Everlast Aluminum Indoor Decorative Sheet Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

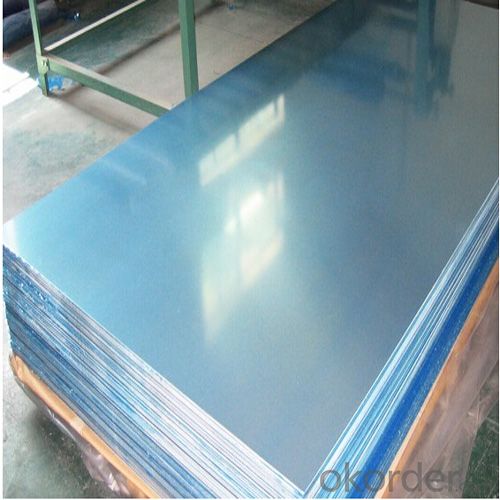

1.Structure of Aluminum Sheet Plate for Indoor Decoration Description:

We can produce aluminum sheet,color aluminum sheet and plastic composite panel base material. They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Aluminum Sheet Plate for Indoor Decoration :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

3. Aluminum Sheet Plate for Indoor Decoration Images:

4. Aluminum Sheet Plate for Indoor Decoration Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: This question asks for the steps to take in order to accurately measure the dimensions of an aluminum sheet before purchasing one.

- <p>To measure the dimensions of an aluminum sheet for purchase, first, ensure you have a measuring tape or a ruler. Measure the length and width of the sheet from one corner to the opposite corner, making sure to measure along the longest and widest sides. Record these measurements in the same unit of measurement used by the supplier (commonly inches or centimeters). If the sheet is not a perfect rectangle, measure the diagonal to confirm the dimensions. Note any irregularities or variations in thickness that might affect the intended use. Once you have these measurements, compare them with the available options from the supplier to select the appropriate size.</p>

- Q: Explain how aluminum sheets impact the soundproofing capabilities of a building.

- <p>Aluminum sheets can have a significant impact on the sound insulation of a building. They are often used as a cladding material due to their durability and low maintenance requirements. However, aluminum is a good conductor of sound, which means it can transmit sound waves efficiently. This can reduce the sound insulation of a building, especially if the aluminum sheets are not combined with other soundproofing materials. To improve sound insulation, aluminum sheets can be combined with insulation materials, such as polyurethane foam, to create a barrier that reduces sound transmission. Additionally, using thicker aluminum sheets or adding a layer of sound-absorbing material can help enhance the soundproofing capabilities of a building.</p>

- Q: Is it possible to use aluminum sheets as a material for interior wall decoration?

- <p>Yes, aluminum sheets can be used for interior wall cladding. They are lightweight, durable, and resistant to corrosion, making them suitable for various interior applications. Aluminum sheets are also easy to install and maintain, and they can be painted or finished in various ways to match different design styles. However, it's important to ensure proper installation and adherence to local building codes and regulations.</p>

- Q: What is the tensile strength of 101 aluminum sheets?

- The tensile strength of 101 aluminum sheets varies depending on the thickness and manufacturing process, but it typically ranges from 20,000 to 30,000 pounds per square inch (PSI).

- Q: what is better for my 96 mustang gt. porting and polishing my stock heads or getting aluminum heads. also could i do a 3v conversion?

- Your car already has aluminum heads on it. I'm not sure if the 3v heads bolt on and if they did they would expensive. Porting and polishing is not easy and often very expensive. A lot of people do more harm than good. This is not a Gran Turismo game where you click a button. If I were you this is what I would do. 96-98 4.6 heads suck, bottom line. Your car put out 215 HP stock. In 99 Ford starting using what is called the PI head. The horsepower went up to 260 mainly because of the better heads. Search on OKordermotors or look at Ford Racing Parts, they sell the heads brand new for $375 a piece I think plus the intake for around $200. They will do much better than porting your heads and probably cost less too. If you really want to get them ported or get ported heads look into Patriot Peformance, they sell 4.6 heads already ported. Good luck.

- Q: This question asks about the influence of aluminum sheets on the thermal insulation properties of a building.

- <p>Aluminum sheets, due to their high thermal conductivity, can actually reduce the insulation of a building if not properly used. They can conduct heat quickly, which means that they may transfer heat from the outside to the inside or vice versa, depending on the temperature difference. This can lead to increased energy consumption for heating or cooling. However, when used as a reflective barrier in combination with proper insulation materials, aluminum sheets can help reflect heat and improve insulation by reducing heat transfer. It's crucial to use aluminum sheets correctly and in conjunction with other insulating materials to achieve optimal thermal performance in buildings.</p>

- Q: Are aluminum sheets suitable for medical equipment?

- Yes, aluminum sheets are suitable for medical equipment. They are lightweight, durable, and have high corrosion resistance, making them ideal for various medical applications such as surgical instruments, diagnostic equipment, and prosthetics.

- Q: Can aluminum sheets be used for signage purposes?

- Yes, aluminum sheets can be used for signage purposes. They are commonly chosen for outdoor signs due to their durability, weather resistance, and lightweight nature. Aluminum sheets can be easily customized, printed on, and shaped to create professional and long-lasting signage.

- Q: What are the different types of alloys used for powder-coated aluminum sheets?

- Powder-coated aluminum sheets utilize various alloys, each possessing distinct properties and characteristics. Among the commonly utilized alloys are: 1. The 3003 Alloy: This alloy finds extensive application in powder-coated aluminum sheets due to its exceptional corrosion resistance, formability, and high strength. Its versatility makes it suitable for building facades, signage, and automotive parts, where moderate strength and resistance to atmospheric corrosion are essential. 2. The 5052 Alloy: Renowned for its remarkable strength and excellent corrosion resistance, this alloy is commonly employed in marine and architectural applications that demand durability and resistance to saltwater and harsh environments. Additionally, it is frequently used for manufacturing electrical enclosures and transportation equipment. 3. The 6061 Alloy: This highly versatile alloy offers outstanding weldability, formability, and machinability. It finds application in various fields, including aerospace components, marine hardware, structural components, and automotive parts. Its corrosion resistance allows for easy powder coating, enhancing appearance and providing additional protection. 4. The 7075 Alloy: Noted for its exceptional strength-to-weight ratio and fatigue resistance, this alloy is predominantly utilized in aerospace applications, such as aircraft fittings and structural components, where strength and lightweight properties are crucial. Although its higher cost limits its use in powder-coated aluminum sheets, it remains present in specific specialized applications. These examples represent only a fraction of the diverse range of alloys employed in powder-coated aluminum sheets. The selection of an alloy depends on specific application requirements, encompassing factors such as strength, corrosion resistance, formability, and cost.

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- Polished aluminum, get a couple heavy duty buffers and some for your friends and then buy stock in Flitz. You can also get it where you want it and paint it with clearcote to keep it a littl better, or what most do; paint it a light gray or silver color. You can strip it, but strip and paint is not cheap. Also, since the controls are fabric covered, they will never match the polished fuselage, that's why paint is better.

Send your message to us

Everlast Aluminum Indoor Decorative Sheet Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords