Coil Sheet Aluminum for Metal Wall 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

1.Structure of Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

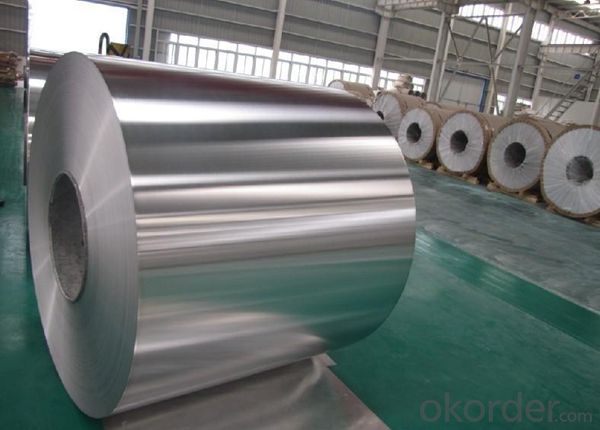

3. Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX Images

4.Specification of Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

Alloy Number | AA5XXX 1XXX 3XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ of Aluminum Coil for Metal Wall 1XXX 3XXX 5XXX

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum coils be painted?

- Indeed, it is possible to paint aluminum coils. By applying paint to aluminum coils, an extra layer of protection against corrosion can be achieved, along with an improvement in their aesthetic appearance. Nevertheless, it is crucial to properly prepare the surface prior to painting in order to ensure a strong adhesion and durability. This typically involves a thorough cleaning of the coils, the removal of any existing paint or coatings, and the application of a primer specifically designed for aluminum surfaces. Once the primer has dried, a suitable paint can be applied using a brush, roller, or spray. For optimal and long-lasting results, it is advisable to use a high-quality paint specially formulated for metal surfaces. Additionally, following the instructions provided by the manufacturer and taking into account any environmental factors, such as temperature and humidity, that could impact the painting process, is of utmost importance.

- Q: Are parakeets allergic to aluminum because I wanted to use a metal pie pan for a bird bath.

- ask a nice bird vet

- Q: Who knows Xingtai aluminum shutter door how much is one square meter?

- Two floor is right, you have to use a thick price on the high. A good job, 2012 way, is dead, and get a color to cope with it, ha ha.

- Q: How are aluminum coils stored to prevent damage?

- Aluminum coils are typically stored in a controlled environment to prevent damage. The storage area should be clean, dry, and well-ventilated to avoid any moisture buildup that could lead to corrosion. The coils are usually stacked on pallets or racks to keep them off the ground and protect them from any potential damage from dirt, dust, or water. It is important to ensure that the storage area is free from any sharp objects or heavy items that could potentially dent or scratch the coils. Additionally, the coils should be stored in a way that prevents them from shifting or falling, which could cause deformation or other damages. Proper labeling and organization of the coils is also crucial to easily identify and access them without causing any harm. Overall, careful attention to storage conditions and handling practices is essential to maintain the integrity and quality of aluminum coils and prevent any potential damage.

- Q: What are the potential applications of coil-coated aluminum coils?

- Coil-coated aluminum coils possess exceptional properties and versatility, thus presenting a wide range of potential applications. Some notable uses of coil-coated aluminum coils include: 1. Construction and Architecture: The construction industry extensively employs coil-coated aluminum coils for roofing, wall cladding, facades, and decorative elements. These coils can be easily shaped and customized to meet specific design requirements, while their coil coating ensures durability, weather resistance, and color retention. 2. Transportation: Coil-coated aluminum coils find widespread usage in the transportation industry, particularly in the manufacturing of automobiles, buses, trains, and aircraft. The lightweight nature of aluminum makes it an ideal choice for enhancing fuel efficiency and energy conservation. Moreover, the coil coating enhances corrosion resistance, aesthetics, and overall durability of the aluminum coils. 3. Appliances and Electronics: Manufacturing appliances and electronics, including refrigerators, air conditioners, ovens, and televisions, commonly involves the use of coil-coated aluminum coils. The coil coating provides a protective layer that prevents corrosion and extends the lifespan of these products. Additionally, the aesthetic appeal and variety of colors offered by coil-coated aluminum coils contribute to the overall design and aesthetics of appliances and electronics. 4. Signage and Displays: The versatility and visual appeal of coil-coated aluminum coils make them a popular choice for signage and displays. The coil coating enhances the durability, weather resistance, and color vibrancy of the aluminum, making it suitable for both indoor and outdoor applications. Whether it be large billboards, shop signs, or exhibition displays, coil-coated aluminum coils offer a cost-effective and visually appealing solution. 5. Packaging: Coil-coated aluminum coils are extensively used in the packaging industry for various purposes, such as cans, containers, and lids. The coil coating provides a protective layer that prevents the aluminum from reacting with the contents, ensuring product integrity and safety. Additionally, the lightweight nature of aluminum makes it an environmentally friendly option for reducing packaging waste. 6. Energy and Solar: The energy and solar industry is increasingly incorporating coil-coated aluminum coils. The lightweight and corrosion-resistant nature of aluminum make it an ideal material for manufacturing solar panels and energy-efficient systems. The coil coating further enhances the durability and weather resistance of the aluminum, ensuring long-term performance in different environmental conditions. In conclusion, coil-coated aluminum coils have vast and diverse potential applications, ranging from construction and transportation to appliances, signage, packaging, and the energy industry. The combination of excellent properties, including lightweight, durability, weather resistance, and aesthetic appeal, make coil-coated aluminum coils a preferred choice in numerous sectors.

- Q: Is it safe or advisable to use aluminum coil for wrapping food?

- <p>Using aluminum coil to wrap food is not recommended. Aluminum can react with acidic or alkaline foods, potentially leaching harmful aluminum particles into the food. It's also not designed for food contact and may not be safe at high temperatures. Instead, use food-grade aluminum foil, which is specifically designed for cooking and wrapping food, ensuring it doesn't come into contact with non-food surfaces that could contaminate it.</p>

- Q: What is the weight of an average aluminum coil?

- The weight of an average aluminum coil can vary depending on its size and thickness. However, as a general estimate, a standard aluminum coil with a thickness of 0.5mm to 1.5mm typically weighs around 1 to 3 tons. It is important to note that this is just an approximation and the actual weight can be higher or lower depending on the specific dimensions and properties of the coil.

- Q: What are the potential applications of colored aluminum coils?

- Colored aluminum coils have a wide range of potential applications across various industries. One of the main uses is in the construction sector, where colored coils can be used for both functional and aesthetic purposes. They can be applied as roofing material, siding, or decorative elements on buildings, providing protection against weather conditions while also enhancing the visual appeal of the structure. Another potential application is in the automotive industry, where colored aluminum coils can be used for manufacturing car body panels. The vibrant colors and durability of the material make it an attractive option for creating stylish and long-lasting exteriors for vehicles. Colored aluminum coils also find application in the electronics and electrical industries. They can be used to create casings for electronic devices, such as smartphones, tablets, and laptops, adding a visually appealing touch to these gadgets. Additionally, the lightweight nature of aluminum makes it a suitable choice for heat sinks and other cooling components in electronic devices. In the packaging industry, colored aluminum coils can be utilized for creating eye-catching packaging materials for various products. The vibrant colors and sleek appearance of aluminum can help to enhance the shelf appeal of consumer goods, attracting potential buyers. Furthermore, colored aluminum coils can be utilized in the furniture industry for creating modern and stylish furniture pieces. The versatility of aluminum allows for the production of unique designs and shapes, adding a contemporary touch to interior spaces. Lastly, colored aluminum coils can be employed in the signage and advertising industry. They can be used for creating custom signage, billboards, and promotional displays with vibrant and long-lasting colors, making them an effective marketing tool. Overall, the potential applications of colored aluminum coils are vast and diverse, spanning across industries such as construction, automotive, electronics, packaging, furniture, signage, and advertising. The durability, lightweight nature, and aesthetic appeal of colored aluminum coils make them a versatile material for a wide range of purposes.

- Q: I need to write as many interesting facts as i can about aluminum for a thing for school, any help?

- Aluminum, Motorcycle engine aluminum radiator made by precise die casting

- Q: Are aluminum coils suitable for insulation purposes?

- No, aluminum coils are not suitable for insulation purposes.

Send your message to us

Coil Sheet Aluminum for Metal Wall 1xxx 3xxx 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords