Aluminum Sheets for Sale Kansas - Best Stocked Aluminum Sheets at Warehouse Prices

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Product Description

aluminum shees with cold rolled and hot rolled plate are widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 8000series, 7000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1100,3003, 3005, 3105, etc.

The temper is include H14, H22, H24, H44,O,H114,etc.

2. Main features of the product

a.Competitive price

b. Shortest service.

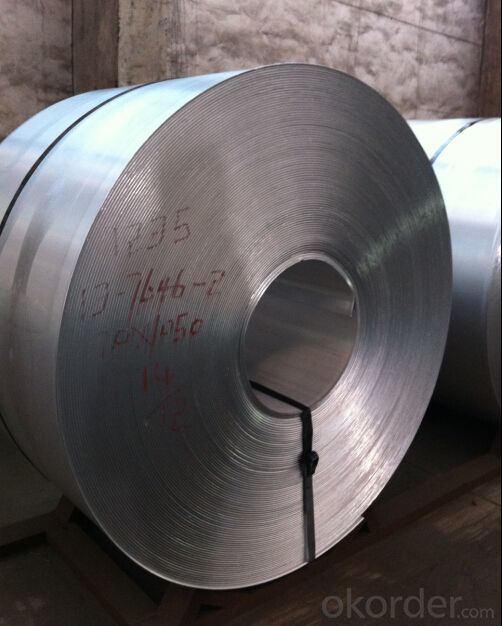

3. Image.

4. Product detailed sizes:

1000mm*2000mm,1000mm*2500mm,1250mm*2500mm,at random sizes,etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 6000mm, etc.

What is the MOQ for your products yet?

---Normally it is around 7 tons/each size.

How many tons did you export in one year

USA, Japan,UAE, Vietnam, Canada, etc.

What is your mainly products?

---Normally they are checkered aluminum sheet with big-5-bar and small-5-bar pattern,mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: Can aluminum be either conductive or magnitized?

- Aluminum can be conductive but not magnetized. In fact it has the ability to be a superconductor. But based on the electron spin in the last orbital it makes it Paramagnet. which means that it alone is not magnetic, but it will conform and be attracted to other magnetic fields. note that Al has such a low Paramagnetism that it will not be detectable with out sensitive equipment.

- Q: i need to know these things please....can aluminium withstand the forces of being in a cargo hold on a air freight, can it withstand extreme temps and to what extent an is it microwavable?? please help me

- No metals are microwavable, they will ruin any microwave oven by producing sparks. Even ceramic plates with a little metallic paint eg of silver will spark. Aluminium on its own has little strength but when mixed with small amounts of eg copper or manganese it aquires great strength while remaining light. In addition it has the advantage of being very resistant to oxidation and corrosion. It is certainly used extensively in aircraft construction. Due to being non toxic it used to make cans for beers, soft drinks (sodas) etc However it doesn't stand up well to high temperatures, its melting point is just at 660 degrees celsius, by comparison for iron it is 1540 and tungsten 3420.

- Q: Where does China make aluminum plate?

- In many parts of the country have aluminum factory, the old state-owned enterprises have 101, SWA aluminum plant, located in the southwest, northeast china. The emerging aluminum processing base in Henan, due to resource advantages, the largest aluminum factory, the price is relatively low.

- Q: Can 101 aluminum sheets be bonded to other materials?

- Yes, 101 aluminum sheets can be bonded to other materials. Aluminum can be bonded using various methods such as adhesive bonding, welding, or mechanical fastening techniques. The choice of bonding method depends on the specific materials being bonded and the desired strength and durability of the bond.

- Q: I've had a Champion bass boat forever, but today I bought an aluminum G3 boat that was so cheap I couldn't pass it up. The G3 is aluminum. What are the pros and cons?

- In general terms, you will get a smoother, quieter better ride from the fiberglass than the aluminum. The fiberglass is heavier and will ride a little deeper in the water. Obviuosly, the aluminum will bounce off rocks better than the glass, but we usually try to avoid those situations. Also, resale will most likely be better on the good glass boats.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Yes, aluminum sheets can definitely be an alternative to wood in certain applications. Aluminum has many advantages over wood, making it a popular choice in various industries. Firstly, aluminum is highly durable and long-lasting, as it is resistant to corrosion, rot, and pests. This makes it ideal for outdoor applications or areas with high moisture content. Additionally, aluminum sheets are lightweight, making them easier to handle and transport compared to wood. They also have high strength-to-weight ratio, meaning they can withstand heavy loads without compromising structural integrity. Furthermore, aluminum is a sustainable material as it can be recycled indefinitely without losing its properties. In contrast, wood requires cutting down trees, which has environmental implications. Aluminum sheets also offer design flexibility, as they can be easily shaped, bent, and formed into complex structures, allowing for creative and innovative applications. Moreover, aluminum has excellent thermal and electrical conductivity, making it suitable for applications where heat dissipation or electrical conductivity is important. Despite these advantages, it is important to note that wood still has its unique characteristics and benefits in certain applications. Wood creates a warm and natural aesthetic that aluminum cannot replicate, and it is often preferred in interior design or furniture manufacturing. Additionally, wood is a renewable resource and has excellent insulating properties, which can be advantageous in construction or insulation applications. Therefore, while aluminum sheets can be a great alternative to wood in many cases, the choice ultimately depends on the specific requirements and desired outcomes of the application.

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets can vary depending on the thickness of the sheet and the specific alloy being used. However, in general, a typical bend radius for aluminum sheets ranges from 0.8 to 2 times the thickness of the sheet.

- Q: Are aluminum sheets suitable for HVAC systems?

- Yes, aluminum sheets are suitable for HVAC systems. Aluminum is a lightweight and durable material that provides excellent thermal conductivity, making it ideal for use in HVAC systems. It is commonly used for making ductwork, heat exchangers, and fins in air conditioning units. Aluminum sheets are corrosion-resistant, which is advantageous in environments with high humidity or exposure to moisture. Additionally, aluminum is a recyclable material, making it an environmentally friendly choice for HVAC systems. Overall, aluminum sheets offer numerous benefits and are widely used in the HVAC industry.

- Q: what is the behaviour of Al2O3= aluminium oxide and SiO2= silicon dioxide when heated from room temperature to 1000 degree celcius?

- Aluminium oxide is a metal oxide and here shows it's basic properties. Silicon dioxide is a non metal oxide, so acidic Acid + base ---- salt so aluminium silicate is formed

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets are known for their excellent weather resistance properties. Due to their inherent corrosion resistance, aluminum sheets can withstand exposure to various weather conditions without deteriorating or rusting, making them highly suitable for outdoor applications. The protective oxide layer that naturally forms on the surface of aluminum provides a barrier against moisture, preventing the metal from reacting with oxygen and thus reducing the risk of corrosion. Additionally, aluminum sheets have high resistance to UV radiation, making them resistant to fading or discoloration caused by prolonged exposure to the sun. Overall, aluminum sheets offer exceptional performance in terms of weather resistance, making them a reliable choice for a wide range of outdoor applications, including roofing, siding, and outdoor signage.

Send your message to us

Aluminum Sheets for Sale Kansas - Best Stocked Aluminum Sheets at Warehouse Prices

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords