Aluminum Structural Building Profiles - 6063 Alloy T5 Aluminium Profile for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

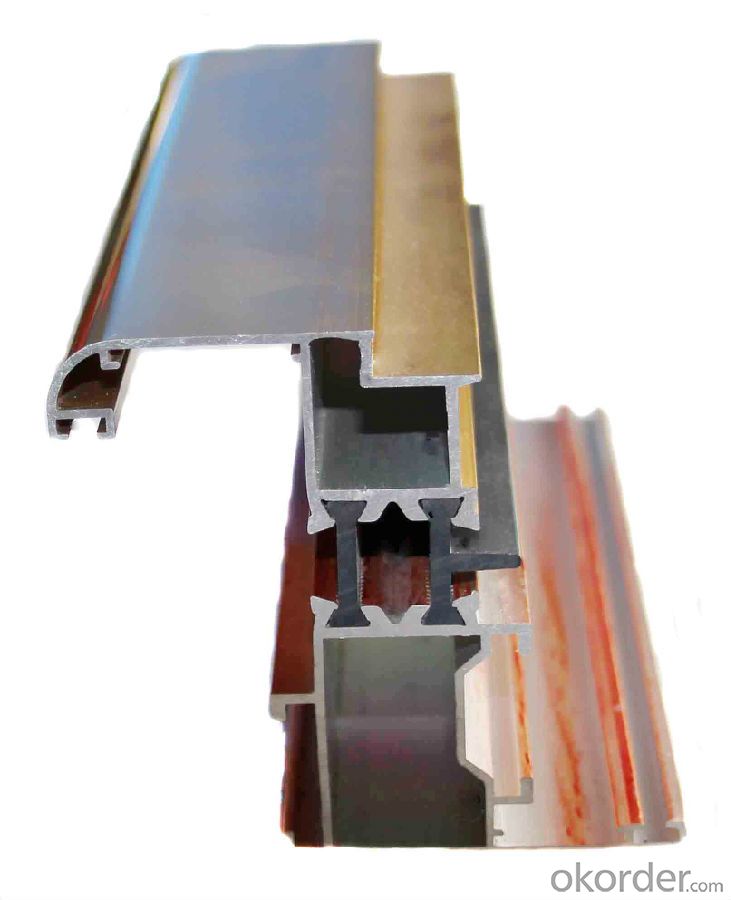

1.Structure of Aluminium Profile to Make Doors and Windows 6063 Alloy T5 Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile to Make Doors and Windows 6063 Alloy T5 :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

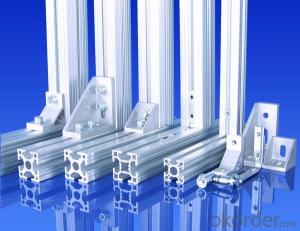

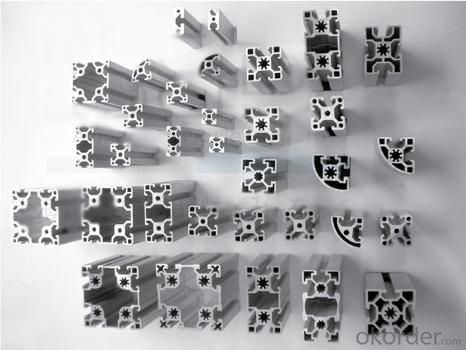

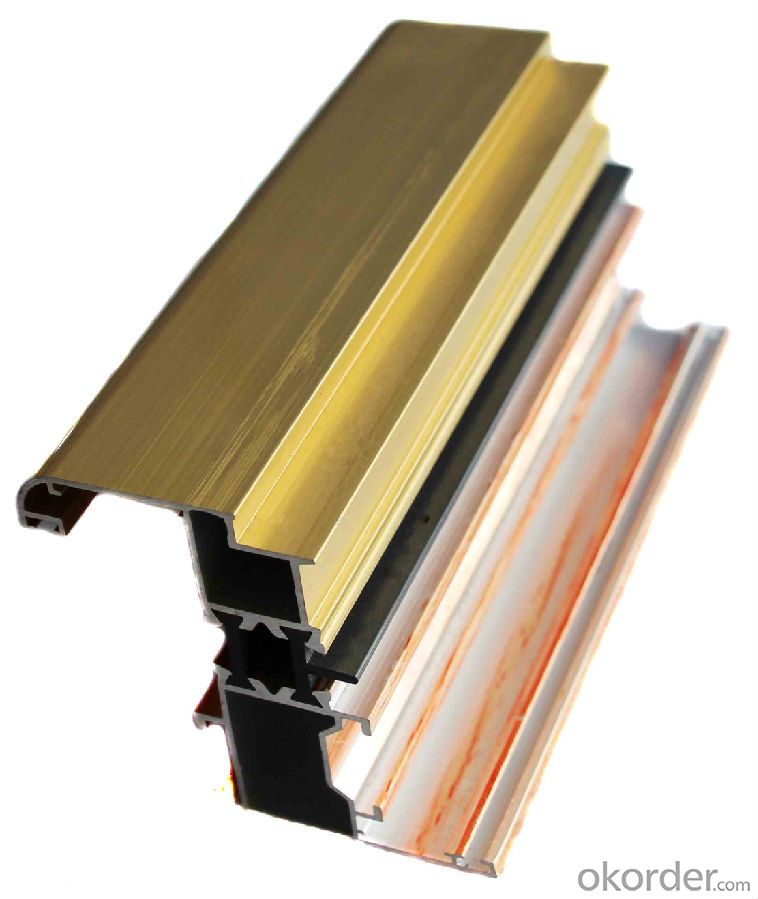

3.Aluminium Profile to Make Doors and Windows 6063 Alloy T5 Images:

4.Aluminium Profile to Make Doors and Windows 6063 Alloy T5 Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do aluminum profiles contribute to lightweight construction?

- Aluminum profiles play a significant role in lightweight construction due to their inherent properties and versatile applications. Firstly, aluminum is a lightweight material itself, with a density that is about one-third of steel. This means that using aluminum profiles instead of heavier materials like steel or concrete helps to reduce the overall weight of the structure or product. The lightweight nature of aluminum profiles brings several advantages to the construction industry. One of the key benefits is that it allows for easier handling and installation, reducing the need for heavy machinery and labor-intensive processes. This not only improves the efficiency of construction projects but also reduces costs. Moreover, the use of aluminum profiles in lightweight construction contributes to energy efficiency. Aluminum is an excellent conductor of heat and electricity, which means it can effectively dissipate heat and reduce energy consumption in buildings. This property is particularly beneficial for constructing energy-efficient buildings and helps to meet sustainability goals. Another aspect where aluminum profiles contribute to lightweight construction is their exceptional strength-to-weight ratio. Despite being lightweight, aluminum profiles possess high tensile strength, which makes them highly durable and capable of withstanding various loads and stresses. This characteristic allows for the design of strong and stable structures while minimizing material usage. Additionally, aluminum profiles offer design flexibility and versatility. They can be extruded into various shapes and sizes, enabling architects and designers to create complex and innovative structures. The ability to customize profiles according to specific project requirements enhances the architectural possibilities in lightweight construction. Furthermore, aluminum profiles are corrosion-resistant, which significantly extends their lifespan and reduces maintenance costs. This makes them suitable for applications in different climates and environments, including coastal regions where saltwater corrosion is prevalent. In summary, aluminum profiles contribute to lightweight construction by reducing the overall weight of structures, improving energy efficiency, providing strength and durability, offering design flexibility, and ensuring resistance to corrosion. These factors make aluminum profiles a preferred choice in a wide range of construction projects, from residential buildings to large-scale infrastructure.

- Q: Can you quote me one according to the current market situation?

- Aluminum: aluminum ingot + processing fee + Spray + heat insulationAluminum plate: square meter, unit price (depending on thickness) + spraying, etc.You cannot quote without specific parameters

- Q: The surface of pure aluminum is relatively soft, too hard to be machined, and the other to be polished. If you want to harden the aluminum parts you produce. What's the way?. Please expert pointing

- 1. anodized try, in the surface can form several um thickness alumina protective layer, improve corrosion resistance and wear resistance. In addition, if you can change materials, you can choose 2024T4 (Ying Lv).2.6063 aluminum alloy Brinell hardness should be about 12, Brinell hardness should be at 120-160HB. Hardness, physics, term in which materials resist the hard material pressing into its surface is called hardness. The local resistance of solids to the invasion of external objects is the index of soft and hard materials. There are different hardness standards due to different testing methods. The mechanical meanings of various hardness standards are different and can not be directly converted to each other, but they can be compared by experiment.

- Q: This question asks about the measures to be taken to ensure that the manufacturing process for aluminum profiles complies with environmental regulations.

- <p>To ensure that the production process for aluminum profiles meets environmental standards, you should implement a comprehensive environmental management system. This includes adhering to regulations on emissions, waste disposal, and resource usage. Monitor and reduce energy consumption, use eco-friendly materials, and optimize production processes to minimize waste. Regularly assess environmental impact, conduct audits, and seek certifications like ISO 14001. Engage in continuous improvement, invest in green technologies, and educate employees on environmental responsibilities. Collaborate with suppliers to ensure they also meet environmental standards.</p>

- Q: What are the noise reduction properties of aluminum profiles?

- Aluminum profiles have good noise reduction properties due to their ability to absorb and dampen sound vibrations. The high density and stiffness of aluminum help to minimize noise transmission, making it an effective material for reducing unwanted noise in various applications.

- Q: Do aluminum profiles require regular maintenance?

- Yes, aluminum profiles do require regular maintenance, although the frequency and extent of maintenance will depend on the specific usage and environmental conditions. Aluminum profiles are known for their durability and resistance to corrosion, but they can still accumulate dirt, grime, and oxidation over time. Regular cleaning with mild soap or detergent and water is recommended to remove dirt and maintain the appearance of the profiles. Additionally, lubrication of moving parts, such as hinges or sliding mechanisms, can help ensure smooth operation. Inspecting for any signs of damage, such as cracks or loose connections, is also important to address any issues before they worsen. Overall, regular maintenance helps to extend the lifespan of aluminum profiles and ensures their optimal performance.

- Q: Is it possible to recycle aluminum profiles and use them again in construction?

- <p>Yes, aluminum profiles can be recycled and reused in building construction. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to producing new aluminum. Recycled aluminum maintains its strength and properties, making it suitable for various construction applications. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: What are the anti-static properties of aluminum profiles?

- Due to their inherent electrical conductivity, aluminum profiles exhibit exceptional anti-static properties. This unique feature enables them to effectively dissipate static charges and prevent the build-up of static electricity. Consequently, aluminum profiles find widespread use in various industries, including electronics, automotive, aerospace, and manufacturing. In these sectors, they serve multiple purposes such as supporting conveyor systems, providing protective enclosures, and serving as grounding components. By minimizing the dangers associated with static electricity, such as electrostatic discharge (ESD) damage, fire risks, and interference with delicate electronic devices, the anti-static qualities of aluminum profiles guarantee safe and dependable operations.

- Q: Are aluminum profiles suitable for exterior cladding systems that need to withstand fire?

- <p>Yes, aluminum profiles can be used for exterior cladding systems that require fire resistance. Aluminum is a non-combustible material, which means it does not support combustion. However, it's important to note that while aluminum itself doesn't burn, it can melt at high temperatures. To enhance fire resistance, aluminum profiles can be coated with intumescent paint or used with fire-resistant materials in the cladding system. These measures can help to slow the spread of fire and protect the structure. Always ensure compliance with local building codes and fire safety regulations when selecting materials for fire-resistant applications.</p>

- Q: What are the dimensions of standard aluminum profiles?

- The dimensions of standard aluminum profiles vary depending on the specific application and industry standards. However, there are common dimensions that are widely used in various industries. Typically, the width of standard aluminum profiles can range from a few millimeters to several hundred millimeters. The height or depth of profiles can also vary, ranging from a few millimeters to several inches. In terms of length, standard aluminum profiles are often available in standard lengths of 6 meters or 20 feet. However, they can also be custom-cut to specific lengths as per the requirements of the project. Moreover, the thickness or wall thickness of aluminum profiles can vary depending on the intended use and load-bearing capacity. Generally, aluminum profiles have a thickness ranging from 0.5 millimeters to several millimeters. It is important to note that these dimensions are not fixed and may vary depending on the manufacturer, industry standards, and specific requirements of the project. Therefore, it is recommended to consult the manufacturer or supplier to determine the exact dimensions of standard aluminum profiles for a particular application.

Send your message to us

Aluminum Structural Building Profiles - 6063 Alloy T5 Aluminium Profile for Doors and Windows

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords