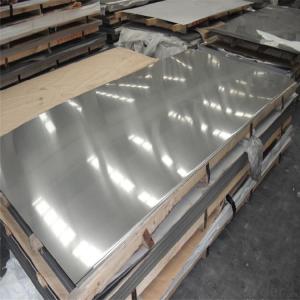

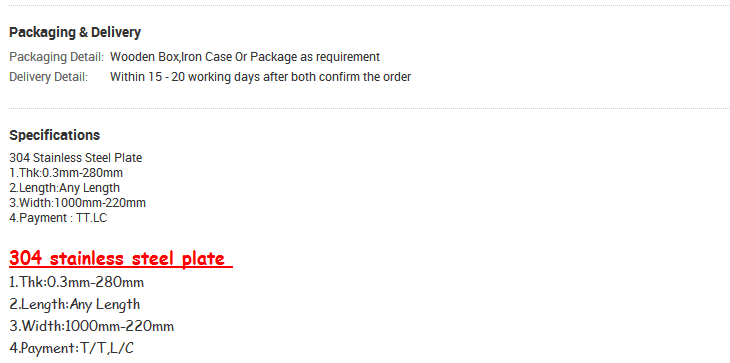

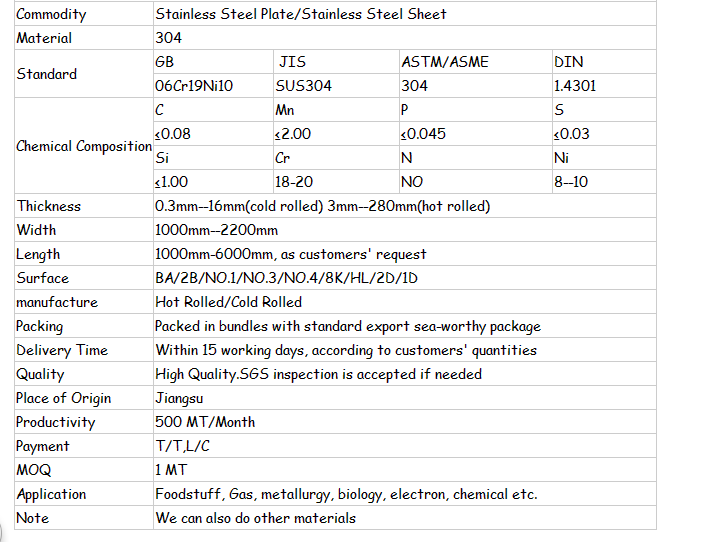

American Standard ASTM A240 304 Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Are stainless steel pipes suitable for wastewater treatment plants?

- Yes, stainless steel pipes are highly suitable for wastewater treatment plants. They offer excellent corrosion resistance, durability, and strength, ensuring long-term reliability and minimal maintenance requirements. Stainless steel pipes can withstand the harsh and corrosive conditions found in wastewater treatment plants, making them an ideal choice for conveying and handling various types of wastewater.

- Q: Are stainless steel pipes suitable for offshore platforms?

- Yes, stainless steel pipes are suitable for offshore platforms. They possess excellent corrosion resistance properties, which is crucial in marine environments where exposure to saltwater and harsh conditions is common. Stainless steel pipes can withstand the corrosive effects of seawater, ensuring the integrity and longevity of the offshore platforms' infrastructure. Additionally, their strength and durability make them suitable for handling high-pressure and high-temperature applications, making them a reliable choice for offshore platforms.

- Q: Are stainless steel pipes resistant to scaling and oxidation?

- Yes, stainless steel pipes are highly resistant to scaling and oxidation due to the presence of chromium in their composition, which forms a protective oxide layer on the surface, preventing corrosion and scaling.

- Q: What is the difference between seamless and cold-rolled stainless steel pipes?

- The main difference between seamless and cold-rolled stainless steel pipes lies in their manufacturing process and the resulting characteristics. Seamless stainless steel pipes are produced by piercing a solid cylindrical billet of stainless steel and then processing it through various steps such as elongation and reduction to achieve the desired size and shape. This process ensures that the pipe has a smooth and even surface, without any welded seams. As a result, seamless stainless steel pipes exhibit superior strength, durability, and resistance to corrosion. They are also known for their ability to withstand high pressure and temperature conditions, making them suitable for a wide range of applications, including oil and gas pipelines, chemical processing, and power generation. On the other hand, cold-rolled stainless steel pipes are manufactured by rolling stainless steel sheets or strips at room temperature. This process involves passing the material through a series of rollers to reduce its thickness and shape it into a cylindrical form. Unlike seamless pipes, cold-rolled pipes have welded seams that may be visible on the surface. While these seams can potentially weaken the pipe, they can be mitigated by applying additional processes such as heat treatment or cold working to enhance the strength and integrity of the weld. The choice between seamless and cold-rolled stainless steel pipes depends on the specific requirements of the application. Seamless pipes are generally preferred when high strength, corrosion resistance, and pressure resistance are critical, especially in industries where leaks or failure can have severe consequences. Cold-rolled pipes, on the other hand, may be more suitable for applications where cost-effectiveness and moderate performance are sufficient, such as certain plumbing systems or decorative purposes. In summary, seamless stainless steel pipes are produced without welded seams, offering superior strength, durability, and resistance to corrosion, making them ideal for demanding applications. Cold-rolled stainless steel pipes, with visible welded seams, are generally more cost-effective and suitable for less demanding applications that don't require the same level of strength and corrosion resistance.

- Q: Are stainless steel pipes suitable for heat recovery systems?

- Stainless steel pipes, indeed, prove to be apt for heat recovery systems. With its exceptional durability and resistance against corrosion, stainless steel emerges as an ideal material for applications that involve extreme temperatures and harsh environments. The primary objective of heat recovery systems is to seize and exploit waste heat generated from industrial processes, and stainless steel pipes efficiently handle the heat transfer procedure while ensuring their steadfastness over time. Moreover, stainless steel showcases remarkable thermal conductivity, which further enables efficient heat transfer. Consequently, the utilization of stainless steel pipes in heat recovery systems guarantees utmost performance and longevity.

- Q: Why can stainless steel pipes be welded by argon arc welding?

- The arc welding of argon arc welding has the advantages of stable combustion, concentrated heat, high temperature of the arc column, high welding efficiency, narrow heat affected zone, and little stress, deformation and crack tendency of the weldment;

- Q: What is the difference between the stainless steel pipe welded pipe and seamless pipe?

- Seamless tube is a strip of steel with a hollow cross section and no seams at all. The general is rolled into a cylindrical tube plate welding.

- Q: Difference between stainless steel and steel pipe

- Stainless steel (Stainless Steel) is referred to as the stainless steel, the resistance of air, steam, water and other weak corrosive medium or with stainless steel known as stainless steel; while the resistance to chemical corrosion (acid, alkali and salt chemical etching) corrosion of steel called acid resistant steel. Because of the difference in the chemical composition of the two, and make their corrosion resistance is different, ordinary stainless steel is generally not resistant to chemical medium corrosion, and acid resistant steel are generally stainless steel.

- Q: What is the external coating used for stainless steel pipes?

- The external coating used for stainless steel pipes can vary, but common options include epoxy, polyethylene, or polypropylene coatings.

- Q: How do you calculate the maximum allowable deflection for stainless steel pipes?

- The maximum allowable deflection for stainless steel pipes can be calculated using the formula provided by the applicable industry standards or codes, such as ASME B31.3 for process piping or ASME B31.1 for power piping. These standards consider factors such as the pipe material, diameter, wall thickness, temperature, pressure, and support conditions to determine the maximum allowable deflection. It is essential to consult the relevant standards or seek guidance from a qualified engineer to accurately calculate the maximum allowable deflection for stainless steel pipes.

Send your message to us

American Standard ASTM A240 304 Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords