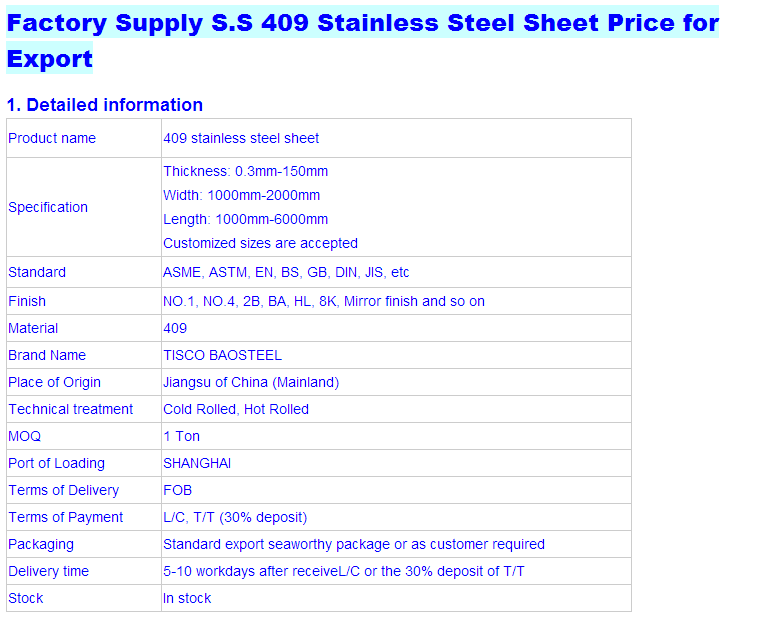

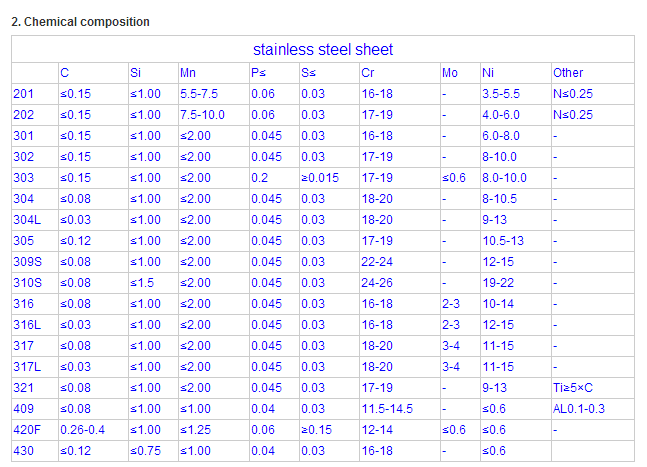

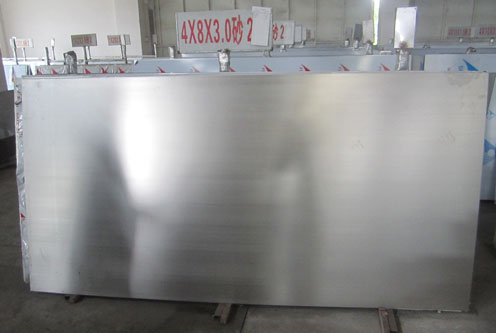

ASTM A240 SGS 409 Stainless Steel Plate Pheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Company Main Products:

Alloy Steel | 5140,5115,5120,5130,5145,4118,4130,4135,6150,5115,4142,4130,4118,6150,4140,4720,4320 ,E9310,8620,4340 |

Tool Steel | H13,1.2344,SKD61,D2,SKD11,1.2379,1.2510,01,SKS3,95MnWCr5,D3,SKD1,1.2419, SKS31,H21,SKD5,1.2581,P20,35CrMo7,1.2738,1.2316,M2 |

Bearing Steel | GCr15,52100,SUJ1,SUJ2,100Cr6,1.2067,55C,8620,4320,9310,440C,M50 |

Spring Steel | 9260,SUP6,SUP7,1.7108,54SiCr6,1.7102,5155,SUP9,1.7176,5160,1.7177,6150, SUP10,51CrV4,1.8159 |

Stainless Steel | 317,sus321,1.405,304,SUS304,1.4301,410,SUS410,1.4006,420,1.4021,1.4028, 434,1.4113,316L,SUS316L,1.4435,630,1.4542,431,1.4057,201,202,301,304,305.316 |

Production site:

- Q: Can stainless steel sheets be used for beer tanks?

- Yes, stainless steel sheets can be used for beer tanks. Stainless steel is a common material choice for beer tanks due to its durability, corrosion resistance, and hygienic properties. Stainless steel sheets are often used to construct the walls and inner surfaces of beer tanks to ensure the beer's quality and prevent contamination. The sheets can be fabricated and welded together to create a seamless tank that can withstand the pressure and temperature requirements of the brewing process. Additionally, stainless steel is easy to clean and maintain, making it an ideal material for beer tanks.

- Q: How do you remove oil stains from stainless steel sheets?

- In order to eliminate oil stains from stainless steel sheets, the following steps can be followed: 1. To start, utilize a clean cloth or paper towel to wipe the affected area and remove any excess oil or grease. 2. Combine a mild dish soap with warm water in a bowl or bucket. Dip a soft sponge or cloth into the soapy mixture and gently scrub the stained area using circular motions. 3. For more stubborn stains, a non-abrasive cleaner specifically designed for stainless steel can be employed. Apply a small amount of the cleaner to the stained area and utilize a soft cloth to rub it in. It is important to adhere to the manufacturer's instructions for the cleaner. 4. Thoroughly rinse the area with warm water to eliminate any soap residue. 5. To further restore shine and eliminate any remaining stains, a paste can be created by combining baking soda and water. Apply the paste to the stained area and allow it to sit for a few minutes. Then, gently scrub with a soft cloth or sponge. Rinse with warm water and dry with a clean towel. 6. To prevent future stains, it is advisable to consider using a stainless steel cleaner or polish. These products can aid in maintaining shine and making it easier to clean any spills or stains that may occur. It is essential to always test any cleaning product or method on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. Additionally, it is important to avoid using abrasive materials or scrub brushes with harsh bristles as they can cause scratches on the stainless steel.

- Q: Can stainless steel sheets be used for column covers?

- Yes, stainless steel sheets can be used for column covers.

- Q: Can stainless steel sheets be used for brewery piping?

- Certainly! Brewery piping can indeed utilize stainless steel sheets. Due to its corrosion resistance, durability, and hygienic qualities, stainless steel remains a favored material selection for brewery piping. It is capable of enduring the rigorous demands of the brewing process, including exposure to intense temperatures and harsh chemicals, thereby guaranteeing the integrity and cleanliness of the piping system. Moreover, stainless steel is effortlessly cleaned and maintained, rendering it exceptionally well-suited for breweries where cleanliness and sanitation are of utmost importance. In conclusion, stainless steel sheets are an unwavering and appropriate choice for brewery piping.

- Q: How do I prevent pitting on stainless steel sheets?

- To prevent pitting on stainless steel sheets, there are several steps you can take: 1. Choose the right grade of stainless steel: Different grades of stainless steel have varying resistance to corrosion. Opt for a higher-grade stainless steel, such as 316 or 304, which offer better resistance to pitting. 2. Proper cleaning and maintenance: Regularly clean the stainless steel sheets using mild soap or a non-abrasive cleaner. Avoid using harsh chemicals or abrasive scrubbers that can scratch the surface and create areas prone to pitting. 3. Avoid exposure to corrosive substances: Stainless steel sheets should be protected from prolonged exposure to corrosive substances like saltwater, strong acids, or chlorides. If the sheets are used in environments where exposure to these substances is unavoidable, consider applying a protective coating or finish. 4. Control the environment: Ensure that the stainless steel sheets are not exposed to excessive moisture, humidity, or high temperatures. These factors can accelerate corrosion and promote pitting. If possible, keep the sheets in a controlled environment with proper ventilation. 5. Regular inspection and maintenance: Perform regular inspections to identify any signs of pitting or corrosion. If pitting is detected, take immediate action to remove it and prevent further damage. Promptly repair any scratches or damages on the surface to prevent corrosion from starting. 6. Apply protective coatings: Consider applying a protective coating or film on the stainless steel sheets. These coatings act as a barrier against corrosive substances and can enhance the overall resistance to pitting. By following these preventive measures, you can minimize the risk of pitting on stainless steel sheets and ensure their longevity and durability.

- Q: What are the different types of stainless steel sheet edges available?

- There are several different types of stainless steel sheet edges available, each offering its own unique advantages and characteristics. 1. Mill Edge: This is the standard edge finish produced during the manufacturing process. It has a straight, sharp edge with no additional treatment or finishing. Mill edge stainless steel sheets are commonly used in industrial applications where aesthetics are not a priority. 2. Slit Edge: Slit edge stainless steel sheets are created by cutting the sheet along its length, resulting in a slightly rounded edge. This type of edge is commonly used in applications where safety is a concern, as it reduces the risk of sharp edges causing injury. 3. Sheared Edge: Sheared edge stainless steel sheets are created by cutting the sheet along its width using shearing blades. This process produces a clean, straight edge without any additional finishing. Sheared edge sheets are often used in applications where precise dimensions are required. 4. Deburred Edge: Deburred edge stainless steel sheets have gone through a process to remove any sharp or rough edges, resulting in a smooth and safe edge finish. Deburring is often done using abrasive materials or specialized machinery. These sheets are commonly used in applications where safety and aesthetic appearance are both important. 5. Rolled Edge: Rolled edge stainless steel sheets have a curved or rounded edge, created by rolling the sheet during the manufacturing process. This edge type is commonly used in applications where a smoother, more finished appearance is desired. Rolled edge sheets are also easier to handle and less likely to cause injury during installation. Overall, the choice of stainless steel sheet edge depends on the specific requirements of the application, including safety concerns, aesthetic preferences, and dimensional accuracy.

- Q: What is the corrosion resistance of stainless steel sheets?

- Stainless steel sheets possess excellent corrosion resistance due to the presence of chromium, which forms a protective oxide layer on the surface, preventing the metal from rusting or corroding in various environments.

- Q: Are stainless steel sheets suitable for elevator flooring?

- Yes, stainless steel sheets are suitable for elevator flooring. Stainless steel is a durable and corrosion-resistant material, making it an excellent choice for high-traffic areas like elevator floors. It can withstand heavy loads and is resistant to scratches, stains, and dents, ensuring a long-lasting and aesthetically pleasing flooring option. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for elevator flooring.

- Q: Can stainless steel sheets be used for water pipelines?

- Yes, stainless steel sheets can be used for water pipelines. Stainless steel is highly resistant to corrosion and has excellent strength, making it a suitable material for water pipelines that require durability and longevity. Additionally, stainless steel's smooth surface helps to maintain water flow efficiency and prevent contamination.

- Q: Can stainless steel sheets be used for decorative lighting fixtures?

- Yes, stainless steel sheets can certainly be used for decorative lighting fixtures. Stainless steel is a versatile and durable material that can be shaped and formed into various designs and patterns, making it ideal for creating unique and eye-catching lighting fixtures. Its sleek and modern appearance adds a touch of elegance to any space, making it a popular choice for decorative purposes. Additionally, stainless steel is resistant to corrosion and heat, ensuring that the lighting fixtures will remain in excellent condition for a long time.

Send your message to us

ASTM A240 SGS 409 Stainless Steel Plate Pheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords