040 Aluminum Coils for Aluminum Profiles of Automated Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminum Profiles for Roller of Automate Equipment Description

Aluminum Profiles for Roller of Automate Equipment is one semi-finished aluminium material. The alloy AA6063 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminum Profiles for Roller of Automate Equipment

Aluminum Profiles for Roller of Automate Equipment | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminum Profiles for Roller of Automate Equipment

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminum Profiles for Roller of Automate Equipment

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminum Profiles for Roller of Automate Equipment

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

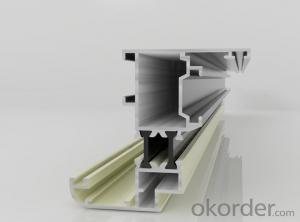

6. Image of Aluminum Profiles for Roller of Automate Equipment

7. Package and shipping of Aluminum Profiles for Roller of Automate Equipment

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils used in the automotive industry?

- Due to their numerous advantages over traditional materials, aluminum coils play a crucial role in the automotive industry. They are widely used in various parts and components of vehicles, enhancing performance, improving fuel efficiency, and reducing overall weight. A primary application of aluminum coils in the automotive industry is in the manufacturing of heat exchangers, such as radiators and condensers. Aluminum's excellent thermal conductivity enables efficient heat transfer, regulating engine temperature and optimizing performance. By incorporating aluminum coils in heat exchangers, vehicles can achieve better cooling efficiency, preventing engine overheating and maintaining optimal operating conditions. Furthermore, aluminum coils are utilized in the production of air conditioning systems, specifically in the condenser and evaporator units. These coils have excellent heat exchange capabilities, enabling efficient cooling or heating of the vehicle's interior. As a result, vehicles equipped with aluminum coil-based air conditioning systems can provide a comfortable environment for passengers while minimizing energy consumption. Moreover, aluminum coils are used in constructing lightweight body panels and structural components like doors, hoods, roofs, and chassis. Aluminum's high strength-to-weight ratio makes it ideal for reducing vehicle weight without compromising structural integrity. This weight reduction leads to improved fuel efficiency, reduced emissions, and enhanced performance in acceleration, handling, and braking. Additionally, aluminum coils find application in producing electrical systems in automobiles. Their excellent electrical conductivity makes them suitable for wiring harnesses, connectors, and other electrical components. The use of aluminum coils in these systems ensures efficient transmission of electrical signals and reduces overall vehicle weight, contributing to improved fuel economy. In conclusion, aluminum coils are extensively used in the automotive industry for various purposes, including heat exchangers, air conditioning systems, body panels, and electrical components. The exceptional properties of aluminum, such as thermal conductivity, strength-to-weight ratio, and electrical conductivity, enable automakers to produce lighter, more efficient, and environmentally friendly vehicles.

- Q: I'm wondering if there is a resin/molding material that can withstand the heat of melted aluminum for casting parts. I know that sand casting is the 'norm' but is there anything else? I'd rather not have to pack sand every time I want to cast a part.Thanks!

- One common mold material for metal casting is plaster mixed with silica sand to give it more strength. It needs to be completely (like heated) dry before you use it, but it is actually more work than sand casting but it gives a better finish. There are some rubber materials which can withstand the heat of casting pewter, but the melting point of pewter is so much lower than aluminum that I am sure those won't work for aluminum. I think you are pretty much stuck with sand for the easiest method.

- Q: This question asks for the method to calculate the volume of an aluminum coil given its size.

- <p>To calculate the volume of an aluminum coil, you need to know its dimensions: the length of the coil, the diameter of the wire, and the number of turns. The volume can be calculated using the formula for the volume of a cylinder, adjusted for the coil's shape. The formula is: Volume = 蟺 * (diameter/2)^2 * length * number of turns. Here, 蟺 is approximately 3.14159, diameter is the diameter of the wire in the coil, length is the total length of the coil, and the number of turns is the number of times the wire is wound around the coil. This formula gives you the total volume of the aluminum in the coil.</p>

- Q: How are aluminum coils used in the production of power transmission lines?

- Aluminum coils are used extensively in the production of power transmission lines due to their unique properties and benefits. These coils are typically made from high-quality aluminum alloys that offer excellent conductivity, strength, and corrosion resistance. One key application of aluminum coils in power transmission lines is in the manufacturing of overhead conductors. These conductors are used to transmit electrical energy from power plants to substations and distribution networks. Aluminum coils are used to create the conductive core of these overhead conductors, as aluminum has a much lower resistance compared to other metals like copper. This low resistance allows for efficient transmission of electricity over long distances, minimizing energy loss and improving overall system performance. Moreover, aluminum coils are lightweight compared to copper coils, making them easier to handle and install. This characteristic significantly reduces the costs associated with transportation, installation, and maintenance of power transmission lines. As a result, aluminum coils have become the preferred choice for overhead conductors in power transmission systems worldwide. Furthermore, the corrosion resistance of aluminum coils ensures long-term durability and reliability of power transmission lines. Aluminum naturally develops a protective oxide layer that prevents further corrosion, even in harsh environmental conditions. This corrosion resistance extends the lifespan of the transmission lines, reducing the need for frequent repairs or replacements. In summary, aluminum coils play a crucial role in the production of power transmission lines. They enable efficient electricity transmission over long distances, reduce costs associated with installation and maintenance, and provide long-lasting corrosion resistance. With these advantages, aluminum coils have become a widely adopted solution in the power industry to enhance the performance and reliability of power transmission systems.

- Q: How do you clean and maintain aluminum coils?

- To clean and maintain aluminum coils, start by turning off the power to the unit. Then, use a soft brush or vacuum cleaner to remove any dust, dirt, or debris from the coils. Next, mix a solution of mild detergent and warm water, and apply it to the coils using a soft cloth or sponge. Gently scrub the coils to remove any stubborn stains or grime. Rinse the coils thoroughly with clean water and allow them to dry completely before turning the power back on. Regularly inspect and clean the coils to ensure proper functioning and longevity of the aluminum coils.

- Q: Are aluminum coils fire-resistant?

- Aluminum coils possess fire-resistant qualities due to their high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and their inability to burn, rendering them non-combustible. This specific characteristic allows for the utilization of aluminum coils in various applications, particularly in sectors where fire resistance is of utmost importance, such as building construction, electrical wiring, and HVAC systems. Moreover, the remarkable heat conductivity of aluminum facilitates rapid heat dissipation, thereby minimizing the risk of fire incidents. Nevertheless, it is crucial to acknowledge that although aluminum coils themselves exhibit fire-resistant properties, they may be incorporated into systems alongside other components that might not share the same level of fire resistance. Consequently, it is essential to consider the entirety of the system and adhere to proper fire safety regulations and guidelines to ensure comprehensive fire safety precautions.

- Q: Are aluminum coils suitable for construction applications?

- Yes, aluminum coils are suitable for construction applications. Aluminum is a lightweight and durable material that is widely used in the construction industry. Aluminum coils are often used for roofing, siding, gutters, and other exterior applications due to their resistance to corrosion and their ability to withstand harsh weather conditions. They are also easy to install and maintain, making them popular among contractors. Additionally, aluminum coils can be painted or coated to enhance their aesthetic appeal and to match the overall design of a building. Overall, aluminum coils are a reliable and cost-effective choice for construction applications.

- Q: How are aluminum coils protected against corrosion?

- Aluminum coils are protected against corrosion through various methods such as applying protective coatings, anodizing the surface, using corrosion-resistant alloys, and implementing proper maintenance practices.

- Q: I go on a trip once a year with a group of lets say 10 people, we go for 7 nights and consume on average approx 120 cans of beer each (throughout the week). We have a fire burning the whole time in a hole that we dig approx 1ft deep, then we dispose of each can in the fire and let them melt down never thinking about them again. That's approx 1,200 cans that melt in the one fire hole.Will the aluminum have an affect on the soil? does anyone know what sort of damage this can cause? and for what distance / area around the fire might be affected?The theory amongst the group is that cans do not hurt anything so that's why they take cans instead of glass.Thanks

- Aluminum is very reactive in air and will form a layer of aluminum oxide around the outside of any piece. This oxide layer is very stable which is why aluminum doesn't corrode. Since your block of aluminum will be totally oxidized being in a fire, it's inert and just going to sit in the hole for the foreseeable future. The burning paint might not be healthy to breath but that's about the only hazard. Most common soil is a mixture of aluminum, carbon and silica compounds anyways so you aren't even adding anything particularly exotic. Alternatively, you could bring along a couple fifths of whiskey. It's lighter and has less packaging so it's the environmentally friendly way to get drunk.

- Q: Can aluminum coils be used in the manufacturing of furniture?

- Yes, aluminum coils can be used in the manufacturing of furniture. Aluminum is a lightweight and durable material, making it ideal for furniture production. It is commonly used in the construction of outdoor furniture, as it is resistant to rust and corrosion. Aluminum coils can be formed into various shapes and sizes to create different furniture pieces. Additionally, aluminum can be easily customized and finished with different coatings or paint to match any desired aesthetic. Overall, aluminum coils are a versatile and practical choice for furniture manufacturing.

Send your message to us

040 Aluminum Coils for Aluminum Profiles of Automated Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords