High Quality Aluminum Sheets for Curtain Wall Raleigh

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

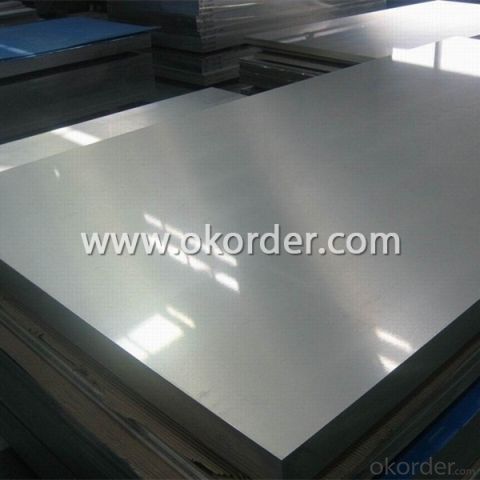

1.Structure of Aluminum Sheets for Curtain Wall with HIgh Quality

Our aluminum sheets are widely used in solar energy curtain wall. It integrates a photo-voltaic system. Photovoltaic panels are usually installed on the glass of curtain wall to generate electricity from solar energy.

Our aluminum sheets can meet the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

2.Main Features of Aluminum Sheets for Curtain Wall with HIgh Quality

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

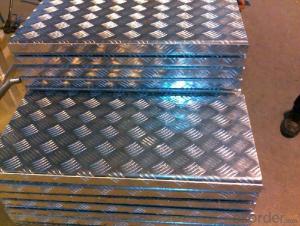

3. Aluminum Sheets for Curtain Wall with HIgh Quality Images

4.Specification of Aluminum Sheets for Curtain Wall with HIgh Quality

Alloy | AA1050,AA1060, AA1070, AA1100 |

Temper: | H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

Thickness: | 0.10-500mm |

Width: | 10mm- 2200mm |

Standard: | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement | |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum sheets be used for air conditioning systems?

- Indeed, air conditioning systems can make use of aluminum sheets. Due to its remarkable heat transfer properties, aluminum is widely employed in the fabrication of air conditioning systems. Its lightweight nature, resistance to corrosion, and exceptional thermal conductivity render it a perfect material for producing coils, fins, and heat exchangers within air conditioning units. Furthermore, aluminum sheets can be effortlessly manipulated and molded into diverse forms and dimensions, thereby enabling flexibility in both design and installation.

- Q: How do you prevent distortion of aluminum sheets during welding?

- To prevent distortion during the welding of aluminum sheets, there are several important steps that can be taken: 1. It is crucial to properly prepare the joint by cleaning and beveling the edges of the aluminum sheets. This will ensure a better fit-up and reduce the likelihood of distortion. 2. The use of appropriate fixtures and clamps to hold the aluminum sheets in place during welding can help distribute the heat evenly and prevent movement or buckling. This will minimize the risk of distortion caused by thermal expansion. 3. Tack welding can be done at regular intervals along the joint before performing a full weld. This temporarily secures the sheets and allows for controlled cooling, reducing distortion. 4. Following a proper welding sequence is also beneficial. Starting from the center and gradually moving towards the edges, alternating between sides, helps balance the heat input and allows for cooling between welds, minimizing distortion. 5. Preheating the material before welding can help reduce the temperature gradient and minimize distortion for thicker aluminum sheets. Post-weld heat treatment can also be applied to relieve residual stresses and promote dimensional stability. 6. Employing appropriate welding techniques, such as lowering the heat input and using a slower travel speed, can help minimize distortion. Using a smaller weld bead size and avoiding excessive weaving also control the heat input and reduce distortion. 7. It is crucial to ensure that the welding parameters, such as voltage, current, and wire feed speed, are correctly set and maintained. Using the appropriate parameters for the specific aluminum alloy being welded will result in a more controlled heat input, reducing distortion. By implementing these preventive measures, the risk of distortion during aluminum sheet welding can be significantly reduced, leading to improved weld quality and dimensional stability.

- Q: What is the width and length of the aluminum sheets?

- Depending on the specific product or manufacturer, the aluminum sheets' width and length may differ. To obtain accurate measurements, it is advisable to consult the product specifications or get in touch with the manufacturer.

- Q: or aluminum ? and what other gases are released?

- Aluminium does not normally react with water because of a surface coating of the highly unreactive Al2O3 that forms on exposure to atmospheric oxygen. In the presence of strong base, however, this compound dissolves due to complexation by hydroxide, similarly to how silver chloride dissolves in ammonia. Al2O3(s) + 2OH-(aq) + 3H2O(l) ----- 2[Al(OH)4]-(aq) Once this has occured, aluminium metal, a very strong reducing agent, is exposed to water. 2Al(s) + 6H+(aq) ----- 2Al3+(aq) + 3H2(g) Even though the solution is alkaline, there is still a low concentration of H+ formed by the autoprotolytic dissociation of water. The Al3+ formed then reacts with hydroxide to produce more [Al(OH)4]-. Yes, the hydrogen gas is from the water.

- Q: What is the fire rating of 101 aluminum sheets?

- The fire rating of 101 aluminum sheets is typically classified as Class A, indicating a high level of fire resistance.

- Q: just bought a hobart handler 140 (already love it), and was just wondering on what gas to use for aluminum. my welder will be set up for mild steel (75% argon 25% CO2). it would be nice to be able to use this mix with aluminum as well, as it would be easy to just switch spools of wire, but the manual says to use a 100% argon mix when welding with aluminum. will the 25% CO2 make a difference welding aluminum?

- Get the kit which will have new drive wheels and the liner, and get the right gas, and don't plan on using any thin aluminum, I was never able to have fine enough control on my machine to get it to work well on anything less than 1/8 material. Also, you will probably buildup too much heat and burn through if you try to go far, weld about 1 at a time and let the material cool. Your machine and mine are just barely on the edge of being capable of doing this. It is nearly impossible to dial it in to a reliable point.

- Q: Can aluminum sheet be used in marine environments?

- Certainly, aluminum sheet finds utility in marine environments. The corrosion resistance exhibited by aluminum renders it a favored material for marine purposes. The formation of a safeguarding oxide layer on its exterior effectively curbs corrosion, even in the presence of saltwater. Moreover, aluminum's lightweight nature qualifies it as an optimal selection for marine applications where weight reduction is paramount. Given its robustness, strength, and corrosion resistance, aluminum sheet is extensively employed in boat hulls, decks, and various other marine constructions.

- Q: Can aluminum sheets be used in automotive applications?

- Yes, aluminum sheets can be used in automotive applications. Aluminum is a lightweight and durable material that offers a variety of benefits for automotive manufacturing. It is commonly used in the production of car bodies, hoods, doors, roofs, and other components. The use of aluminum sheets in automotive applications helps to reduce the overall weight of the vehicle, which improves fuel efficiency and performance. Additionally, aluminum has excellent corrosion resistance properties, making it ideal for withstanding harsh weather conditions and road salt exposure. Furthermore, aluminum can be easily formed and shaped, allowing for complex designs and intricate detailing on automotive parts. Overall, the use of aluminum sheets in automotive applications contributes to the production of lighter, more fuel-efficient, and aesthetically appealing vehicles.

- Q: Can the aluminum sheets be used for printing applications?

- Yes, aluminum sheets can be used for printing applications. Aluminum provides a smooth and flat surface, making it ideal for printing graphics, images, and text. The sheets can be easily printed on using various printing methods such as offset printing, screen printing, and digital printing. Printing on aluminum sheets offers durability, resistance to fading and weathering, and a professional and sleek appearance. It is commonly used for signage, labels, nameplates, and decorative purposes in industries like advertising, automotive, aerospace, and packaging.

- Q: Can aluminum sheets be used for elevator interiors?

- Yes, aluminum sheets can be used for elevator interiors. Aluminum is a popular material choice for elevator interiors due to its various advantageous properties. It is lightweight, durable, and resistant to corrosion, making it suitable for long-term use in elevator applications. Aluminum sheets can be easily fabricated and shaped to fit the dimensions and design requirements of elevator interiors. Additionally, aluminum can be finished with different types of coatings or finishes, such as anodizing or powder coating, to enhance its appearance and provide additional protection. Overall, aluminum sheets are a viable option for elevator interiors and are commonly used in the industry.

Send your message to us

High Quality Aluminum Sheets for Curtain Wall Raleigh

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords