Mill Finish Aluminum PVC Coil for Metal Wall 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

1.Structure of Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

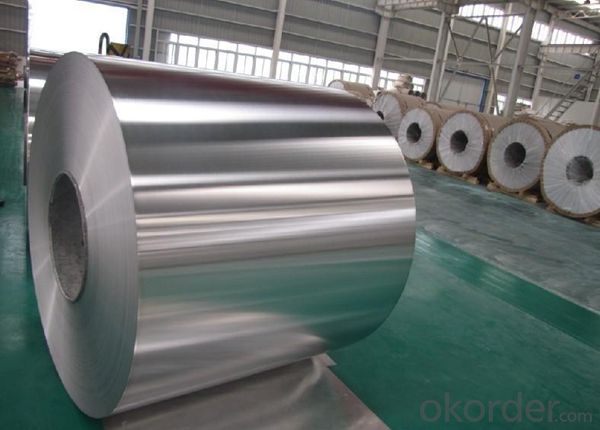

3. Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX Images

4.Specification of Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Mill Finish Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: This question asks for methods to prevent rust formation on aluminum coils during indoor storage.

- <p>To prevent rust on aluminum coils when storing them indoors, ensure that the storage area is clean and dry. Keep the coils away from moisture and humidity, as these can cause oxidation. Use protective wrapping or coverings to shield the coils from dust and airborne moisture. Regularly inspect the coils for any signs of condensation or dampness and address these promptly. Maintain proper ventilation in the storage area to reduce humidity levels. Additionally, avoid stacking the coils directly on the ground; use pallets or racks to elevate them, which helps in air circulation and prevents contact with moisture that could be present on the floor.</p>

- Q: Are there any specific regulations for the disposal of aluminum coil waste?

- Yes, there are specific regulations for the disposal of aluminum coil waste. It is important to adhere to local environmental laws and regulations, which typically require proper handling, storage, and disposal methods for aluminum coil waste. This may include recycling or sending the waste to licensed facilities for proper treatment and disposal. It is recommended to consult with local authorities or waste management agencies for specific guidelines and requirements.

- Q: What is the role of aluminum coils in the construction of ships?

- Aluminum coils are used in the construction of ships primarily for their lightweight and corrosion-resistant properties. They are commonly used in the fabrication of ship hulls, decks, and superstructures. The use of aluminum coils reduces the overall weight of the ship, improving fuel efficiency and increasing payload capacity. Additionally, the corrosion resistance of aluminum helps to prolong the lifespan of the ship, reducing maintenance costs in the long run.

- Q: Can aluminum coils be used in automotive heat exchangers?

- Yes, aluminum coils can be used in automotive heat exchangers. Aluminum is a popular choice for heat exchangers due to its excellent heat transfer properties, lightweight nature, and corrosion resistance. It is widely used in automotive radiators and air conditioning systems to efficiently transfer heat and cool the engine or cabin.

- Q: Are there any specific maintenance requirements for aluminum coils?

- Aluminum coils have specific maintenance requirements that must be met. These coils are commonly used in HVAC systems and need regular cleaning and maintenance to ensure they perform optimally and last a long time. Here are some of the maintenance tasks that should be done for aluminum coils: 1. Keep them clean: It is necessary to clean aluminum coils regularly to prevent the buildup of dirt, dust, and other contaminants. You can use a soft brush or a vacuum cleaner with a brush attachment to do this. Make sure to clean both the fins and the surface of the coils to ensure proper airflow. 2. Inspect them: Regularly inspecting aluminum coils is crucial to identify any signs of damage or corrosion. Look for bent fins, leaks, or any signs of wear and tear. If you notice any issues, address them immediately to prevent further damage. 3. Protect the coils: Applying a protective coating to aluminum coils can help prevent corrosion and extend their lifespan. There are various coatings available specifically designed for aluminum coils that provide an additional layer of protection against environmental factors. 4. Maintain air filters: The air filters in HVAC systems play a vital role in keeping the coils clean. Clean or replace the air filters regularly to prevent dust and debris from accumulating on the coils. Clogged filters can restrict airflow and reduce system efficiency. 5. Follow a maintenance schedule: It is crucial to establish a regular maintenance schedule to ensure all necessary tasks are completed on time. This schedule should include cleaning, inspection, and any other specific requirements recommended by the manufacturer. Consult the manufacturer's guidelines and recommendations for the specific maintenance requirements of your aluminum coils, as they may vary depending on the system and application. By following these maintenance requirements, you can ensure that your aluminum coils function efficiently and have a longer lifespan.

- Q: Can aluminum coils be used for heat transfer applications?

- Indeed, heat transfer applications can utilize aluminum coils. The commendable thermal conductivity of aluminum renders it remarkably efficient in transferring heat. In multiple heat transfer applications like air conditioning systems, refrigeration units, and heat exchangers, aluminum coils are frequently employed. The lightweight nature of aluminum, coupled with its resistance to corrosion, further contributes to its widespread preference in these applications. Moreover, the malleability of aluminum coils allows for the facile shaping and forming, thereby facilitating efficient heat transfer even in intricate systems.

- Q: How do aluminum coils compare to other metal coils like steel or copper?

- Aluminum coils have several distinct advantages compared to other metal coils like steel or copper. Firstly, aluminum is much lighter in weight, making it easier to handle and transport. Additionally, aluminum has excellent corrosion resistance, ensuring durability and longevity in various environments. Furthermore, aluminum coils have superior thermal conductivity, allowing for efficient heat transfer. Lastly, aluminum is more cost-effective compared to copper, while still providing reliable performance. Overall, aluminum coils offer a compelling combination of lightweight design, corrosion resistance, thermal conductivity, and cost-effectiveness when compared to steel or copper coils.

- Q: How are aluminum coils tested for quality control?

- Aluminum coils undergo several tests during quality control to ensure their reliability and performance. One of the primary tests is the dimensional inspection, where the physical dimensions of the coils are measured and compared against the specifications provided by the manufacturer. This helps to identify any discrepancies in length, width, thickness, or diameter. Another crucial test is the visual inspection, where the coils are thoroughly examined for any surface defects such as scratches, dents, or discoloration. This visual examination is essential to ensure that the coils meet the required aesthetic standards. To evaluate the mechanical properties, various mechanical tests are conducted. Tensile strength tests are performed to measure the resistance of the aluminum coils to breaking under tension. This test helps in determining the durability and strength of the coils. Additionally, hardness tests are carried out to assess the coil's resistance to indentation or deformation. The hardness values are compared against the predetermined standards to verify if the coils meet the necessary criteria. Further tests include corrosion resistance testing, where the coils are exposed to harsh environments or corrosive substances to assess their ability to withstand corrosion over time. This test is crucial as aluminum is often used in applications where it may come into contact with corrosive elements. Electrical conductivity tests are conducted to ensure the proper functioning of the coils in electrical applications. The conductivity is measured and compared with the required specifications to guarantee that the coils possess the desired electrical characteristics. In addition to these tests, other factors like chemical composition analysis, surface roughness evaluation, and coating adhesion tests may also be performed depending on the specific requirements of the aluminum coils. Overall, through these comprehensive quality control tests, manufacturers can ensure that aluminum coils meet the necessary standards, guaranteeing their quality, performance, and reliability in various applications.

- Q: Are aluminum coils suitable for automotive body panels?

- Indeed, automotive body panels can be effectively constructed using aluminum coils. The lightweight nature of aluminum greatly contributes to enhancing fuel efficiency and overall vehicle performance. Furthermore, the exceptional corrosion resistance of aluminum makes it an optimal selection for automotive applications, particularly when the panels are frequently subjected to diverse weather conditions. The impressive strength-to-weight ratio of aluminum further ensures outstanding durability and crash resistance. Moreover, aluminum allows for effortless formation and shaping, enabling the creation of intricate and fashionable designs. In conclusion, the utilization of aluminum coils for automotive body panels presents a multitude of benefits, making it a highly favored option for car manufacturers.

- Q: What is the role of aluminum coils in the construction of railways?

- Aluminum coils are used in the construction of railways for various purposes, primarily for the manufacturing of overhead lines and electrical conductors. Due to their high conductivity, lightweight nature, and corrosion resistance, aluminum coils are ideal for transmitting electrical power and ensuring efficient and reliable railway operations. These coils are also utilized in the production of railway carriages and components, providing strength and durability while reducing overall weight, which ultimately improves fuel efficiency and lowers operating costs. Overall, aluminum coils play a crucial role in enhancing the performance, safety, and sustainability of railway systems.

Send your message to us

Mill Finish Aluminum PVC Coil for Metal Wall 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords