Stainless Steel Metal Plate ASME 304 2B,NO.4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

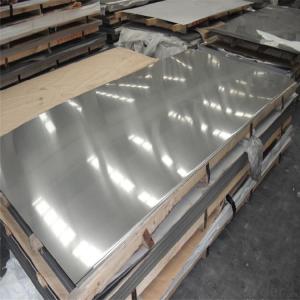

Stainless Steel Metal Plate ASME 304

Product Description

Model Name | Stainless Steel Metal Plate ASME 304 |

Type | 201,202,304,304l,316,316l,321,410,430 |

Color | Silver white |

Standard | ASTM, ASME, AISI, DIN |

Surface | No.1,No.4,2B,BA,HL,8K, mirror |

Thickness | 0.3-6.0mm, or as your requirement |

Width | 100mm-2000mm, or as your requirement |

Length | 1000mm-6000mm, or as your requirement |

Feature | Corrosion and heat resistance, good toughness |

Application | 1: Chemical industry equipment, industrial tanks 2: Medical instruments, tableware, kitchen utensil and kitchen ware. 3: Architectural purpose, milk or food processing facilities. 4: Hospital equipment, interior exterior decoration for building 5: Architectural purposes, escalators, kitchen ware and vehicles. Or they can be made as your requirement. |

Chemical Composition

Chemical composition of Stainless Steel 304 | ||||||||

chemical element | C | Si | Mn | P | S | Cr | Ni | Others |

Ingredient | <=0.07 | <=1.0 | <=2.0 | <=0.035 | <=0.03 | 17.0-19.0 | 8.0-11.0 | |

Physical Properties of Stainless Steel 304 | |

Tensile Strength (MPa) | 520 |

Compression Strength (MPa) | 205-210 |

Proof Stress 0.2% (MPa) | 205-210 |

Elongation A5 (%) | Min40 |

Hardness Rockwell B | 92 |

Packaging & Shipping

1.Packaging:All products are packaged according to the Standard export packing.In order to prevent friction damage and water erosion and so on.

2.Shipping: Ocean transportation,land transportation or air transportation.

- Q: How do you prevent distortion when welding stainless steel sheets?

- To prevent distortion when welding stainless steel sheets, there are several key steps and precautions that should be followed: 1. Proper preparation: Ensure that the stainless steel sheets are clean and free from any contaminants such as oil, grease, or dirt. Thoroughly clean the surfaces using a suitable solvent or degreaser before welding. This helps to prevent any impurities from being trapped in the weld, which can lead to distortion. 2. Proper fit-up: Accurate fit-up of the stainless steel sheets is crucial to minimize distortion. Ensure that the edges of the sheets are aligned properly and that there are no gaps or misalignments. Proper clamping or tacking can also help to maintain the correct position of the sheets during welding. 3. Controlled heat input: Heat control is essential to prevent excessive distortion. Using the appropriate welding technique, such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas), can help control the heat input. It is important to avoid overheating the stainless steel sheets as it can lead to warping and distortion. Maintaining a consistent and controlled heat input throughout the welding process is crucial. 4. Weld sequence: Proper planning of the weld sequence can also help to minimize distortion. Start from the center and work outward in a balanced manner to distribute the heat evenly. This prevents localized heating, which can cause distortion. Alternating between sides and allowing each weld to cool before moving to the next one can also help to reduce distortion. 5. Proper welding technique: Choosing the right welding technique and parameters is important. For instance, using a lower heat input, slower travel speed, and smaller weld bead can minimize distortion. Additionally, using a backstep technique, where the weld travels in a forward and backward motion, can help distribute the heat and reduce distortion. 6. Preheating and post-weld treatment: Preheating the stainless steel sheets can help reduce the temperature gradient and minimize distortion. The preheating temperature should be within the recommended range for the specific stainless steel grade. After welding, it is advisable to perform post-weld treatment, such as stress relieving, to minimize residual stresses that can lead to distortion. By following these steps and precautions, it is possible to significantly reduce distortion when welding stainless steel sheets. However, it is important to note that each welding process and stainless steel grade may have specific requirements, so referring to the manufacturer's guidelines and seeking professional advice is recommended for optimal results.

- Q: Are stainless steel sheets suitable for elevator control panels?

- Yes, stainless steel sheets are suitable for elevator control panels. Stainless steel is known for its durability, resistance to corrosion, and ease of maintenance, making it a popular choice for various applications including elevator control panels. It provides a sleek and modern appearance, can withstand constant use and touch, and is easy to clean and disinfect, making it an ideal material for elevator control panels.

- Q: How do you bend stainless steel sheets?

- Bending stainless steel sheets requires a combination of skill, knowledge, and the right tools. Here are the steps to bend stainless steel sheets effectively: 1. Determine the type of stainless steel you are working with: Stainless steel comes in different grades, each with its own unique characteristics. Knowing the specific grade of stainless steel will help you understand its malleability and how it responds to bending. 2. Prepare the stainless steel sheet: Before you begin bending, make sure the stainless steel sheet is clean and free of any dirt or debris. You can use a mild detergent and a soft cloth to clean the surface. 3. Mark the bending line: Measure and mark the exact spot where you want to bend the stainless steel sheet. Use a ruler or a straight edge to ensure a precise and straight line. 4. Use a suitable bending tool: There are various bending tools available for stainless steel sheets, such as a press brake, a rolling machine, or a bending machine. Choose the appropriate tool based on the thickness and size of the stainless steel sheet. 5. Apply pressure gradually: Place the stainless steel sheet into the bending tool, ensuring that it aligns with the marked bending line. Start applying pressure gradually, working your way from one end to the other. Avoid applying excessive force too quickly, as it can cause the sheet to crack or deform. 6. Adjust the bending angle: Depending on the desired angle of the bend, you may need to adjust the position of the stainless steel sheet within the bending tool. Use the tool's adjustments or additional tools like clamps to achieve the desired angle accurately. 7. Check the result: Once you have completed the bending process, carefully remove the stainless steel sheet from the bending tool. Inspect the bend for any defects, cracks, or unevenness. If necessary, you can use a rubber mallet or a hammer with a soft face to make minor adjustments. Remember, bending stainless steel sheets requires practice and precision. It is advisable to start with smaller projects and gradually work your way up to more complex bends. If you are unsure or lack experience, consulting a professional in metal fabrication is always a good idea to ensure the best results.

- Q: What industries commonly use stainless steel sheets?

- Several industries commonly use stainless steel sheets, including automotive, construction, food and beverage, aerospace, pharmaceutical, and chemical industries. Stainless steel sheets are valued for their durability, corrosion resistance, and versatility, making them suitable for a wide range of applications in these industries.

- Q: Can stainless steel sheets be used in food processing?

- Yes, stainless steel sheets are commonly used in food processing due to their hygienic properties, resistance to corrosion, and ease of cleaning, making them suitable for contact with food and ensuring food safety.

- Q: Are stainless steel sheets resistant to pitting and crevice corrosion?

- Yes, stainless steel sheets are generally resistant to pitting and crevice corrosion. Stainless steel is known for its high corrosion resistance due to the presence of chromium, which forms a passive oxide layer on the surface of the material, protecting it from corrosion. This oxide layer acts as a barrier, preventing the penetration of corrosive substances that could cause pitting and crevice corrosion. However, it is important to note that the resistance to pitting and crevice corrosion can vary depending on the specific grade of stainless steel and the environmental conditions in which it is exposed. Some grades of stainless steel, such as 316 or 317, have enhanced resistance to these types of corrosion. In addition, certain aggressive environments, such as those with high chloride concentrations or acidic conditions, can still pose a risk to stainless steel and may require the use of more corrosion-resistant grades or additional protective measures. Overall, stainless steel sheets are highly resistant to pitting and crevice corrosion, but the specific grade and environmental factors should be considered for optimal performance.

- Q: What are the different types of stainless steel sheet embossing patterns available?

- A variety of stainless steel sheet embossing patterns are available, offering different visual and tactile effects. Some of the most commonly used patterns are: 1. Diamond: This pattern consists of evenly spaced diamond-shaped indentations across the sheet's surface, creating an appealing textured appearance. 2. Linen: Resembling the texture of linen fabric, this pattern features parallel lines running in one direction and intersecting perpendicular lines, adding a subtle and sophisticated look to stainless steel sheets. 3. Stucco: The stucco pattern creates a raised, pebble-like texture on the sheet's surface, commonly used in architectural applications to enhance visual interest and provide a tactile feel. 4. Leather: This pattern imitates the texture of leather, with irregular lines and indentations, giving stainless steel sheets a unique and luxurious appearance. 5. Hammered: The hammered pattern showcases irregular indentations resembling hammer marks, contributing to a rustic and handcrafted look on stainless steel sheets. 6. Checkerboard: This pattern forms a grid of squares, with alternating squares raised or recessed, resulting in a classic and geometric design on stainless steel sheets. 7. Wave: The wave pattern showcases curved lines resembling ocean waves, adding a dynamic and flowing look to stainless steel sheets. These examples represent only a fraction of the available stainless steel sheet embossing patterns. Each pattern can be customized in terms of size, depth, and spacing to meet specific design preferences and application requirements.

- Q: What is the price range for stainless steel sheets?

- The cost of stainless steel sheets can fluctuate based on several factors, including the thickness, size, and grade of the stainless steel. Typically, thinner sheets begin around $30 per square foot, while thicker or higher-grade sheets can reach up to $150 per square foot. It is crucial to consider that market conditions and supplier pricing policies may also impact prices. Thus, it is advisable to compare prices from various suppliers before finalizing a purchase.

- Q: How do you determine the hardness of stainless steel sheets?

- To determine the hardness of stainless steel sheets, several methods can be used. One common method is the Rockwell hardness test, which measures the depth of indentation on the surface of the material. In this test, a diamond cone or steel ball is pressed into the sheet at a specific load, and the depth of penetration is measured. The Rockwell hardness value is then determined based on the depth of the indentation. Another method is the Vickers hardness test, which uses a diamond indenter to create a square-shaped indentation. The size of the indentation is measured and converted into a hardness value. This method is often used for thin materials like stainless steel sheets. Brinell hardness test is another technique that can be used. It involves applying a known load to the material using a hardened steel ball and measuring the diameter of the resulting indentation. The hardness value is then calculated based on the applied load and the diameter of the indentation. In addition to these mechanical tests, there are also non-destructive methods like ultrasonic hardness testing and magnetic hardness testing. Ultrasonic testing measures the speed of sound through the material, which is then correlated to hardness. Magnetic hardness testing measures the magnetic properties of the material, which are influenced by its hardness. Overall, the hardness of stainless steel sheets can be determined using various methods depending on the specific requirements and characteristics of the material.

- Q: What are the different types of stainless steel sheets available?

- There are several different types of stainless steel sheets available, including austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steel sheets. Each type has its own unique properties and characteristics, making them suitable for various applications in industries such as construction, automotive, and food processing.

Send your message to us

Stainless Steel Metal Plate ASME 304 2B,NO.4

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords