Tlc Aluminum Sheets Si60 F254 for Aluminium Tile Trim Profile Windows and Doors Construction Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Tile Trim Profile windows and Doors Construction Usage Description:

Aluminium Tile Trim Profile windows and Doors Construction Usage (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Tile Trim Profile windows and Doors Construction Usage:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

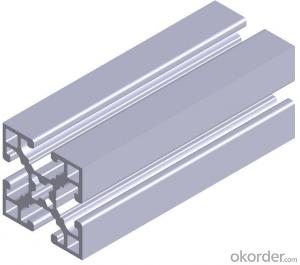

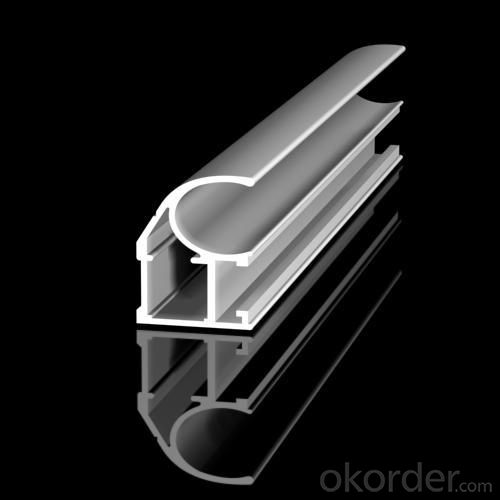

3.Aluminium Tile Trim Profile windows and Doors Construction Usage Images:

4.Aluminium Tile Trim Profile windows and Doors Construction Usage Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is it possible to utilize recycled aluminum scraps as an alternative to purchasing new aluminum sheets for a project?

- <p>Yes, you can use recycled aluminum scraps in your project instead of buying new aluminum sheets. Recycled aluminum is not only environmentally friendly but also cost-effective. It has similar properties to new aluminum, making it suitable for many applications. However, ensure the quality and purity of the recycled aluminum meet your project's requirements. Check for any impurities or inconsistencies that might affect the strength or performance of your final product. If the recycled aluminum is in good condition and appropriate for your needs, it can be a sustainable and economical choice.</p>

- Q: What kind of material is 2A12 aluminum sheet?

- 2A12 is a typical Al Mg alloy in Al Cu mg system. Its composition is reasonable and its comprehensive properties are better. Many countries produce this alloy, which is the largest in use. The alloy is characterized by high strength, a certain heat resistance, and can be used as working parts below 150 degrees C.

- Q: hi my house is wired with aluminum wire and we have this light that has been changed 6 times because originally there was a cheap builders light up there that got replaced with a ceiling fan but the ceiling fan was replaced a couple of times since the remote never worked properly on any of the cieling fans so finally we replaced the cieling fan with just a normal light but now the socket got cracked on the new light by accident. The problem is im wondering if it is safe to put another light up because i have heard aluminum wire breaks easy and the wires have been moved around alot. But if i dont replace the light i wont have a light. We also use the correct wire nuts and anti oxidant on the connections. Also when the 4 cieling fans that had been put up were wired correctly since i have put up many cieling fans up without remotes before. Also Is there a certain number of times aluminum or copper wire can be bent with out having to worry about a fire happening or the wire breaking.

- You can never ever connect an Aluminum wire to a Copper wire. Never, copper in contact with aluminum and a bit of moisture acts like a Battery. Remember the old Grade School experiment where students made a battery using copper pennies and aluminum foil by simply contacting the foil to several pennies, then lighting a neon bulb! So copper in contact with aluminum creates a galvanic action due to potential difference and thus can cause a hot spot and a fire can literally break out in the junction box where you made the connection. Keep this always in mind since you have a whole house of that aluminum wire. To connect aluminum wire to a fixture you need a fixture that will accept an aluminum wire. Check that with the hardware or where or Lowes or wherever you buy the fixture from. There are fixtues with contacts points for wire in them that accept both copper and aluminum wire. So you do not need to replace the wire just to install the fixture. Or you can go to Lowes and get a special connector that safely connects the aluminum wire to a short piece of copper wire and then connect that copper pigtail piece to any fixture you buy. The danger of aluminum wire has never been that becomes brittle, but that corrosion forms at screw joints in the switches, outlet boxes and the like, that causing a resistance and that resistance acting literally like a heater and becoming red hot and starting a fire.

- Q: Maybe you didn't know but in the year 2025 the earth's population will be up to 12 billion people, which is double what we have now. And i am doing a project on Aluminum, and I have to know if there is enough AL for this many people in the year 2025. So will there be enough AL in the world to support us all?

- Aluminium is the third most abundant element on earth after oxygen and silicon. I am quite sure that we will not run out of aluminium in the future. Oxygen - or at least pure good quality oxygen - is probably a more worrying scenario.

- Q: Can the aluminum sheets be used for manufacturing heat shields?

- Yes, aluminum sheets can be used for manufacturing heat shields. Aluminum is known for its excellent thermal conductivity and high heat resistance. It is commonly used in various industries, including automotive and aerospace, for manufacturing heat shields. Aluminum sheets can effectively reflect and dissipate heat, making them an ideal material for this purpose. Additionally, aluminum is lightweight and corrosion-resistant, making it a practical choice for heat shield manufacturing.

- Q: Can the aluminum sheets be used for manufacturing food storage containers?

- Yes, aluminum sheets can be used for manufacturing food storage containers. Aluminum is a highly suitable material for food storage due to its non-toxic properties, excellent heat conductivity, and resistance to corrosion.

- Q: How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q: Are 101 aluminum sheets available in different finishes (e.g., brushed, polished)?

- There are different finishes available for 101 aluminum sheets, including brushed and polished. These finishes are obtained using various methods that create distinct textures and appearances on the surface of the sheets. To achieve a brushed finish, the sheet is brushed with an abrasive material, resulting in a pattern of fine lines. This finish is commonly used to give the sheet a matte look. On the other hand, a polished finish is achieved by polishing the sheet to create a high shine. This finish is often chosen to create a smooth and reflective surface. Therefore, depending on the desired aesthetic or functional requirements, one can opt for either a brushed or polished finish for 101 aluminum sheets.

- Q: I know 7005 series aluminum is stronger and lighter than 6061series, but how does 7005 compare to 2014 series?

- This okorder /.... Aluminum is a very different animal than steel, so the choice of alloy depends on what the application is. For instance, 7075-T6 is the most common high-end alloy for chainrings, but it has comparatively low tensile and yeild strengths.....and yet it's the most durable choice for the application. Chainrings made out of a stronger alloy won't last as long and may develop stress cracks. Some of the alloy choices depend upon machining and welding characteristics, too...it's not always about the strongest or lightest. You wouldn't want a part like a seatpost to be made of the material with the best numbers but that has a tendency to crack after welding.

- Q: Can the aluminum sheets be custom-cut to specific dimensions?

- Indeed, it is possible to have aluminum sheets custom-cut to specific dimensions. Aluminum, being a material of great versatility, can be easily manipulated to achieve precise cuts that meet particular requirements. Whether for industrial, commercial, or personal purposes, aluminum sheets can be tailored to the exact dimensions desired, guaranteeing a flawless fit for any undertaking. This option for customization offers enhanced flexibility, enabling the aluminum sheets to be utilized in a multitude of applications.

Send your message to us

Tlc Aluminum Sheets Si60 F254 for Aluminium Tile Trim Profile Windows and Doors Construction Usage

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords