5754 Coated Aluminum Coil for Curtain Wall - Mill Finish Aluminum Coil 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finish Aluminium Coil for Curtain Wall 1XXX 3XXX 5XXX

1.Structure of Mill Finish Aluminium Coil for Curtain Wall 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Aluminium Coil for Curtain Wall 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

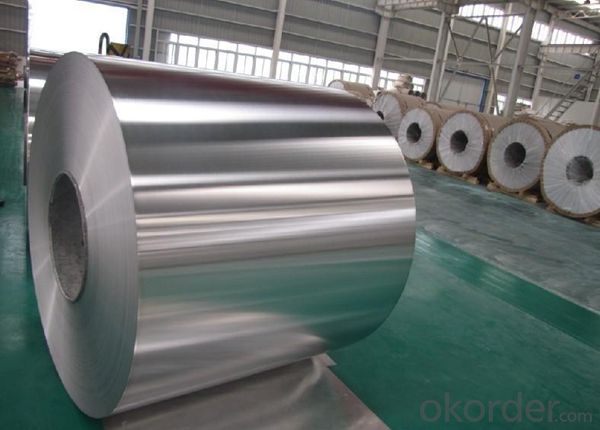

3. Mill Finish Aluminium Coil for Curtain Wall 1XXX 3XXX 5XXX Images

4.Specification of Mill Finish Aluminium Coil for Curtain Wall 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Aluminium Coil for Curtain Wall 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum coils be used in the production of aluminum composite ceilings?

- Yes, aluminum coils can be used in the production of aluminum composite ceilings. Aluminum coils are commonly used as the base material for manufacturing aluminum composite panels, which are then used in various applications including ceilings. The coils are processed and coated to meet the desired specifications and aesthetics of the composite ceiling panels.

- Q: I was wondering if you could mold clay into a sphere then fill it with aluminum. Then put it over a fire and wait until the aluminum melts then put it in a freezer and it would come out as a sturdy, aluminum sphere. Thanks!

- Do not try this at home! Seriously, this is exactly the kind of process that is used for casting metals. However, you need to have very strong molds with no cracks in them. Also, aluminum presents special problems. Solid aluminum does not corrode the way iron does, because it very quickly forms a protective tough layer of aluminum oxide. But molten aluminum can catch fire, with devastating consequences.

- Q: The general roll also 5,6t appearance, specific to your own weigh, length, weight = / (width * thickness * density)

- The density of aluminum is 2.7 and the molding weight is usually less than 3.5 tons, depending on the forming width and thickness. The wider, the thicker, the shorter.

- Q: What are the different types of surface coatings for aluminum coils?

- There are several different types of surface coatings that can be applied to aluminum coils. These coatings serve to protect the aluminum from corrosion, enhance its appearance, and improve its durability. Some of the common types of surface coatings for aluminum coils include: 1. Polyester: Polyester coatings are popular for their excellent color retention and resistance to fading. They provide a smooth, glossy finish and are commonly used for architectural applications. 2. Polyvinylidene Fluoride (PVDF): PVDF coatings offer exceptional weather resistance and durability. They are highly resistant to UV radiation, chemicals, and abrasion, making them suitable for outdoor applications and environments with harsh conditions. 3. Epoxy: Epoxy coatings provide good chemical resistance and adhesion. They are often used in industrial settings where corrosion protection is crucial, such as in chemical processing plants and marine applications. 4. Polyurethane: Polyurethane coatings are known for their durability and resistance to abrasion. They are commonly used in high-traffic areas or applications where the aluminum surface may be subjected to frequent contact or wear. 5. Acrylic: Acrylic coatings offer good weather resistance and color retention. They provide a smooth, glossy finish and are commonly used in architectural and decorative applications. 6. Plastisol: Plastisol coatings are a type of vinyl coating that provides excellent corrosion resistance and flexibility. They are often used in applications where the aluminum surface needs to withstand bending or forming without cracking or peeling. It is important to note that each type of coating has its own unique properties and advantages, and the choice of coating will depend on the specific requirements of the application, such as the level of corrosion resistance, aesthetic preferences, and environmental conditions.

- Q: Are aluminum coils fire-resistant?

- Yes, aluminum coils are fire-resistant.

- Q: 1) From What does aluminium derive its name?2)From which ore is aluminium extracted?3)Which country produces more aluminium than any other?4)An American and French scientist both patented the current process used to produce aluminium, what were there names?5)Who is credited with having been first to produce metallic aluminium?

- 1) From What does aluminium derive its name? Ancient Greeks and Romans used aluminium salts as dyeing mordants and as astringents for dressing wounds; alum is still used as a styptic. In 1761 Guyton de Morveau suggested calling the base alum alumine. In 1808, Humphry Davy identified the existence of a metal base of alum, which he at first termed alumium and later aluminum . The earliest citation given in the Oxford English Dictionary for any word used as a name for this element is alumium, which British chemist and inventor Humphry Davy employed in 1808 for the metal he was trying to isolate electrolytically from the mineral alumina. 2)From which ore is aluminium extracted? Bauxite 3)Which country produces more aluminium than any other? China 4)An American and French scientist both patented the current process used to produce aluminium, what were there names? Hall and Héroult 5)Who is credited with having been first to produce metallic aluminium? Friedrich W?hler

- Q: What are the common safety precautions when working with aluminum coils?

- To ensure the safety of individuals and prevent accidents, it is crucial to follow several safety precautions when handling aluminum coils. Here are some commonly recommended safety measures: 1. Personal Protective Equipment (PPE): It is essential to wear appropriate safety gear, such as safety goggles, gloves, and aprons, while working with aluminum coils. This protective equipment is necessary to safeguard against potential injuries from sharp edges, cuts, or burns. 2. Proper Handling Techniques: To avoid strain or injury, it is important to use proper lifting techniques while handling aluminum coils. Since these coils can be heavy, lifting with your legs instead of your back and using lifting aids or equipment, if required, is crucial. 3. Secure Storage: To prevent any accidents, it is vital to securely store aluminum coils. Avoid stacking them too high to prevent them from falling or rolling over and causing injuries. 4. Adequate Ventilation: To prevent the buildup of fumes or dust particles, it is important to ensure that the work area has proper ventilation. Aluminum coils may release harmful particles or gases during cutting or processing, making proper ventilation necessary for maintaining a safe working environment. 5. Fire Safety: Due to the high flammability of aluminum, it is extremely important to avoid sparks or open flames near aluminum coils. Using non-sparking tools and refraining from smoking or using flammable materials in the vicinity is crucial. 6. Sharp Edges: It is important to be cautious of sharp edges on aluminum coils as they can cause cuts or lacerations. Handling coils with care and using appropriate tools can help mitigate the risk of injury. 7. Training and Safety Guidelines: All personnel working with aluminum coils should receive proper training on handling procedures and safety guidelines. This includes knowing how to correctly use equipment, understanding emergency procedures, and being aware of any specific hazards associated with aluminum coil handling. 8. Regular Maintenance: Regularly maintaining equipment and tools is necessary to ensure they are in good working condition. This involves inspecting and repairing any damaged or worn-out parts that could pose a safety risk. 9. First Aid and Emergency Response: Keeping a well-equipped first aid kit nearby and ensuring that employees are aware of its location is important. Additionally, establishing clear emergency response protocols and training employees on what to do in case of an accident or injury is crucial. By following these common safety precautions, individuals can minimize the risks associated with working with aluminum coils and create a safer working environment.

- Q: A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

- Q: I have a mig welder, and I would like to learn to weld aluminum. I have been told that I must buy an aluminum wire spool gun, because the standard mig wire feeder gun will not work with aluminum wire. I don't understand why my standard wire feeder will not work. It feeds wire just like a spool gun. Why do I need to spend money on a spool gun just to weld aluminum? If a spool gun is truly necessary, where can i find one for a reasonable price? Thanks for your help!

- The problem with aluminum is it has to be super clean, and when you run the wire through a standard liner, especially if you've already run standard wire through it it picks up contaminates, making for some very nasty looking welds, however there are non metallic liner kits you can buy for it, the only problem is there a pain to change if you have to switch back and forth all the time. which is why most people just opt to buy a spool gun, and don't forget, you need to use 100% argon and not 25/75 argon co2 as you would with standard mig welding, so now your looking at a new tank also.

- Q: What are some common defects in aluminum coils?

- Aluminum coils may have several common defects, which are as follows: 1. Surface imperfections: Scratches, pits, dents, or waviness can be observed on the coil's surface. These defects may arise during manufacturing or due to mishandling during transportation or storage. 2. Edge irregularities: Coil edges might exhibit burrs or unevenness. Improper slitting or cutting processes can lead to such defects. 3. Coating abnormalities: When an aluminum coil is coated with a protective or decorative layer, issues like peeling, cracking, or uneven coating thickness may occur. These problems can be attributed to incorrect application or inadequate curing of the coating. 4. Corrosion: Although aluminum is generally resistant to corrosion, it can still be susceptible to corrosion in specific environments. Corrosion can manifest as pitting, staining, or the presence of white powdery deposits on the coil's surface. 5. Alloy flaws: In certain instances, the aluminum alloy used in the coil might contain defects such as inclusions, impurities, or an improper composition. These flaws can have an adverse impact on the coil's mechanical properties and overall performance. 6. Shape irregularities: Aluminum coils are expected to possess a consistent and uniform shape. However, defects such as coil set (where the coil retains a curvature after unwinding) or camber (where the coil exhibits a slight curvature across its width) can occur. These defects are usually caused by incorrect tension or cooling during the manufacturing process. 7. Welding defects: If the aluminum coil is produced by welding multiple sheets or strips of aluminum together, defects in the welds can occur. These defects include incomplete welds, cracks, or porosity, which can weaken the coil and compromise its structural integrity.

Send your message to us

5754 Coated Aluminum Coil for Curtain Wall - Mill Finish Aluminum Coil 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords