Industrial Aluminum Foil Sheets - Price for 5052 Aluminium Sheet/Aluminium Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Price for 5052 Aluminium Sheet/ Aluminium Plate

l Specification

Commodity | Price for 5052 Aluminium Sheet/ Aluminium Plate |

Material | 1050,1060,1100,2A16(LY16),2A06(LY6),3003,3004,5052,5005,5083, 6061,7075,8011 |

Finish (Surface) | Hairline Finish,Mirror Finish,Oxidation Finish,PS Finish,Embossed Finish |

Thickness | 0.15mm~200mm |

Width | 10mm~2500mm |

Length | 2000mm~2500mm |

Application | Aluminium Sheet can apply to Lighting,solar reflective film,building appearance, interior decorating: Ceilings,walls, furniture,cabinets,elevators, signs, nameplates,bags,automotive interior and exterior decoration Upholstery:Photo Frame;household appliances:refrigerators,microwave ovens,audio equipment,etc. aerospace and military aspects, such as China's large aircraft manufacturing,the Shenzhou spacecraft series,satellite.the mechanical parts processing,mold making,chemical/thermal insulation pipes coated. |

Package | Standard seaworthy package (wooden boxes package,pvc package, and other package) |

Delivery Time | According to the quantity you ordered |

Payment Term | T/T,L/C,Western Union |

Advantage | Good quality with reasonable price |

l Packaging & Delivery

Packaging detail: wooden pallets that are suitable for long distance exporting

Delivery detail: 25-30 days after receiving L/C or payment in advance

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. Aluminium sheet is a popular product in CNBM. With best quality and service, we have won reputation around the world.. |

l CNBM World Wide

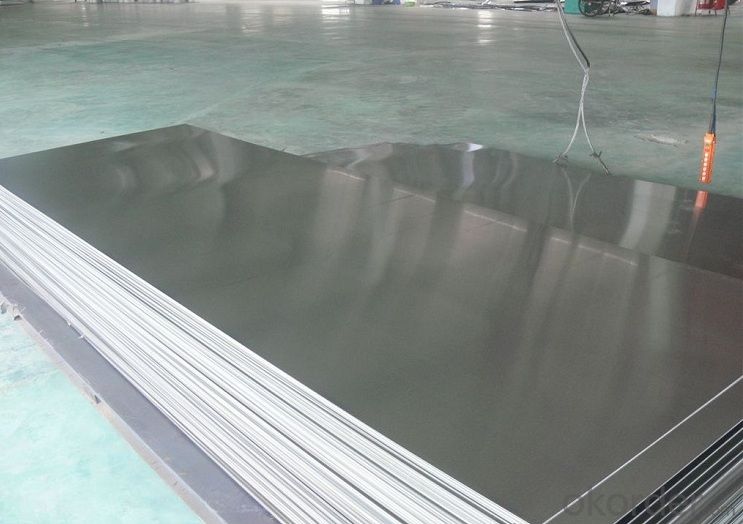

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: Are the aluminum sheets suitable for manufacturing aircraft fuselages?

- Yes, aluminum sheets are suitable for manufacturing aircraft fuselages. Aluminum is a popular choice for aircraft construction due to its high strength-to-weight ratio, corrosion resistance, and ease of fabrication. It is lightweight, which helps in reducing the overall weight of the aircraft, resulting in improved fuel efficiency and increased payload capacity. Additionally, aluminum can withstand the stresses and strains experienced by aircraft during flight. It is also a widely available and cost-effective material, making it a practical choice for aircraft manufacturers.

- Q: What are the different types of surface treatments for aluminum sheets in the marine industry?

- Aluminum sheets are extensively utilized in the marine industry due to their lightweight nature and resistance to corrosion. To enhance their durability and performance in marine environments, various surface treatments are employed. These treatments provide an added layer of protection against corrosion, oxidation, and other types of wear and tear. Several surface treatments are available for aluminum sheets in the marine industry. One common treatment is anodizing, which involves an electrochemical process that creates an oxide layer on the aluminum surface. This layer adds strength, improves corrosion resistance, and can be dyed for aesthetic purposes. Another method is powder coating, which enhances the appearance and durability of aluminum sheets. It involves applying a dry powder to the surface and heating it to create a protective coating. Powder coating offers excellent resistance against corrosion, UV rays, and scratches. Chromate conversion coating, also known as chemical film coating or chromating, is another surface treatment option. This process immerses the aluminum sheets in a solution containing chromate compounds, forming a thin layer of chromate conversion coating on the surface. This enhances corrosion resistance and provides a suitable base for subsequent painting or bonding. Paint coating is another surface treatment method in the marine industry. It not only enhances appearance but also protects against corrosion, saltwater, and harsh environmental conditions. Epoxy or polyurethane-based paints are commonly used for marine applications. Mechanical treatments, such as brushing, grinding, or polishing, can also be performed on aluminum sheets to improve their surface finish. These treatments remove impurities, smooth out imperfections, and enhance the overall appearance of the aluminum surface. Each surface treatment has its own advantages and is chosen based on the specific requirements of the marine application. By selecting the appropriate treatment, manufacturers can ensure that aluminum sheets meet the necessary performance and durability standards in the demanding marine industry.

- Q: Can aluminum sheets be used for heat shields in appliances?

- Appliances can utilize aluminum sheets as heat shields. Aluminum, being a lightweight and highly conductive material, effectively disperses heat. Its ability to withstand high temperatures is due to its high melting point, making it an ideal material for heat shield purposes. Furthermore, aluminum's corrosion resistance guarantees the durability and longevity of the heat shield. Its flexibility enables easy installation and shaping to accommodate different appliance designs. Aluminum sheets find widespread use in appliances like ovens, grills, and heating units as a safeguard against excessive heat, preventing potential damage to surrounding areas.

- Q: How do aluminum sheets perform in terms of wear resistance?

- Aluminum sheets have good wear resistance due to their natural ability to form a protective oxide layer on their surface. This oxide layer helps to prevent corrosion and wear, making aluminum sheets suitable for various applications requiring durability and resistance to wear.

- Q: Are the aluminum sheets suitable for manufacturing architectural wall panels?

- Yes, aluminum sheets are suitable for manufacturing architectural wall panels. They are lightweight, durable, and can be easily shaped and formed into various designs. Additionally, aluminum is resistant to corrosion, making it suitable for outdoor applications.

- Q: Can aluminum sheets be used in outdoor environments?

- Yes, aluminum sheets can be used in outdoor environments. Aluminum is highly resistant to corrosion and is known for its durability, making it a suitable material for various outdoor applications such as roofing, siding, and signage. Additionally, aluminum sheets can withstand exposure to weather elements like rain, sunlight, and temperature fluctuations, making them an excellent choice for outdoor use.

- Q: Are aluminum sheets suitable for aircraft manufacturing?

- Yes, aluminum sheets are suitable for aircraft manufacturing. Aluminum is widely used in the aerospace industry due to its unique combination of properties such as lightweight, high strength, corrosion resistance, and excellent formability. These characteristics make aluminum an ideal material for constructing various aircraft components, including fuselages, wings, and structural parts. Additionally, aluminum alloys can be easily joined, allowing for efficient manufacturing processes. Overall, aluminum sheets play a crucial role in aircraft manufacturing, contributing to the overall performance, durability, and safety of the aircraft.

- Q: Are 101 aluminum sheets suitable for conductive heat transfer applications?

- No, 101 aluminum sheets are not suitable for conductive heat transfer applications as they do not have good thermal conductivity properties.

- Q: What are the benefits of using aluminum sheets?

- There are several benefits of using aluminum sheets in various applications. Firstly, aluminum sheets are lightweight, making them easy to handle and transport. This characteristic is particularly advantageous in industries such as aerospace, automotive, and construction, where weight reduction is crucial for fuel efficiency and overall performance. Secondly, aluminum sheets offer excellent corrosion resistance. Unlike other metals, aluminum naturally forms a protective oxide layer when exposed to air, preventing further corrosion and enhancing its durability. This makes aluminum sheets highly suitable for outdoor applications or in environments with high humidity or corrosive substances. Another benefit of using aluminum sheets is their high strength-to-weight ratio. Aluminum is known for its exceptional strength, allowing it to withstand heavy loads or extreme conditions without compromising its structural integrity. This makes it an ideal choice for constructing lightweight but sturdy structures, such as building facades, vehicles, or industrial equipment. Additionally, aluminum sheets are highly malleable and ductile, meaning they can be easily formed into various shapes and sizes. This flexibility allows for intricate designs and customization, making aluminum sheets highly versatile and adaptable to different manufacturing processes or project requirements. Furthermore, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, meaning it can be reused repeatedly without losing its properties or quality. Recycling aluminum requires significantly less energy compared to the production of primary aluminum, resulting in reduced carbon emissions and a reduced environmental impact. Lastly, aluminum sheets have excellent thermal and electrical conductivity properties. This makes them suitable for applications that require efficient heat transfer or electrical conductivity, such as heat exchangers, solar panels, or electrical wires. Overall, the benefits of using aluminum sheets include their lightweight nature, corrosion resistance, high strength-to-weight ratio, malleability, sustainability, and excellent thermal and electrical conductivity. These advantages make aluminum sheets a popular choice in various industries, contributing to improved performance, cost-effectiveness, and environmental sustainability.

- Q: What are the mechanical properties of aluminum sheets?

- Aluminum sheets are highly sought after in various industries due to their unique mechanical properties. To begin with, they possess an exceptional strength-to-weight ratio, making them both lightweight and strong. This quality is particularly valuable in industries like aerospace and automotive, where reducing weight is crucial. Furthermore, aluminum sheets are highly malleable, allowing them to be easily shaped and formed into different sizes and configurations. This versatility makes them ideal for applications that require complex shapes, such as the manufacturing of cans, appliances, and architectural components. In addition, aluminum sheets have a high resistance to corrosion, thanks to the development of a thin, protective oxide layer on their surface. This durability makes them suitable for outdoor applications or environments with high moisture or chemical exposure. Moreover, aluminum sheets exhibit excellent thermal conductivity, enabling them to efficiently transfer heat. This property makes them widely used in heat exchangers, cooling systems, and other applications where effective heat dissipation is necessary. Lastly, aluminum sheets possess good electrical conductivity, allowing them to effectively conduct electricity. This makes them suitable for electrical enclosures, conductors, and other electrical applications. To summarize, the mechanical properties of aluminum sheets include a high strength-to-weight ratio, good formability, high corrosion resistance, excellent thermal conductivity, and good electrical conductivity. These properties make aluminum sheets the preferred choice for a wide range of applications across various industries.

Send your message to us

Industrial Aluminum Foil Sheets - Price for 5052 Aluminium Sheet/Aluminium Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords