Aluminum Strip Coils for Metal Curtain Wall 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

1.Structure of Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

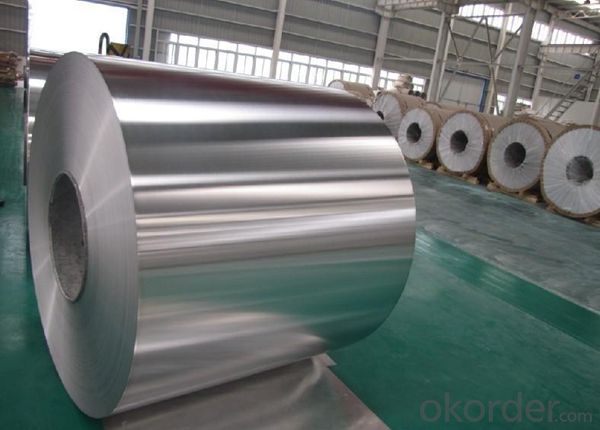

3. Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX Images

4.Specification of Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Aluminum Coil for Metal Curtain Wall 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Is it possible to determine the spring constant of an aluminum coil using a spring compressor?

- <p>Yes, you can use a spring compressor to measure the spring constant of an aluminum coil. The spring constant (k) can be calculated using Hooke's Law, which states that the force exerted by a spring is proportional to its displacement (F = kx). By applying a known force to the spring and measuring the resulting displacement, you can calculate the spring constant. A spring compressor can apply a controlled force, and a displacement gauge can measure the compression, allowing you to determine the spring constant accurately.</p>

- Q: This question asks for the most effective methods to clean an aluminum coil, which is a common component in various industries.

- <p>The best ways to clean aluminum coils involve a combination of mechanical and chemical processes. Mechanical cleaning can be done using brushes or pressure washing to remove loose dirt and debris. Chemical cleaning involves using a suitable aluminum cleaner or mild detergent solution to dissolve stubborn grime. Always rinse thoroughly with water to remove any residue. Avoid abrasive materials or harsh chemicals that could scratch the surface. Regular cleaning and maintenance can prevent buildup and extend the coil's lifespan.</p>

- Q: Can aluminum coils be used in the production of aluminum louvers?

- Yes, aluminum coils can be used in the production of aluminum louvers. Aluminum coils are a common raw material used in various industries, including the manufacturing of louvers. Aluminum coils are typically processed and formed into the shape and design required for louvers, providing the necessary strength and durability. The use of aluminum coils also allows for flexibility in design and customization of louvers to meet specific requirements. Additionally, aluminum is a lightweight and corrosion-resistant material, making it suitable for louvers that may be exposed to outdoor conditions. Overall, aluminum coils are widely used in the production of aluminum louvers due to their numerous advantages and suitability for this application.

- Q: I think the use of aluminum, at the lower levels, has really hurt US born players. To give a kid a piece of metal, and expect him to use wood when drafted........ I think US should go back to wood, whatever the costs (I know the aluminum is far cheaper). Thoughts....Cheers.

- You nailed it my friend. Aluminum has given our players a false sense of themselves and what they think they can do as a hitter. At the same time it is ruining the young pitchers when it comes to confidence. I have thought for years that it's destroying the game from within. Wood has always been the way to go. I would much rather hear the crack of the bat instead of the ping of the bat any day. Finally let's not forget the danger of aluminum bats. A line drive back to the mound comes off metal a lot faster than with wood. Pitchers are in harms way every time they throw a pitch!

- Q: What are the different surface treatments applied to aluminum coils?

- There are several different surface treatments that can be applied to aluminum coils to enhance their appearance, protect against corrosion, and improve their overall performance. Some of the most common surface treatments for aluminum coils include: 1. Anodizing: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of the aluminum. This treatment enhances the corrosion resistance of the coils and provides a decorative finish. Anodized aluminum coils are available in a wide range of colors and finishes. 2. Painting: Painting is a surface treatment that involves applying a coating of paint to the aluminum coils. This treatment provides a decorative finish and can also enhance the corrosion resistance of the coils. Painted aluminum coils are commonly used in architectural applications where aesthetics are important. 3. Laminating: Laminating is a process that involves applying a thin layer of protective film to the surface of the aluminum coils. This treatment provides a protective barrier against scratches, abrasion, and UV radiation. Laminated aluminum coils are often used in applications where durability and weather resistance are important. 4. Polishing: Polishing is a mechanical process that involves buffing the surface of the aluminum coils to create a smooth and shiny finish. This treatment enhances the appearance of the coils and can also improve their corrosion resistance. Polished aluminum coils are commonly used in decorative applications where a high-end look is desired. 5. Brushing: Brushing is a mechanical process that involves creating a pattern of fine parallel lines on the surface of the aluminum coils. This treatment gives the coils a brushed or satin finish and can also help to hide imperfections and scratches. Brushed aluminum coils are often used in applications where a modern and sleek appearance is desired. Overall, the choice of surface treatment for aluminum coils depends on the specific application requirements and desired aesthetic. Each treatment offers unique benefits in terms of appearance, corrosion resistance, and durability, allowing manufacturers and designers to select the most suitable option for their needs.

- Q: I was wandering, if your spear's shaft is made of aluminum, does that have any strength to it, i mean, say you had to block with the shaft, would a weapon break through like your basic sword or basic axe, i don't mean big heavy swords and axes, but like average ones, could it break through an aluminum shaft of a spear?

- nice question dear.. but strength is depend upon the hardness of material.. if that spear's shaft is hollow it can withstand up to certain level only for slow strikes.. but shaft is a rod hopefully i can say block using that even with a basic katana and Axe.. and one more thing your should strike as sparring and for fighting..

- Q: Can aluminum coils be used in solar panel systems?

- Solar panel systems can indeed utilize aluminum coils. Aluminum is commonly selected as the material for frames and supports in solar panels because of its favorable combination of lightness and strength. Its resistance to corrosion, durability, and impressive thermal conductivity make it an ideal choice for enduring severe weather conditions and efficiently dispersing heat generated by the panels. Furthermore, aluminum is highly recyclable, which aligns perfectly with the environmentally conscious nature of solar energy systems. In conclusion, incorporating aluminum coils into solar panel systems enhances their efficiency, lifespan, and eco-friendliness.

- Q: The user is asking if it's possible to recycle old aluminum coils to create new ones.

- <p>Yes, you can recycle old aluminum coils into new ones. Recycling aluminum is a highly efficient process, and it's very common in the industry. Aluminum has one of the highest recycling rates among metals due to its value and the energy savings associated with recycling compared to producing new aluminum from raw materials. When you recycle aluminum, it can be melted down and reformed into new coils or other products without losing its properties. This process helps conserve resources and reduces environmental impact.</p>

- Q: Are aluminum coils suitable for food packaging?

- Yes, aluminum coils are suitable for food packaging. Aluminum is a safe and widely used material for packaging food due to its excellent barrier properties, resistance to corrosion, and ability to maintain the freshness and quality of the packaged food products.

- Q: What are the potential fire hazards associated with aluminum coils?

- There are several potential fire hazards associated with aluminum coils. First and foremost, aluminum is a highly flammable material, which means it can catch fire easily and burn quickly. This poses a significant risk if there is an ignition source nearby, such as an open flame, electrical spark, or hot surface. Another potential fire hazard is the accumulation of dust, dirt, or other combustible materials on the aluminum coils. These substances can act as fuel for a fire, increasing the likelihood and intensity of combustion. It is important to regularly clean and maintain the coils to prevent the buildup of such materials. Aluminum coils are often used in HVAC systems, and if these coils are not properly installed or maintained, they can become a fire hazard. For instance, if the coils are not securely fastened or if there are loose electrical connections, it can lead to overheating and potentially cause a fire. Additionally, aluminum coils can cause electrical fires if they come into contact with live electrical wires or if there is a short circuit. This can happen if the coils are installed too close to electrical components or if there is a failure in the insulation or grounding of the system. Lastly, the use of flammable refrigerants in HVAC systems can also increase the fire risk associated with aluminum coils. If there is a leak or malfunction in the refrigerant system, it can create a flammable atmosphere around the coils, leading to a potential fire or explosion. To mitigate these fire hazards, it is crucial to follow proper installation guidelines, regularly inspect and maintain the coils, keep the surrounding area clean and free from combustible materials, and ensure that there are no electrical or refrigerant leaks in the system. It is also recommended to have fire detection and suppression systems in place to quickly respond to any potential fire emergencies.

Send your message to us

Aluminum Strip Coils for Metal Curtain Wall 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords