Aluminum Sheets in Montana - Aluminium Coil/Plate Mill (China) Prime 5005 5010 5043 5050 H12 H16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

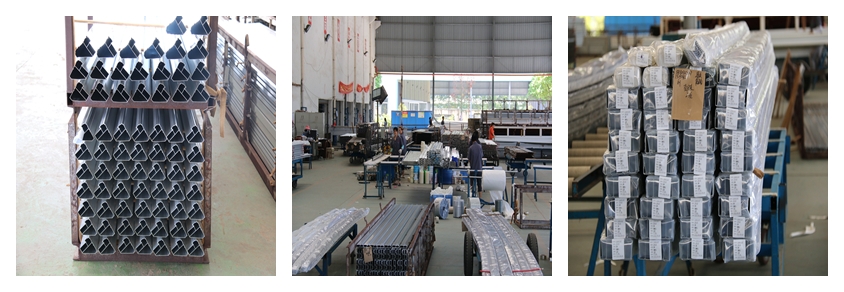

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: What specific treatments or coatings are required for exterior applications to ensure durability and protection?

- <p>Yes, for exterior applications, special coatings or finishes are often necessary to protect against weathering, UV radiation, and other environmental factors. These may include weather-resistant paints, UV-resistant coatings, and corrosion-resistant finishes. For example, in construction, exterior walls might be treated with a water-repellent coating to prevent water damage, while metal structures may require anti-corrosion coatings to withstand harsh weather conditions. The choice of coating depends on the material, climate, and specific requirements of the application.</p>

- Q: I've created a sculpture out of aluminum foil, but it's pretty flimsy. What can I paint or cover it with that would harden and support it? I was thinking a resin or something, but I have no experience with resins or epoxies... Any suggestions?

- Rigid Wrap is plaster-infused gauze. You can buy it at the art supply store or at a medical supply store. The latter is cheaper. It comes on a roll so you can cut off small chunks. Wet each piece and apply it to your sculpture. The first layer may be the most difficult. I would wrap the plaster gauze around the structure so the gauze overlaps gauze. It may not stick to the aluminum but it will stick to itself. Start at the bottom and let it dry, then add another layer. As mentioned, adding too much may compromise the structure so work slowly and allow time to dry between layers.

- Q: Can aluminum sheets be used for architectural facades?

- Architectural facades can indeed utilize aluminum sheets. This versatile material possesses numerous advantages for facade applications. Its lightweight nature, durability, and resistance to corrosion render it suitable for a variety of weather conditions. The fabrication and installation of aluminum sheets are effortless, enabling design flexibility and the creation of intricate and elaborate facades. Moreover, aluminum can undergo various finishes, such as powder coating, anodizing, or painting, to enhance its visual appeal and achieve the desired aesthetic. In summary, employing aluminum sheets for architectural facades empowers architects and designers with an extensive array of options to fashion visually captivating and enduring building exteriors.

- Q: What is the melting point of aluminum sheets?

- Aluminum sheets melt at around 660 degrees Celsius or 1220 degrees Fahrenheit.

- Q: Explain the similarities and differences in the properties of aluminum metal, Al(s) and aluminum oxide (a salt) Al203(s) in terms of the particles and forces present.. thanks doods!

- Aluminum metal is not found in nature, only aluminum oxide is in the mine or ground and they have to separate it from the oxidation to make a useful metal.

- Q: Hey.How come iron rust and aluminium does not?DETAILED ANSWER PLEASE.I want to understand this...THANKS.

- Aluminum and Iron both form an oxide coating on the surface of the pure metal. Iron oxide and aluminum oxide are very different however. Rust is very soft and wears away quickly, exposing a fresh Iron surface. Aluminum oxide is what a ruby is made from (along with a little Chromium for color). Rubies are only a bit softer than diamonds, the hardest substance known. The oxide coat on Aluminum is very thin but also very hard. It adheres to the surface and prevents any further corrosion. Regarding Chromium, it is the key ingredient in stainless steel. Steel is an Iron alloy with a small amount of Nickel, Molybdnium, Vanadium and even Copper and Phosphorus. Stainless steel resists rust so well because the Chromium will form an oxide coating the same way Aluminum does. Since the Chromium is actually part of the alloy, if the stainless steel is scratched, the fresh surface soon coats with a protective layer of Chromium oxide.

- Q: On the web page to see more information on the plating aluminum plate, I do not know what is the difference between aluminized and aluminum plating performance?

- Microstructure characteristics of hot dipped aluminized steelHot dip aluminizing steel to achieve the combination of atoms between iron and aluminum by metal bond, close together, as was shown under the microscope, from the outside to the inside with two aluminum film, three aluminum oxide layer, the alloy layer sequentially formed coating. If the coating of carbon steel, the banded structure and base metal contact.Coating thickness: if carbon steel, then the aluminum layer is 0.04-0.07mm alloy layer, the average 0.05mm. However, the thickness of each layer depends on the type of steel, the amount of carbon, and the temperature and time of the dipping. If the parent material is alloy steel, coating and the differences (omitted).

- Q: Can aluminum sheets be used for sound insulation?

- Yes, aluminum sheets can be used for sound insulation. Aluminum has good soundproofing properties due to its high density and ability to reflect sound waves. When used as a barrier or in combination with other sound-absorbing materials, aluminum sheets can effectively reduce noise transmission.

- Q: Can aluminum sheets be used for heat exchanger fins?

- Yes, aluminum sheets can be used for heat exchanger fins. Aluminum is a commonly used material for heat exchanger fins due to its excellent thermal conductivity, lightweight nature, and resistance to corrosion.

- Q: a dream I had where the carbon element was extracted from aluminum and ploished it became transparent, it was bendable and you could puncher it with out breaking it ?

- Aluminium is an element! Elements are pure substances, therefore aluminium doesn't contain any carbon. What do you mean?

Send your message to us

Aluminum Sheets in Montana - Aluminium Coil/Plate Mill (China) Prime 5005 5010 5043 5050 H12 H16

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords