Aluminum Sheets in Utah - Aluminum Sheet 1050 1.2mm 3mm 6mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

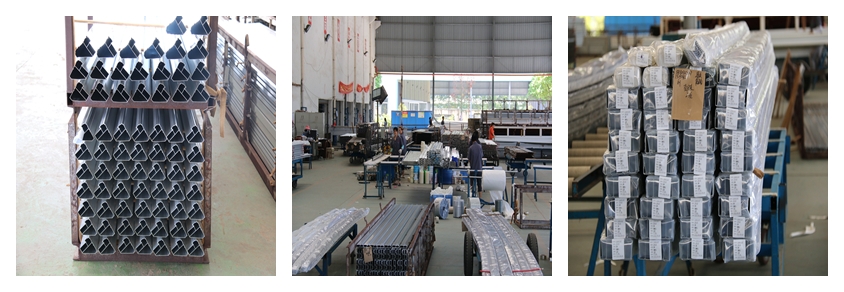

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: What is aluminium oxide sheet?

- Brief introduction:Advantage:(1) good processing: anodized aluminum decorative strong, moderate hardness, easy bending forming, continuous high-speed, convenient and direct processing into products, no need for complicated surface treatment, greatly shorten the production cycle and reduce production cost.(2) good weather resistance: standard thickness of oxide film (3 m) anodized aluminum plate, indoor use for a long time, no discoloration, no corrosion, no oxidation, no rust. Anodized aluminum oxide film (10 m) can be used outdoors, and can be exposed to sunlight for a long time without discoloration.(3) strong sense: the metal surface of aluminum anodic treatment of high hardness, as gem, scratch resistance, surface is not covered with paint, keep aluminum metal color, highlight the modern sense of metal, improve product quality and added value.(4) high fire resistance: pure metal products, the surface without paint and any chemical substances, 600 degrees high temperature does not burn, does not produce toxic gases, fire protection and environmental protection requirements.(5) strong dirt resistance: no fingerprints, no stain marks, easy cleaning, no corrosion spots.(6) applicability: it is widely used in metal aluminum ceiling, curtain wall board, aluminum plastic panel, fireproof board, honeycomb aluminum plate, aluminum veneer, electrical panel, cabinet panel, furniture panel and so on.

- Q: Are aluminum sheets lightweight?

- Yes, aluminum sheets are lightweight due to the low density of aluminum, making them ideal for various applications where weight is a concern.

- Q: Are aluminum sheets flammable?

- No, aluminum sheets are not flammable.

- Q: Can 101 aluminum sheets be anodized?

- Indeed, the anodization of 101 aluminum sheets is feasible. Anodization, which entails the formation of a safeguarding oxide layer on the aluminum's surface, enhances its resilience against corrosion and overall durability. This technique can be employed on different aluminum grades, including 101, to achieve desired finishes and offer added protection. The anodization process can be executed through diverse methods such as chromic acid anodizing, sulfuric acid anodizing, or hardcoat anodizing, depending on specific needs and desired outcomes. Consequently, it is assured that 101 aluminum sheets can undergo anodization procedures.

- Q: What are the different grades of aluminum sheets available?

- There are several different grades of aluminum sheets available, including 1100, 3003, 5052, and 6061. These grades vary in terms of their composition, strength, and intended use. 1100 aluminum is the most commercially pure grade and is often used for general purpose applications. 3003 aluminum is alloyed with manganese and has improved strength and corrosion resistance. 5052 aluminum is alloyed with magnesium and has excellent weldability and formability. 6061 aluminum is alloyed with magnesium and silicon and is known for its high strength and versatility.

- Q: What is the typical tensile strength of aluminum sheets?

- The typical tensile strength of aluminum sheets can vary depending on the specific alloy and temper, but it is generally in the range of 20,000 to 45,000 pounds per square inch (psi).

- Q: What is the specific heat capacity of aluminum sheets?

- The specific heat capacity of aluminum sheets is approximately 0.897 J/g·°C.

- Q: What are the different types of patterns available for textured aluminum sheets?

- Textured aluminum sheets offer a variety of patterns, each with its own unique visual appeal and functionality. Some commonly used patterns include: 1. Diamond pattern: Also called tread plate or checker plate, this pattern features small raised diamonds on the sheet's surface. It provides excellent slip resistance, making it ideal for applications that require traction, such as ramps, stairs, or industrial flooring. 2. Stucco pattern: Resembling a textured wall or ceiling finish, the stucco pattern has raised ridges that create a rough and bumpy surface. It is often used for decorative purposes, adding depth and visual interest to architectural elements like walls, ceilings, or furniture. 3. Hammered pattern: Mimicking the appearance of a surface hammered by hand, the hammered pattern creates a dimpled and uneven texture. It is commonly used in architectural applications, such as wall panels, backsplashes, or decorative accents, to add a rustic and artistic touch. 4. Brushed pattern: The brushed pattern is achieved by brushing the surface of the aluminum sheet with a wire brush, creating long, uniform lines. It offers a sleek and modern appearance, making it popular for applications like kitchen appliances, signage, or interior design elements. 5. Perforated pattern: Unlike the previous patterns, the perforated pattern involves creating small holes across the aluminum sheet's surface. This pattern is often used in applications that require ventilation, sound absorption, or decorative effects, such as speaker grills, filters, or façades. These examples highlight the range of patterns available for textured aluminum sheets. The choice of pattern depends on the specific project requirements, including aesthetics, functionality, and durability.

- Q: Can aluminum sheets be used for pharmaceutical lab equipment?

- Aluminum sheets have the capability to be utilized in pharmaceutical lab equipment. Aluminum, a versatile material, offers numerous benefits for pharmaceutical applications. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity make it an excellent option for constructing trays, shelves, and cabinets that are employed for storing and transporting pharmaceutical substances. Moreover, aluminum can be easily sterilized and cleaned, which is vital for maintaining hygienic conditions in pharmaceutical laboratories. Nevertheless, it is crucial to acknowledge that specific pharmaceutical procedures may demand materials that comply with particular regulatory standards. Thus, it is always wise to seek advice from industry experts or regulatory bodies to ensure that the selected aluminum sheets fulfill the necessary requirements for their intended usage in pharmaceutical lab equipment.

- Q: Are aluminum sheets suitable for lightweight structures?

- Yes, aluminum sheets are suitable for lightweight structures due to their low density and high strength-to-weight ratio.

Send your message to us

Aluminum Sheets in Utah - Aluminum Sheet 1050 1.2mm 3mm 6mm Thick

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords