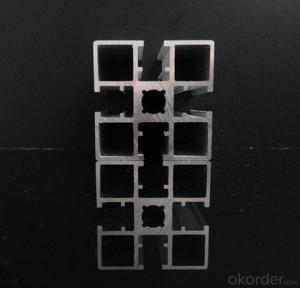

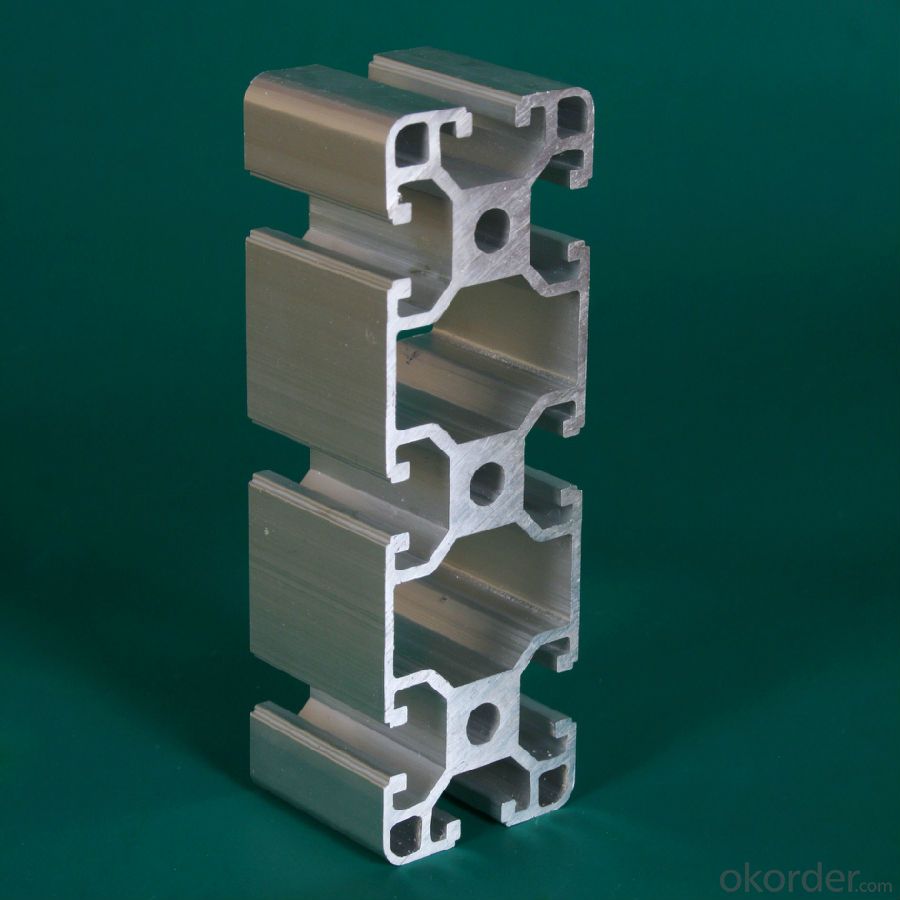

Aluminum Track Profiles - Alloy 6005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Product Name | Alloy 6005 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: Can aluminum profiles be used in the production of agricultural equipment?

- Aluminum profiles have the potential to be utilized in the manufacturing of agricultural equipment. The versatility and lightweight characteristics of aluminum provide numerous benefits for agricultural applications. Its resistance to corrosion is crucial when considering equipment that is exposed to outdoor conditions and various farming chemicals. Moreover, aluminum profiles have the capability to be easily molded and customized to meet specific design requirements, enabling the creation of intricate and functional agricultural equipment. The lightweight nature of aluminum also simplifies the transportation and handling of the equipment, resulting in reduced labor costs. Additionally, aluminum profiles are recyclable, making them an environmentally conscious choice for the production of agricultural equipment. In conclusion, incorporating aluminum profiles into agricultural equipment can enhance durability, efficiency, and sustainability within the farming industry.

- Q: This question asks about the various types of adhesives that can be used for bonding aluminum profiles to the frames of buildings.

- <p>There are several types of adhesives used to attach aluminum profiles to building frames, including epoxy resins, polyurethane adhesives, and silicone sealants. Epoxy resins are known for their high strength and resistance to chemicals and temperature changes. Polyurethane adhesives offer flexibility and are good for bonding different materials. Silicone sealants are used for their weather resistance and flexibility, making them suitable for exterior applications. Each type of adhesive has specific properties that make it suitable for different applications and environmental conditions.</p>

- Q: Explain the various methods used to install aluminum profiles in construction projects.

- <p>There are several methods to install aluminum profiles in construction: 1. Bolting: Aluminum profiles can be secured with bolts and nuts, providing a strong and adjustable connection. 2. Welding: For permanent and rigid connections, aluminum profiles can be welded together. 3. Adhesive bonding: Using specialized adhesives, aluminum profiles can be bonded together for a secure fit. 4. Clipping: Some profiles come with clip-on connectors that allow for quick and easy assembly. 5. Screwing: Self-tapping screws can be used to join aluminum profiles, providing a strong hold without the need for pre-drilled holes. 6. Mortise and tenon: A traditional woodworking joint that can be adapted for aluminum profiles, creating a tight and secure fit. Each method has its advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: What are the different packaging options for aluminum profiles?

- Aluminum profiles can be packaged in various ways to suit the specific needs and preferences of customers. Here are some common packaging options: 1. Bundling: Small profiles of the same length and shape can be bundled together using straps or bands. This option allows for easy handling and transportation. 2. Wooden crates: Larger or delicate profiles are often packed in wooden crates, which provide excellent protection during shipping. The crates can be customized to fit the profiles perfectly. 3. Cardboard tubes: Thin and lightweight profiles, such as those used in the packaging industry, can be packaged in cost-effective cardboard tubes. This option ensures lightweight transportation and storage with adequate protection. 4. Pallets: When dealing with a large volume of profiles, pallets are commonly used. The profiles are stacked and secured on the pallet using strapping or shrink wrap. Pallets allow for efficient handling using forklifts or pallet jacks. 5. Custom packaging: Customers with specific requirements can opt for custom packaging solutions. This may include foam inserts, plastic wraps, or personalized labeling. Custom packaging ensures proper protection and adherence to handling instructions. To summarize, the packaging options for aluminum profiles depend on factors such as size, fragility, and volume. Whether it's bundling, wooden crates, cardboard tubes, pallets, or custom packaging, each option offers its own benefits in terms of protection, handling, and transportation convenience.

- Q: How do you prevent galvanic corrosion when combining aluminum profiles with other metals?

- To avoid galvanic corrosion when combining aluminum profiles with other metals, there exist several effective measures that can be implemented: 1. Opt for compatible metals: Choose metals that are closely ranked in the galvanic series to minimize the potential difference between them. This decreases the likelihood of galvanic corrosion. For instance, utilizing stainless steel or titanium alongside aluminum can be a wise decision. 2. Insulate the metals: Employ insulating materials, like non-conductive coatings, paints, or tapes, to establish a barrier between the aluminum and other metals. This prevents direct contact and hinders galvanic corrosion. 3. Employ protective coatings: Administer protective coatings, such as anodizing or powder coating, to the aluminum surface. These coatings serve as a protective layer, preventing direct contact between the aluminum and other metals, thereby reducing the risk of galvanic corrosion. 4. Utilize isolating washers or gaskets: When fastening aluminum profiles to other metals, employ isolating washers or gaskets composed of non-conductive materials like rubber or plastic. These washers or gaskets create a barrier between the metals, thus preventing galvanic corrosion. 5. Consider design: Construct the structure in a manner that minimizes the potential for water or moisture accumulation between dissimilar metals. Adequate drainage and ventilation can help decrease the chances of galvanic corrosion. 6. Regularly maintain and inspect: Carry out routine inspections to promptly identify any signs of galvanic corrosion. If corrosion is detected, take appropriate action to rectify the situation, such as replacing damaged components or applying protective coatings. By adhering to these preventive measures, the risk of galvanic corrosion can be significantly diminished, ensuring the longevity and performance of the combined aluminum profiles and other metals.

- Q: This question asks for a description of the various dimensions and forms of aluminum profiles that are utilized in siding systems.

- <p>Aluminum profiles for siding systems come in a variety of sizes and shapes to accommodate different architectural styles and structural requirements. Common profiles include flat bars, channels, angles, and Z-profiles. Sizes can range from narrow trims of 10mm to wide panels of over 200mm in width, with thicknesses typically from 0.5mm to 3mm. Shapes are designed for specific functions, such as interlocking for a seamless appearance, or with grooves for attaching insulation. Custom profiles are also available for unique applications. These profiles are chosen based on the building's design, load-bearing needs, and aesthetic preferences.</p>

- Q: Can aluminum profiles be utilized in high-rise constructions that incorporate large windows?

- <p>Yes, aluminum profiles are commonly used in high-rise buildings with large windows due to their strength, durability, and lightweight properties. They offer excellent resistance to corrosion and weathering, making them ideal for external applications. Additionally, aluminum profiles can be easily customized to fit various window designs and sizes, providing both aesthetic and functional benefits. Their thermal break technology also helps in reducing heat transfer, enhancing energy efficiency in buildings.</p>

- Q: Can aluminum profiles be used in the construction of exhibition stands?

- Indeed, exhibition stands can be constructed using aluminum profiles. These profiles are renowned for their lightweight properties, durability, and ease of manipulation, making them a highly sought-after option for erecting exhibition stands. They can be effortlessly cut, molded, and assembled to fashion bespoke designs that precisely meet the exhibition's specific demands. Moreover, aluminum profiles can undergo powder-coating or anodization processes, yielding a plethora of finishes that enhance the exhibition stand's visual allure. Furthermore, aluminum possesses corrosion resistance and can endure diverse weather conditions, ensuring the exhibition stand's durability. All in all, utilizing aluminum profiles in the fabrication of exhibition stands confers adaptability, sturdiness, and an elegant aesthetic.

- Q: Can aluminum profiles be customized?

- Indeed, the customization of aluminum profiles is possible. Aluminum, being a versatile material, lends itself easily to shaping and modification in order to fulfill particular demands. Tailoring aluminum profiles involves a range of procedures like cutting, drilling, bending, welding, as well as surface treatments such as anodizing or powder coating. These diverse options for customization facilitate the creation of exclusive forms, dimensions, and finishes that perfectly suit specific applications and design requirements. Whether it is for architectural, industrial, or decorative applications, aluminum profiles can be personalized to meet individual specifications, thus establishing them as a favored choice across various industries.

- Q: Are aluminum profiles suitable for use in the construction of high-rise buildings?

- <p>Yes, aluminum profiles can be used in high-rise buildings. They are known for their high strength-to-weight ratio, which makes them ideal for structural applications where weight is a concern. Aluminum profiles are also resistant to corrosion and can withstand harsh weather conditions, making them a popular choice for exterior applications. Additionally, their recyclability and sustainability make them an environmentally friendly option. However, it's important to ensure that the aluminum profiles meet the specific load-bearing requirements and safety standards for high-rise construction.</p>

Send your message to us

Aluminum Track Profiles - Alloy 6005 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords