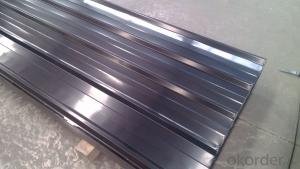

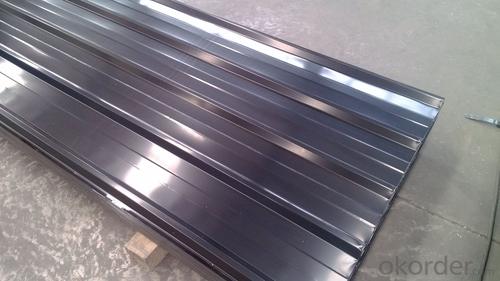

Aluminum Sheets in Pennsylvania - Extruded Aluminum Plate for Roofing Building Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

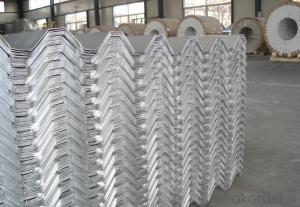

Extruded Aluminum Plate For Roofing Building Application

Specifications

Alloy NO. | Thickness | Width | Length | Production line | Circulation size |

1050 1060 1100 3003 | 0.3-9.5mm | 800--2200mm | 1000--10000mm | DC,CC | 1220*2440mm 1250*2500mm 1500*3000mm 1000*2000mm

|

5052 5083 5454 5754 5086 | 0.5-150mm | 800--2200mm | 1000--6000mm | DC | |

6061 | 5-150mm | 800--2200mm | 1000--10000mm | DC | |

7075 | 6-150mm | 800--2200mm | 1000--10000mm | DC | |

Packing | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | ||||

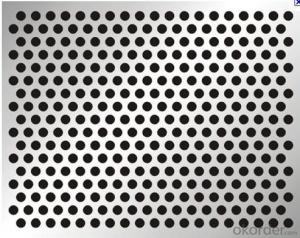

Application | decoration:ceilings,walls,furniture,cabinets,elevators,signs,name plate, transportation, cookware, household appliances:refrigerators,microwave ovens, machinery, mold making,aerospace and military aspects, auto, PP cap , construction etc | ||||

Standard | Chemical Composite: GB/T 3190-2008, JIS, EN, ASTM | ||||

Mechanical Property: GB/T 3880.2-2012, JIS, EN, ASTM | |||||

MOQ | 5TONS | ||||

Kind attention | Specifications can be customized as the customer’s requirements | ||||

Application

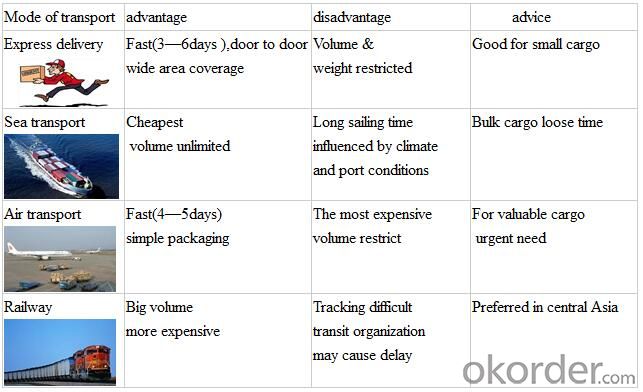

Shipment

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union, etc

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons.

- Q: This question asks for precautions or methods to protect aluminum sheets from damage during the installation process.

- <p>To ensure that the installation process does not damage aluminum sheets, follow these steps: Use protective gloves to avoid scratches from hand oils or dirt. Employ non-marring tools to prevent any indentations or marks. Handle the sheets carefully to avoid bending or denting. Keep the surface clean and dry to prevent any chemical reactions or stains. Use appropriate support structures to distribute weight evenly and prevent warping. Always follow the manufacturer's guidelines for installation to avoid any improper handling that could lead to damage. Regularly inspect the sheets for any signs of damage during the installation process and address any issues promptly.</p>

- Q: What are the different forming techniques for aluminum sheets?

- There are several different forming techniques that can be used to shape aluminum sheets. One common technique is called bending, which involves applying force to the sheet to bend it into a desired shape. This can be done manually using a press brake or through automated processes such as roll forming or stretch forming. Another technique is called deep drawing, which involves using a die and punch to stretch the aluminum sheet into a three-dimensional shape. This process is commonly used to create cylindrical or box-shaped components like cans or containers. Hydroforming is another forming technique that can be used for aluminum sheets. It involves using hydraulic pressure to shape the sheet against a mold or form. This technique is often used to create complex, irregular shapes that would be difficult to achieve with other methods. Spinning is a technique that is commonly used to create symmetrical shapes such as bowls or cones. It involves rotating the aluminum sheet against a mandrel while applying pressure to shape it into the desired form. Finally, there is also a technique called stamping, which involves pressing the aluminum sheet against a die to create a specific shape. This technique is often used for high-volume production of components such as automotive body panels. Overall, these forming techniques offer a range of options for shaping aluminum sheets into various forms and designs, allowing for flexibility and versatility in manufacturing processes.

- Q: what's the size of gap while pressing 6mm aluminum sheet?

- choose the 8-10% of the thickness for two-sided gaps.

- Q: What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- 6061, 1060, 7075, these we call "aluminum plate" brand, six beginning, we usually call six Department of aluminum, the beginning of a department of aluminum is pure aluminum, there are 1050, 1060, 1100, etc., aluminum content is more than 99%. Two at the beginning of the Al Cu alloy, 2024 and 2017, less domestic, belongs to aviation aluminum, in addition to the seven lines is the two most hard.

- Q: How do you prevent fingerprints on aluminum sheets?

- To prevent fingerprints on aluminum sheets, there are a few strategies you can employ: 1. Wear gloves: One of the easiest ways to avoid leaving fingerprints on aluminum sheets is to wear gloves while handling them. This will create a barrier between your hands and the surface, preventing any marks or smudges. 2. Clean the surface: Before handling aluminum sheets, make sure to clean the surface thoroughly. Use a suitable cleaning agent or a mild detergent to remove any dirt or oils that may be present. Dry the sheets completely with a lint-free cloth to minimize the chances of fingerprints sticking to the surface. 3. Use a protective coating: Applying a protective coating on the aluminum sheets can help prevent fingerprints. There are several options available, such as clear lacquer or a clear protective film specifically designed for this purpose. These coatings create a barrier that reduces the visibility of fingerprints and makes them easier to clean off. 4. Handle with care: When handling aluminum sheets, try to touch them as little as possible. Fingerprints are more likely to occur when you apply pressure or touch the surface repeatedly. If possible, use tools or gloves to manipulate the sheets instead of direct contact with your hands. 5. Store properly: Proper storage of aluminum sheets is crucial in preventing fingerprints. Ensure that they are stored in a clean and dust-free environment, away from any potential contaminants. Consider using protective sleeves or covers to shield the sheets from fingerprints and other marks. By employing these preventive measures, you can significantly reduce the occurrence of fingerprints on aluminum sheets, keeping them clean and visually appealing.

- Q: Can aluminum sheets be used for lithographic printing?

- Yes, aluminum sheets can be used for lithographic printing. Lithographic printing, also known as offset printing, relies on the principle that oil and water do not mix. Aluminum plates are used as the printing surface in lithography because they can retain an image when treated with a combination of chemicals. The image areas attract ink, while the non-image areas repel it. This allows for high-quality and precise printing.

- Q: What are aluminum sheets?

- Aluminum sheets, commonly found in various industries and applications, are thin and flat pieces of aluminum. Aluminum, a lightweight and versatile metal, is known for its exceptional strength, durability, and corrosion resistance, from which these sheets are made. Depending on the project's specific requirements, the thickness, width, and length of these sheets can vary. Construction, automotive, aerospace, packaging, and manufacturing industries, among others, widely employ aluminum sheets. They serve various purposes, including roofing, cladding, signage, transportation, electrical enclosures, and even household utensils. Aluminum's flexibility and malleability make it a popular choice for a wide range of applications, as it can be easily shaped and formed. Furthermore, aluminum sheets can be coated or finished, enhancing their appearance and protecting them from external factors like moisture, UV rays, or chemicals. In summary, aluminum sheets are indispensable materials that offer a combination of lightweight, strength, and corrosion resistance, making them ideal for industrial and commercial uses.

- Q: Can aluminum sheets be used for air ducts?

- Yes, aluminum sheets can be used for air ducts. Aluminum is a commonly used material for air ducts due to its lightweight and durable properties. It is resistant to corrosion, which makes it a suitable choice for HVAC systems. Aluminum sheets are often used to fabricate air ducts as they can be easily bent and shaped to fit the required dimensions. Additionally, aluminum has good thermal conductivity, allowing for efficient heat transfer within the ducts. Overall, using aluminum sheets for air ducts is a practical and effective choice.

- Q: How do I calculate the weight of aluminum sheet? What is the density?

- The density of aluminum is 2.7g/cm^3.

- Q: How do aluminum sheets compare to copper sheets in terms of conductivity?

- Aluminum sheets and copper sheets differ in terms of conductivity. Copper is known to be an excellent conductor of electricity, being one of the most conductive metals available. It has a high electrical conductivity, which means it allows electricity to flow through it with minimal resistance. On the other hand, aluminum is also a good conductor of electricity, but it is not as conductive as copper. Aluminum has approximately 61% conductivity compared to copper. Therefore, if high conductivity is a primary requirement, copper sheets would be the better choice. However, if cost-effectiveness and lightweight properties are more important, aluminum sheets can still provide sufficient conductivity for many applications. Ultimately, the choice between aluminum and copper sheets depends on the specific needs of the project and the balance between conductivity, cost, and other factors.

Send your message to us

Aluminum Sheets in Pennsylvania - Extruded Aluminum Plate for Roofing Building Application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords