125 Aluminum Diamond Plate Sheets - 1060 C.C Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Aluminum Sheets 1060 C.C Quality Description

Aluminum sheets 1060 C.C quality is cut from aluminum coils 1xxx. The aluminum content of aluminum sheets 1xxx C.C quality is 99% at least. It has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum sheets 1060 C.C quality is widely used for electronics, instruments, lighting decoration, packing industry, house decoration, curtain wall, honeycomb-core panel, sandwich panel, aluminum composite panel and aluminum composite pipes.

2.Main Features of the Aluminum Sheets 1060 C.C Quality

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

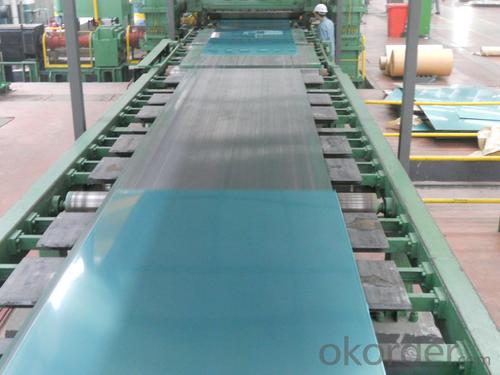

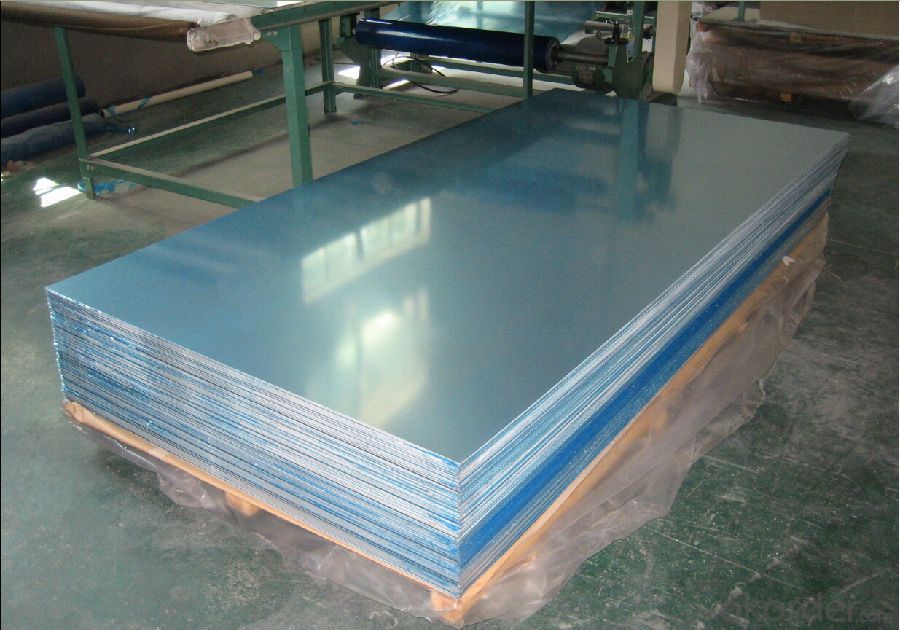

3. Aluminum Sheets 1060 C.C Quality Images

4. Aluminum Sheets 1060 C.C Quality Specification

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc. |

Temper | H14, H16, H18, H22, H24, H26, H32, O/F |

Thickness | 0.2mm -- 100mm |

Width | 30mm -- 1700mm |

Standard | GB/T 3880-2006,EN,ASTM,JIS |

5. FAQ of Aluminum Sheets 1060 C.C Quality

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test the aluminum sheets 1060 C.C quality products.

B.When will you deliver the products?

The aluminum aluminum sheets 1060 C.C quality will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: What are the different methods of joining aluminum sheets?

- There are several methods of joining aluminum sheets, including welding, adhesive bonding, mechanical fastening (such as riveting or screwing), and clinching. Each method has its own advantages and considerations, depending on the specific application and desired outcome.

- Q: Can aluminum sheets be anodized with custom colors?

- Custom colors can indeed be applied to aluminum sheets through the process of anodizing. Anodizing involves the application of an electrochemical procedure that adds a protective oxide layer to the aluminum's surface, thereby enhancing its durability and resistance to corrosion. In this process, the aluminum sheet is submerged in an electrolytic solution while an electrical current is passed through it. This induces a controlled oxidation of the aluminum's surface, leading to the formation of a porous layer that can be colored with dyes to achieve desired shades and hues. By carefully selecting the appropriate dye, a wide array of custom color options can be achieved. Moreover, anodized aluminum sheets offer versatility as they can undergo additional treatments like laser engraving or printing to create distinctive designs and patterns. Therefore, they are highly suitable for a diverse range of applications in industries such as architecture, automotive, and electronics.

- Q: I need some aluminum sheets for an art project. I'm not sure where to find such a thing, though. I've looked at Home Depot briefly and aluminum flashing is the closest thing I've found. Flashing comes in a roll and is just a bit too thin. I need flat sheets of aluminum that are somewhat stiff, but not more than, say, 1/4 thick. Are there any stores that sell such things? A larger sheet would be fine if I could either get it cut at the store or find some way to cut it to the size I want. How do you cut aluminum, anyway? Any suggestions are greatly appreciated!

- Sign industry suppliers sell aluminum blanks. try this If you are in a different area of the planet, google aluminum sign blanks. Aluminum can be cut with a metal blade in a jigsaw.

- Q: Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance properties and lightweight nature. It can withstand the harsh conditions of saltwater, making it suitable for boat building, marine structures, and other marine-related uses.

- Q: Excuse me: what kind of aluminum sheet is the cheapest? Which materials are more expensive?

- According to the general arrangement from low to high prices:The first 1 lines are the cheapest, such as 1050.1060.1070..1100, which is pure aluminum;Second, 3 Department prices, such as 3003.3004.3104, etc..

- Q: Are aluminum sheets suitable for chemical processing?

- Yes, aluminum sheets are suitable for chemical processing due to their excellent corrosion resistance, high thermal conductivity, and lightweight properties. They can be effectively used for various chemical applications such as containers, piping, and heat exchangers.

- Q: Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is widely used in the aviation industry due to its excellent strength-to-weight ratio, which makes it ideal for constructing lightweight yet strong aircraft structures. Aluminum sheets are commonly used for aircraft panels because they offer a combination of durability, corrosion resistance, and ease of fabrication. Additionally, aluminum can be easily formed and welded, allowing for complex panel shapes to be created. Furthermore, aluminum has good electrical conductivity, which is important for the proper functioning of various aircraft systems. Overall, the use of aluminum sheets for aircraft panels helps to ensure the structural integrity and performance of the aircraft.

- Q: Can the aluminum sheets be used for reflector applications?

- Yes, aluminum sheets can be used for reflector applications. Aluminum is widely known for its high reflectivity, making it an ideal material for reflectors in various industries. It has a reflectivity of around 90% for visible light and up to 95% for infrared radiation. The smooth surface of aluminum sheets allows for efficient reflection of light and heat, making them suitable for applications such as automotive headlights, solar reflectors, lighting fixtures, and optical instruments. Additionally, aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity, further enhancing its suitability for reflector applications.

- Q: 1995 s10 I took this whole thing apart and marked and labled everything. Now i have an aluminum head sitting on a bucket that was spraying water right from the head gasket but the head gasket is in perfect shape, and there are no cracks i can see on the head. One more thing, the truck would not start up with water in it, but it would when it was drained, like it was blocking the spark or something. yes it did overheat has this ever happened to anyone else, and any ideas? Thank you.

- Could be 1 of 5 things Blown intake gasket Blown head gasket Cracked head Cracked block Warped head. Most of the times you will not see a crack with your eyes. The head needs to be magnafluced or pressure tested to see if theres a crack. Check your phone book for machine shops. An engine machine shop will check a head for cracks for around $20-40 per head To check if its Warper you can do that with a true flat, straight edge like a long steel rule, and a feeler gauge. Lay rule on bottom of head where gasket goes (all traces of old gasket cleaned off 1st), Try to slide a .001 feeler gauge under rule. If warped a machine shop can mill head flat for around $35-50 per head

- Q: What are the aluminum plates for?

- Defense (cover containing polyethylene moistureproof layer of kraft paper embossing aluminum alloy), special mould. The tensile aluminum alloy aluminum coated aluminum. Special stamping. Electronic gasket aluminum, alloy aluminum alloy electric radiator. Special aluminum curtain wall coating. (fluorocarbon, polyester) aluminum coil, aluminum coil, special signs aluminum plate, color coated aluminum sheet, aluminum ceiling coating, aluminum plate, aluminum plate pattern, embossing aluminum / aluminum (pointer type, orange peel pattern, diamond, five ribs, aluminum strip). Aluminum wire and cable, transformer Using aluminum strip, aluminum foil, pressure type aluminum corrugated corrugated aluminum plate. Color coating, special aluminum plate, aluminum plate cable tray, material: 1100.1200.1050A.1060.1070.1080.1145.2A11.3003.3A21.3004.3005.3104.3105.LF21.5A02.5A05.5005.5754.5052.5083.5082.5A03.6061.6063.6082.8011. material; H111.H112.H18.H26.H16.H22.H32.H34.H36.H14.H24.H12.T4.T5.T6.O.F state can meet the requirements of customers

Send your message to us

125 Aluminum Diamond Plate Sheets - 1060 C.C Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords