Aluminum Sheets Tennessee with Mill Finished Surface AA5xxx for Energy Saving Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Sheets with Mill Finished Surface AA5XXX for Energy Saving Curtain Walls

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Aluminum Sheets with Mill Finished Surface AA5XXX for Energy Saving Curtain Walls

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

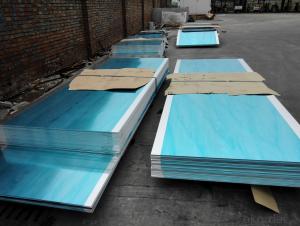

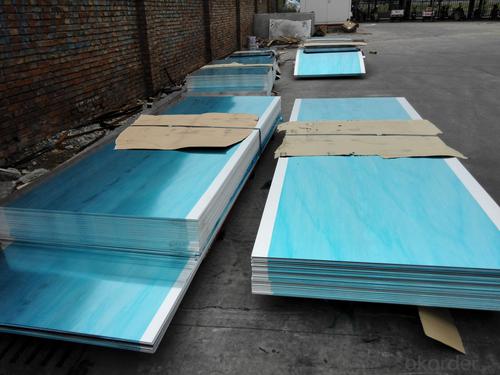

3. Aluminum Sheets with Mill Finished Surface AA5XXX for Energy Saving Curtain Walls Images

4.Specification of Aluminum Sheets with Mill Finished Surface AA5XXX for Energy Saving Curtain Walls

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: How can I make aluminum oxide?

- It turns out to be surprisingly difficult to do, because aluminum forms a skin of oxide which retards further oxidation. One way might be to react aluminum with sulfuric acid, getting aluminum sulfate in solution. Treat this with barium hydroxide; barium sulfate will precipitate out, leaving aluminum hydroxide in solution. Dry this and heat it, driving off the hydroxide as water and leaving aluminum oxide. I haven't tried this, so cannot guarantee that it will work.

- Q: How do you store aluminum sheets?

- Aluminum sheets should be stored in a dry and well-ventilated area, preferably indoors, to prevent corrosion. They should be stacked horizontally on a flat surface, with a protective covering such as plastic or cardboard between each sheet to avoid scratches. Additionally, it is advisable to separate different gauges or alloys to avoid galvanic corrosion. Regular inspection and maintenance are essential to ensure their longevity.

- Q: What is the tensile strength of aluminum?

- The tensile strength of aluminum varies depending on the specific alloy and temper. Generally, aluminum has a tensile strength ranging from 70 to 700 MPa (megapascals).

- Q: How much is the price of the 6061 aluminum plate?

- The price is very transparent on the 6061 aluminium plate market!Manufacturers also have several: there are Henan, Zhejiang, Guangdong, Chongqing, Shanghai, but the prices are almost the same.There are 6061 aluminum sheet, plate, state difference; prices are not the same.6061 aluminum sheet price: national standard sheet 0.8-5.0, thickness 38/ kgGB thick plate 5.0-300, thickness 27/ kgNon standard alloy aluminum plate 20-21/ kg

- Q: This question asks for methods to determine if a building is utilizing high-quality aluminum sheets.

- <p>To determine if a building is using high-quality aluminum sheets, look for the following characteristics: the sheets should have a uniform and smooth surface without visible defects or impurities. Check for a strong and consistent thickness throughout the material. High-quality aluminum is also resistant to corrosion and should not show signs of rust or pitting. Additionally, the sheets should be lightweight yet rigid, indicating a high strength-to-weight ratio. You can also inquire about the manufacturer's specifications and certifications, as reputable suppliers will provide detailed information about the quality and composition of their aluminum sheets.</p>

- Q: What is the typical shear strength of aluminum sheets?

- The typical shear strength of aluminum sheets can vary depending on the specific grade and thickness of the sheet. However, on average, aluminum sheets have a shear strength ranging from 100 to 200 MPa.

- Q: Are the aluminum sheets suitable for electrical conductivity applications?

- Yes, aluminum sheets are suitable for electrical conductivity applications. Aluminum is a highly conductive material, with an electrical conductivity approximately 61% that of copper. This makes it a popular choice for various electrical and electronic applications where conductivity is important. Aluminum sheets are used in the construction of power transmission lines, electrical cables, bus bars, and heat sinks, among others. Additionally, aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, which further enhances its suitability for electrical conductivity applications.

- Q: Can aluminum sheets be used for roofing?

- Yes, aluminum sheets can be used for roofing. Aluminum is a popular roofing material due to its durability, lightweight nature, and resistance to corrosion. It is commonly used in residential and commercial roofing applications.

- Q: What are the electrical conductivity properties of aluminum sheets?

- Aluminum sheets have excellent electrical conductivity properties due to their high thermal and electrical conductivity. They are widely used in various electrical applications, such as wiring, power transmission lines, and electrical enclosures.

- Q: i bought a light fixture for my bathroom wall and the ground wire is aluminum and the existing ground wire in the wall is copper,so i would like to know if i can join them and if so,how?

- Yes, in this case. Long ago, house wiring was allowed with aluminum wiring. But, shorts were resulting from dissimilar metals touching, while conducting large current and in the presence of electrolitic moisture. The dissimilar metals touching was a problem due to electrolytic corrosion taking place- any time two dissimilar metals come in contact in the presense of an electrolytic solution, corrosion takes place. However, in your case, you are connecting a ground wire, that does not normally conduct- it will only conduct in case of a short or other failure to ground. You are not installing this in a place where salty, moist air is a concern (the electrolyte)- so, it's okay.

Send your message to us

Aluminum Sheets Tennessee with Mill Finished Surface AA5xxx for Energy Saving Curtain Walls

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords