improved by the treatment process.Shanghai Ai Li AI metal materials, dedicated to serve you.

- Q: Can the aluminum sheets be used for insulation purposes?

- Yes, aluminum sheets can be used for insulation purposes. Aluminum is a good conductor of heat, so it can effectively reflect and block the transfer of heat. Additionally, aluminum sheets are lightweight and durable, making them suitable for insulation applications in various industries such as construction, automotive, and aerospace.

- Q: What are the different alloy compositions available for aluminum sheets?

- Aluminum sheets offer a variety of alloy compositions, each with its own distinct properties and applications. There are several common alloy compositions to consider. Firstly, we have 1100, which stands out for its exceptional corrosion resistance and high thermal conductivity. This alloy finds its place in chemical equipment, heat exchangers, and food processing equipment. Next, 3003 presents good formability, moderate strength, and excellent corrosion resistance. It is commonly employed in packaging, tanks, and architectural applications. Moving on to 5052, this alloy boasts high strength and good formability. It is often utilized in marine applications, as well as in aircraft and automotive parts. For those seeking excellent strength, good formability, and high corrosion resistance, 6061 is the alloy of choice. It is commonly found in structural applications like bridges, buildings, and transportation equipment. Lastly, we have 7075, known for its remarkably high strength and good machinability. Aerospace applications, as well as high-stress parts in the automotive and sporting goods industries, benefit from this alloy. These examples merely scratch the surface of the numerous alloy compositions available for aluminum sheets. The selection of the appropriate alloy hinges on specific application requirements, such as strength, corrosion resistance, formability, and machinability.

- Q: This question asks for the various types of surface treatments or coatings that can be applied to aluminum profiles to enhance their properties or appearance.

- <p>Aluminum profiles can be coated with several types of finishes to improve their aesthetic appeal, durability, and corrosion resistance. The common types include: 1) Anodizing, which creates a protective oxide layer on the aluminum surface; 2) Powder coating, where a dry powder is electrostatically applied and then cured under heat; 3) Electrophoretic coating, a method where charged particles adhere to the aluminum and then harden; 4) PVDF (Polyvinylidene Fluoride) coating, known for its excellent weather resistance and durability; 5) Thermal spraying, where a coating material is melted and sprayed onto the aluminum surface; and 6) Painting, which can be done through various methods such as airless spray or dip coating. Each type of coating serves different purposes and has its own set of advantages and applications.</p>

- Q: Is it suitable to use aluminum sheets as roofing materials in areas with high temperatures?

- <p>Yes, aluminum sheets can be used for roofing materials in hot climates. Aluminum has a high thermal conductivity, which means it can quickly dissipate heat, helping to keep buildings cooler. It also has excellent resistance to corrosion, which is beneficial in areas with high humidity or salt air. Additionally, aluminum is lightweight, easy to install, and can be recycled, making it an environmentally friendly option. However, it's important to ensure proper ventilation and insulation to maximize its performance in hot climates.</p>

- Q: Can aluminum sheets be used for signage purposes?

- Yes, aluminum sheets can be used for signage purposes. They are commonly chosen for outdoor signs due to their durability, weather resistance, and lightweight nature. Aluminum sheets can be easily customized, printed on, and shaped to create professional and long-lasting signage.

- Q: This question asks about the energy savings achieved by using aluminum sheets in comparison to other materials.

- <p>The energy savings achieved by using aluminum sheets instead of other materials can be significant. Aluminum is lightweight and has excellent thermal conductivity, which means it can reduce energy consumption in applications like building insulation and heat exchangers. For instance, aluminum-framed buildings can save up to 40% more energy than those made with traditional materials due to better insulation properties. Additionally, in industrial processes, aluminum's high thermal conductivity can lead to energy savings of around 33% compared to using copper in heat exchangers. The exact amount of energy saved depends on the specific application and the materials being replaced.</p>

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, aluminum sheets can be used for green building materials. They are lightweight, durable, and have high recyclability, which reduces waste. Aluminum is also energy-efficient in production and use, and its reflective properties can help in reducing heat absorption, thus lowering cooling costs. Additionally, aluminum's resistance to corrosion and weathering means it requires less maintenance, contributing to its sustainability in green building practices.</p>

- Q: answer them please! i need help. the main question is # 1!!! 2. how many atoms are in one particle of aluminum dichromate?3. how many phosphorus atoms are in one particle of calcium phosphate?4. how many total atoms are in one particle of calcium phosphate?PLEASE!! who ever answers all, ill give them best answer a 5 star ratinggg. please!!! THANK YOU!

- 1) Look at the formula for aluminum nitrate [Al(NO3)3]. The subscript of 3 outside of the parentheses means that you multiply each atom inside the parentheses by 3. Since there is only one nitrogen inside the parentheses, this means that you multiply that by 3. There are a total of 3 nitrogen atoms in each molecule of aluminum nitrate. 2) The formula for aluminum dichromate is Al2(Cr2O7)3. Again, multiply each atom in the parentheses by 3, add them, then add 2 to that number for the aluminum. That's your answer. 3) The formula for calcium phosphate is Ca3(PO4)2. Multiply P by 2. 4) Follow the same steps as in #2, above.

- Q: How do you determine the thickness tolerance of an aluminum sheet?

- To determine the thickness tolerance of an aluminum sheet, several factors need to be considered. Firstly, it is important to refer to the industry standards and specifications for aluminum sheets. These standards typically provide guidelines and tolerances for various thicknesses of aluminum sheets, which can vary depending on the specific alloy and grade of the material. Next, it is crucial to use precise measuring equipment such as calipers or micrometers to accurately measure the thickness of the aluminum sheet. Multiple measurements should be taken at different locations on the sheet to account for any potential variations. Once the measurements are obtained, they should be compared to the specified thickness tolerance provided by the industry standards. The tolerance typically represents the acceptable range within which the actual thickness of the sheet can vary. For instance, if the specified thickness tolerance is ±0.002 inches, it means that the sheet's thickness can vary within this range. If the measured thickness falls within the specified tolerance range, the sheet is considered to be within tolerance. However, if the measured thickness exceeds the upper or lower limit of the tolerance range, it indicates that the sheet is out of tolerance and may not meet the required specifications. In some cases, it may be necessary to consult with the manufacturer or supplier of the aluminum sheet to determine the specific tolerance requirements for a particular application. They can provide additional information and guidance regarding the appropriate thickness tolerance to ensure the sheet meets the intended purpose. Overall, determining the thickness tolerance of an aluminum sheet involves following industry standards, using accurate measuring equipment, and comparing the measured thickness to the specified tolerance range. This helps ensure that the sheet meets the required specifications and can be used effectively in various applications.

Send your message to us

500 Sheets of Aluminum Foil 9 In - Aluminium Two Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords