Extruded Aluminum Ribbed Sheets 1050 3003 1.2mm to 3mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCTS ADVANTAGE:

1: Thousands of already-made extrusion moulds are free for customer;

2: Any surface treatment is acceptable to make to meet your needs;

3: Strict quality control for your goods, very little scratch;

4: Free surface and both edges of profiles are smooth and with no burr;

5: Standard alloy composition;

PRODUCTS CHEMICAL COMPOSITION:

| Alloy | Chemical Composition % | ||||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | ||

| Single | Tol | ||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.6 |

| 2011 | 0.4 | 0.7 | 5.0-6.0 | - | - | - | 0.3 | - | 0.05 | 0.15 | Remain |

| 2014 | 0.5-1.2 | 0.7 | 3.9-5.0 | 0.4-1.2 | 0.2-0.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | 0.1 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 3003 | 0.6 | 0.7 | 0.05-0.2 | 1.0-1.5 | - | - | 0.1 | - | 0.05 | 0.15 | Remain |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2-2.8 | 0.15-0.35 | 0.1 | - | 0.05 | 0.15 | Remain |

| 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | - | 0.15 | 0.1 | 0.05 | 0.15 | Remain |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.04-0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Remain |

| 6063 | 0.38-0.43 | 0-0.25 | 0.1 | 0.1 | 0.5-0.6 | 0.1 | 0.1 | 0.1 | 0.05 | 0.15 | Remain |

| 6082 | 0.7-1.3 | 0.5 | 0.1 | 0.41 | 0.6-1.2 | 0.25 | 0.2 | 0.1 | 0.05 | 0.15 | Remain |

| 6463 | 0.2-0.6 | 0.15 | 0.2 | 0.05 | 0.45-0.9 | - | 0.05 | - | 0.05 | 0.15 | Remain |

| 7003 | 0.3 | 0.35 | 0.2 | 0.3 | 0.51 | 0.2 | 5.0-6.5 | 0.2 | 0.05 | 0.15 | Remain |

| 7005 | 0.35 | 0.4 | 0.1 | 0.2-0.7 | 1.0-1.8 | 0.06-0.2 | 4.0-5.0 | 0.01-0.06 | 0.05 | 0.15 | Remain |

| 7075 | 0.4 | 0.5 | 1.2-2.0 | 0.3 | 2.1-2.9 | 0.18-0.28 | 5.1-6.1 | 0.2 | 0.05 | 0.15 | Remain |

PRODUCTS DETAIL:

| Brand name | Bengal Aluminum |

| Aluminum products | Aluminum profile,Thermal break profile,Aluminum bar,Aluminum tube/pipe, Aluminum sheet,Aluminum heat sink section,Aluminum curtain wall,Aluminum handle,Aluminum frame,Aluminum rail,Aluminum accessory |

| Thickness | Mill finish profile thickness:0.7mm-3mm |

| Anodizing film thickness:over13μ | |

| Power coating film thickness:over13μ | |

| Length | General length:0-6m |

| Meet customers requirement | |

| Shape | Round,Flat,Square,Oval,Triangle,Pentagon, Hexagon,T,L, or customized requirement available |

| Surface treatment | Powder coating,Anodizing,Sand blasting, wood grain,electrophoresis, polishing,PVDF,etc |

| Deep process | CNC,Drilling,Milling,Bending,Cutting,Welding,etc |

| Colour | Silver, bronze,Black,Champagne,gold,White,Grey,Green,etc |

| Temper | T3-T8, O-H112 |

| Application | Windows and doors frame,Curtain wall,Furniture,Kitchen cabinet door,LED light,ceiling,machine,fences,Construction,Industrial,etc |

| Lead time | 8-20 days after the sample is confirmed by buyer |

| Mould fees | Free of charge if use existing mould |

| Charged by the size if open up a new mould | |

| Packing details | Packed with plastic protective film to protect each piece inside |

| Wrap to be bundles by waterproof craft paper | |

Packing ways depend on the profile goods design, we can meet customized requirement |

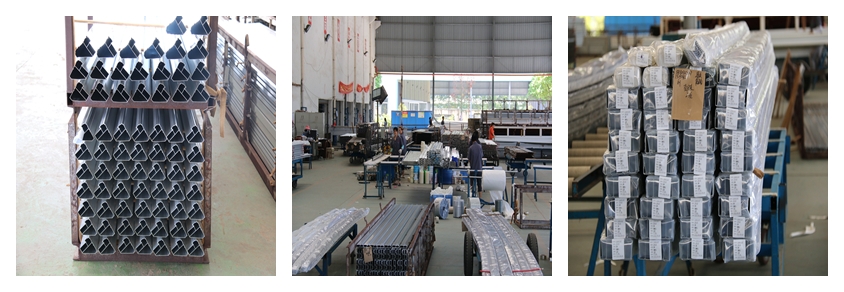

PACKAGING AND SHIPPING:

Your aluminum extrusion profile goods are always packaged to ensure that thay arrive safely on their long journey to you. The best packaging solutions depend on the design.We provide our customers with clear packaging consuting services. Normally, the products will be packed with plastic protective film to protect each piece inside and wrap to be bundles by waterproof craft paper outside.

Our Services

Onsite Factory Services | Onsite Factory Services |

|

|

We factory also provides the following services:

Engineering design

Research and development

Design consulting

Photos

- Q: Can anyone tell me what to be careful of if you have aluminum wiring in your house. I was told that if the wall gets hot, I need to tighten the screws of the inside switch. Is this true and if I didn't, would it actually cause a fire in the wall. If this is true, how often does it loosen?

- There are several ways to take care of your problem. 1) Change all the wiring to copper. 2) Pigtail with copper wire and al/cu wirenuts to all new devices 3) Use copalum at all your boxes (this method is the best, besides replacing all your wiring to copper). Basically it cold welds the aluminum to the copper and makes a molecular bond. It's pretty expensive, and you'll have to look to find someone that actually knows how to do it, and has access to the crimping tool. Going around and tightening your devices won't hurt, but won't be fixing any longer term issues you may have with the aluminum wire. Keep in mind that if the original installation was done correctly, your circuits aren't overly tapped, and all the wires are on the appropriately sized breakers, then you may not have to worry much. Just run dedicated lines to any your new circuits. In other words, don't tap off these circuits. Hope this helps.

- Q: What is the bending radius for aluminum sheets?

- The bending radius of aluminum sheets may vary depending on the sheet's thickness and alloy. In general, thinner sheets (around 1-3 mm) should have a bending radius of approximately 1.5 times their thickness. On the other hand, thicker sheets (over 3 mm) can increase the bending radius to around 2.5 times their thickness. Nevertheless, it's important to bear in mind that these are general guidelines and the bending radius may need to be adjusted according to the specific application and desired outcome. To obtain accurate bending radius information, it is always recommended to seek advice from a professional or consult the manufacturer's technical data sheets.

- Q: What is the coefficient of thermal expansion of aluminum sheets?

- The coefficient of thermal expansion of aluminum sheets differs based on the specific alloy employed. On average, aluminum exhibits a coefficient of thermal expansion of around 22 x 10^-6 per degree Celsius (22 x 10^-6/°C). Consequently, with each degree rise in temperature, the aluminum sheet will expand by 22 x 10^-6 times its original size. It should be emphasized that this figure might vary slightly among diverse grades and alloys of aluminum.

- Q: Does aluminum sheet require special handling during transportation?

- Transporting aluminum sheets requires special handling due to their lightweight nature and susceptibility to damage if mishandled. To prevent scratching, bending, or denting, it is necessary to take specific precautions. Packaging and securing the sheets in a manner that restricts movement and offers sufficient protection against impacts is crucial. Furthermore, it is important to transport aluminum sheets separately from heavy objects or materials to avoid potential damage caused by their weight. In conclusion, ensuring the safe transportation of aluminum sheets necessitates giving them special care and attention.

- Q: This question asks if aluminum sheets can be utilized for both exterior and interior purposes.

- <p>Yes, aluminum sheets can be used for both exterior and interior applications. They are popular for exterior use due to their durability, resistance to weather, and low maintenance requirements. For interior applications, aluminum sheets are valued for their lightweight, easy installation, and aesthetic appeal. They are commonly used in construction, automotive, and aerospace industries, among others. However, it's important to note that specific treatments or coatings may be necessary to enhance their performance in different environments.</p>

- Q: What are the dimensions of standard aluminum sheets?

- Aluminum sheets usually measure 4 feet by 8 feet as a standard. Nevertheless, it is essential to acknowledge the availability of aluminum sheets in diverse thicknesses, spanning from thin gauge sheets to thicker plates. The thickness of standard aluminum sheets can fluctuate from 0.025 inches to 0.25 inches or even greater. Moreover, aluminum sheets can be tailored and adjusted to distinct sizes and shapes according to specific project prerequisites.

- Q: Cooks are warned not to use aluminum cookware when preparing acidic foods. Why?

- Plain okorder /... Hope this helps.

- Q: What are the safety standards for aluminum sheets utilized in construction?

- <p>Yes, there are safety standards for aluminum sheets used in construction. These standards ensure the material's quality, strength, and suitability for various applications. They include specifications for thickness, alloy type, and surface treatment. International standards such as ASTM B209 (for aluminum sheet and plate) and EN 485 (for aluminum and aluminum alloy sheets) govern the production and use of aluminum sheets in construction. Compliance with these standards is crucial for safety, durability, and to meet regulatory requirements in different regions.</p>

- Q: What are the different methods of polishing aluminum sheets?

- Polishing aluminum sheets can be done through various methods, each with its own pros and cons. Here are some commonly used techniques: 1. Manual polishing: By employing sandpaper or abrasive pads, one can manually rub the surface of the aluminum sheet to achieve a high level of shine and smoothness. However, this method demands physical effort and can be time-consuming, especially for larger sheets. Careful execution is crucial to avoid leaving behind scratches or marks. 2. Chemical polishing: Dissolving a thin layer of the aluminum surface using chemical compounds can result in a smoother and shinier finish. This method is suitable for larger sheets or complex shapes where manual polishing is impractical. However, chemical handling must be meticulous, and it may not be suitable for certain aluminum alloys. 3. Electropolishing: An electrochemical process involving the use of an electric current to remove a thin layer of material from the aluminum surface. This method guarantees a smooth and shiny finish for both small and large sheets. It is particularly effective in eliminating surface imperfections and achieving a uniform appearance. However, specialized equipment and expertise are required to properly control the process. 4. Vibratory finishing: Placing aluminum sheets in a vibratory machine with abrasive media, like ceramic or plastic chips, can help remove surface imperfections and achieve a polished finish. This method is ideal for large batches of sheets and can be cost-effective. Nevertheless, it may not produce the same level of shine as other methods. 5. Buffing and polishing compounds: These compounds are applied to the aluminum sheets and then buffed using a rotary tool or polishing machine. The abrasive particles in the compounds aid in removing scratches and enhancing the metal's shine. This method is relatively quick and easy, but it may not be as effective for significant oxidation or deep scratches. Ultimately, the choice of polishing method depends on factors such as the size and type of the aluminum sheets, desired level of shine, and available equipment and expertise. It is advisable to test different methods on a small area before proceeding with the full polishing process to ensure satisfactory results.

- Q: I bought a house with aluminum wiring. Its about 1600 square feet. I have not had any problems with the electric but I read all these story's about how terrible aluminum wiring is.. is it worth the cost to replace? Most houses on my street have it also.. they have had no problems.. house was built in 79.How much would it cost to replace? would walls have to come down to do it?

- It has loosing joints problem between aluminum wire and copper screw joint. Some house caught fire happen on the wall outlet or power panel box. All the joints must use aluminum screw to join aluminum wire. Join copper with aluminum,the joint creates thermo-effect and heat builds up.

Send your message to us

Extruded Aluminum Ribbed Sheets 1050 3003 1.2mm to 3mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords