Aluminum T Slot Extrusion Profiles in Alloy 6063, 6061 with Temper T5, T6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium is a relatively soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. A fresh film of aluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector (as much as 98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa, while aluminium alloys have yield strengths ranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel. It is easily machined, cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spelling differences) are alloys in which aluminium (Al) is the predominant metal. The typical alloying elements are copper, magnesium, manganese, silicon, tin and zinc. There are two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable.

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5-6 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

Products are exported to United States, Canada, U.A.E, Brazil, Mexico,Thailand, Vietnam, Nigeria etc, over 100 countries and regions all over the world.

1. Application of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

2. Feature of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

3. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

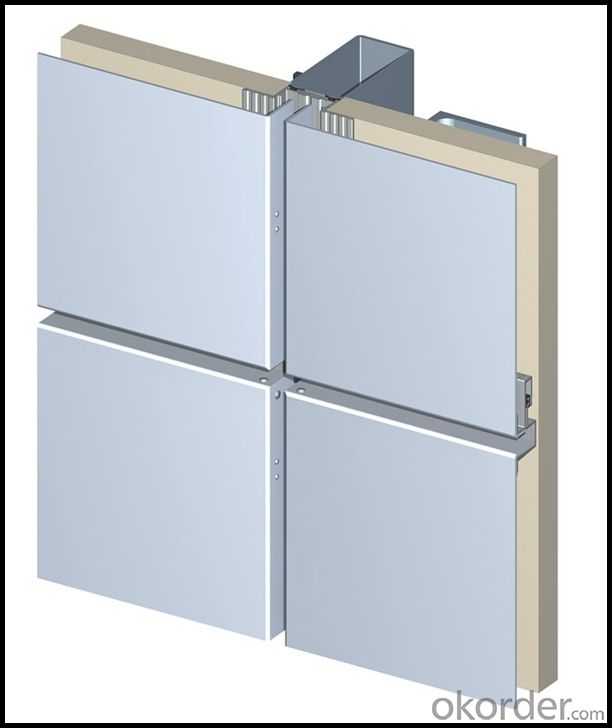

4. Image of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

5. Package and shipping of Perfils of Aluminum in Alloy 6063 6061 and Temper T5 T6

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

- Q: This question asks about the various types of aluminum profiles that are utilized in the construction of insulation systems.

- <p>Aluminum profiles used for building insulation come in various types, each serving specific functions. These include: 1. Insulation profiles, which provide a thermal barrier; 2. Structural profiles, used for structural support; 3. Cover profiles, which protect the insulation material; 4. Joint profiles, used for sealing joints; 5. Corner profiles, for reinforcing corners; 6. Edge profiles, for finishing edges; and 7. Special profiles, designed for specific applications. Each type is engineered to enhance thermal efficiency and structural integrity in building insulation systems.</p>

- Q: Can someone give me a direction? Thank you

- Look where you are and where you are. There are various directions for development, such as bags and so on, bathroom..

- Q: The surface of pure aluminum is relatively soft, too hard to be machined, and the other to be polished. If you want to harden the aluminum parts you produce. What's the way?. Please expert pointing

- Anodic oxidation attempts, on the surface, can form several um thickness alumina protective layers to improve corrosion resistance and abrasion resistance. In addition, if you can change materials, you can choose 2024T4 (Ying Lv).

- Q: This question asks if aluminum profiles can be utilized in the construction or design of interior wall systems.

- <p>Yes, aluminum profiles are commonly used for interior wall systems. They offer numerous benefits such as durability, lightweight, and resistance to corrosion. These profiles can be used in various applications, including partition walls, decorative panels, and structural supports. Their versatility allows for a wide range of design possibilities, and they are easy to install and maintain, making them a popular choice in modern interior design and construction.</p>

- Q: How do you cut aluminum profiles?

- If you need to cut aluminum profiles, there are a variety of methods available to you depending on the tools and equipment at your disposal. Here, we will discuss three commonly utilized techniques: 1. Power Saw: To effectively cut aluminum profiles, a power saw like a miter saw or circular saw equipped with a specialized carbide-tipped blade designed for metal cutting is recommended. Adjust the blade to the appropriate speed and angle for your desired cut, and carefully guide the saw through the profile, ensuring a smooth and precise cut. 2. Hacksaw: If power tools are not accessible, a hacksaw is a cost-effective and readily available alternative. Select a fine-toothed blade designed for cutting metal and securely fix the aluminum profile in a vise or workbench. Employ long, steady strokes to slice through the profile, applying gentle pressure to maintain control and prevent blade binding. 3. Shearing: For thinner aluminum profiles, a manual shear can be employed to make straight cuts. Position the profile in the shear, aligning the cutting edge with the desired cut line, and steadily exert pressure on the handle to allow the shear to effortlessly slice through the aluminum. This method is particularly suitable for cutting thinner profiles with precision and minimal risk of distortion. Regardless of the method you choose, it is crucial to wear appropriate safety gear, such as safety glasses and gloves, to safeguard yourself against metal shavings and sharp edges. Moreover, always accurately measure and mark your cut line before initiating the cutting process to ensure your desired outcome.

- Q: Are aluminum profiles suitable for use in chemical processing environments?

- Yes, aluminum profiles are suitable for use in chemical processing environments. Aluminum is a versatile and corrosion-resistant material that can withstand exposure to a wide range of chemicals. It has excellent resistance to many common chemicals, including acids, bases, and solvents. Additionally, aluminum profiles can be further protected by applying specialized coatings or finishes, such as anodizing, which enhances their resistance to chemical corrosion. Furthermore, aluminum profiles offer other advantages in chemical processing environments, such as their lightweight nature, high strength-to-weight ratio, and ease of fabrication. These qualities make aluminum profiles a preferred choice for various applications in chemical processing industries, including the construction of tanks, piping systems, and process equipment.

- Q: What are the different sealing options for aluminum profiles?

- There are several sealing options available for aluminum profiles, including anodizing, powder coating, liquid paint coating, and mechanical sealing. Anodizing is a popular choice, providing a durable and corrosion-resistant finish by creating a protective oxide layer on the surface of the aluminum. Powder coating involves applying a dry powder to the profile, which is then cured under heat to form a hard, smooth coating. Liquid paint coating can also be used, offering various colors and finishes, but may require more maintenance. Mechanical sealing involves using gaskets, tapes, or other sealing materials to create a tight seal between aluminum profiles. The choice of sealing option depends on the specific requirements of the application, such as desired aesthetics, durability, and environmental factors.

- Q: This question asks for methods to protect aluminum profiles from damage during the processes of transportation and storage.

- <p>To prevent damage to aluminum profiles during transportation and storage, follow these practices: Use protective packaging such as bubble wrap or foam padding to cushion the profiles. Ensure that profiles are stacked evenly and securely to avoid pressure points. Store profiles in a dry, cool place away from direct sunlight and moisture to prevent warping or corrosion. Secure the cargo during transportation to prevent shifting, and handle with care to avoid dropping or mishandling. Regularly inspect storage areas for potential hazards like pests or leaks that could cause damage.</p>

- Q: Can aluminum profiles be used for signage?

- Yes, aluminum profiles can be used for signage. Aluminum is a versatile and durable material that is commonly used for various signage applications. It offers several advantages such as being lightweight, corrosion-resistant, and easy to work with. Aluminum profiles can be easily formed into different shapes and sizes, making them suitable for a wide range of signage requirements. Additionally, aluminum profiles can be powder coated or painted to achieve the desired color and finish, enhancing the overall appearance of the signage. Moreover, aluminum is a sustainable material as it is highly recyclable, making it an environmentally friendly choice for signage projects. Overall, aluminum profiles are a popular choice for signage due to their durability, versatility, and aesthetic appeal.

- Q: What are the specific features of industrial aluminum profiles?

- What are the main characteristics of aluminum and aluminum alloys?1, small density: aluminum density of 2.7, about copper (8.9) or steel (7.8) 1/3. Low density for aerospace aircraft, ships, vehicles and buildings are very useful amount of light, but also can save the moving charges and processing fees, reduce the cost of application in industry, civil construction industry and other fields more widely;2, good corrosion resistance and weatherability: aluminum and Aluminum Alloy in the atmosphere to form a layer of hard and dense, with good corrosion resistance of oxide film by anodic oxidation, electrophoretic coating, powder coating and other surface treatment can improve the corrosion resistance of aluminum;3., good decoration: aluminum alloy has good plasticity, can process all kinds of specifications and formed products, through surface treatment, can produce different properties, different colors of the film, with good decorative;4.: good thermal conductivity aluminum thermal conductivity is very high, but silver, gold and copper in the metal, is 3 times the same weight of iron, aluminum is 12 times that of iron so Aluminum Alloy is a good material for manufacturing radiator, heater.Guangdong Changyuan aluminum technology: Aluminum Alloy profiles have the sun room, grape, pavilion, carport, sun canopy, window shelf,

Send your message to us

Aluminum T Slot Extrusion Profiles in Alloy 6063, 6061 with Temper T5, T6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords