027 Aluminum Coil for Aluminium Profile Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Coated Coil for Aluminium Profile Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coated Coil for Aluminium Profile:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

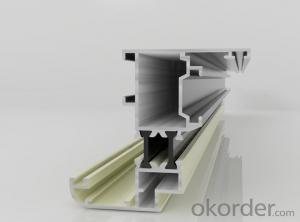

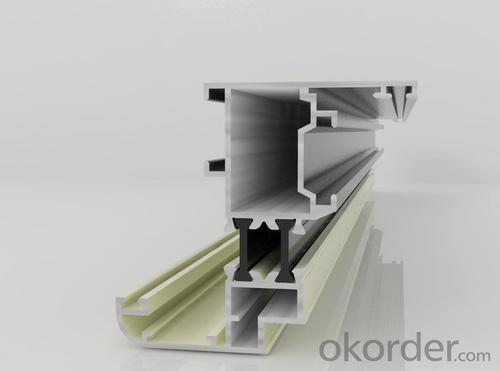

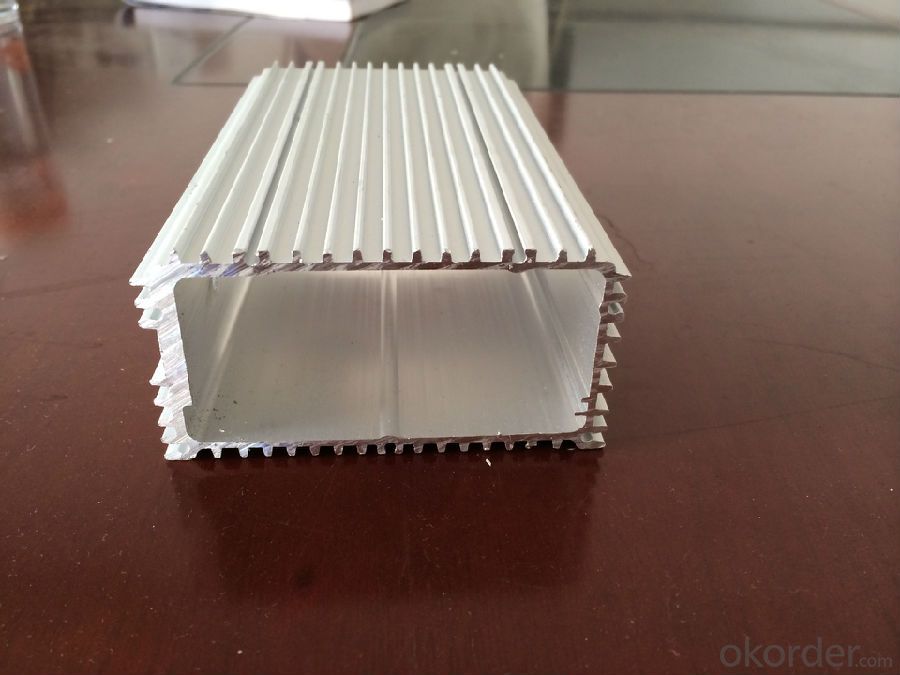

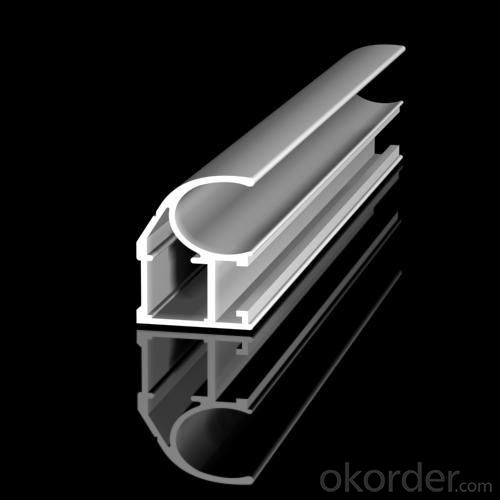

Images of the Aluminium Coated Coil for Aluminium Profile:

Aluminium Coated Coil for Aluminium Profile Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Other than alloys. I'm trying to think of a way I can make an aluminum knife that will hold an edge. One group of researches say they used 60 metric tons of force to realign the molecular structure and give the metal strength equal to steel. I don't have a 60 ton press aha. Would heat treatment plus 10 tons of pressure repeated have a similar affect?

- Aluminum bronze is used commercially to make non-sparking knives. Why try to reinvent the wheel? I'm trying to think of a way I can make an aluminum knife that will hold an edge. You can strengthen aluminum by either cold working or heat treating a suitable alloy, but it will never be anything close to a good steel knife. Would heat treatment plus 10 tons of pressure repeated have a similar affect? No. Assuming that you are talking about the article linked to below: - you would have to duplicate the alloy process, even then you could only make a small thin sheet. They used a heat treatable alloy. The process involves torsional strain under 60 metric tons per square centimeter compression. How big a press do you think you would need for a knife size blank? And remember, you have to apply torsional cold work while compressing it. -Their results ( 1 gPA YS 5% elongation in a very thin sheet) don't look that great compared to a good knife steel. Or a good titanium knife.

- Q: Tossing away an aluminum can wastes as much energy as pouring out half of that can’s volume of gasoline.what does that mean?

- Aluminum cans are made of energy so there is as much energy in the can as in half a can of gasoline.

- Q: This question asks for methods to determine the age of an aluminum coil, distinguishing between new and old.

- <p>To determine if an aluminum coil is new or old, you can look for several indicators: the surface condition, such as scratches or signs of wear; the quality of the protective coating, if any, which may degrade over time; the manufacturing date or batch number, if available; and the overall appearance and shine. New coils typically have a smooth, shiny surface with no significant scratches or dents, and a consistent protective coating. Old coils may show signs of oxidation, discoloration, or other forms of degradation. Additionally, testing the coil's physical properties, such as tensile strength, can provide clues about its age, as these properties can degrade over time.</p>

- Q: Please tell me the the size of the piece of aluminum that you give the weight messurements.

- 2.7 grams per cubic centimeter at room temperature it's a 2.75 on the Moh's hardness scale. There is a ton of info on Aluminum available on wikipedia.

- Q: What are the differences between aluminum coil 3003h24 and 3a21h14?

- The mechanical property references of rolled plate 3003 H24and 3A21 H14 are as follows: 3003 H24--Rm/MPa≧140-180;Rp0.2/MPa≧115;A(%)≧1-5(thickness 0.2mm-4.5mm)3A12 H14--Rm/MPa≧145-215;A(%)≧6

- Q: How does aluminum ingot be processed to aluminum coil (aluminum sheet)?

- First it should be made into blank and then put on the rolling mill.

- Q: How do aluminum coils perform under high-temperature applications?

- Aluminum coils perform well under high-temperature applications due to their high thermal conductivity and excellent heat dissipation properties. They can effectively withstand elevated temperatures without deforming or losing their structural integrity. Moreover, the corrosion resistance of aluminum makes it a suitable choice for applications where high temperatures and potential exposure to harsh environments are involved.

- Q: What are the different yield strengths of aluminum coils?

- The yield strength of aluminum coils can vary depending on the grade or alloy of aluminum used. Aluminum is available in various grades, such as 1100, 3003, 5052, and 6061, among others. Each grade has its own unique properties, including different yield strengths. For instance, the 1100 grade of aluminum has a relatively low yield strength of about 12,000 psi (pounds per square inch). This grade is often used for general-purpose applications where high strength is not a primary requirement. On the other hand, the 6061 grade of aluminum has a significantly higher yield strength of around 35,000 psi. This grade is commonly used in structural applications or where higher strength and durability are needed. It's important to note that the yield strength of aluminum coils can also be influenced by factors such as the thickness and temper of the material. Thicker coils generally have higher yield strengths, while different tempering processes can further enhance the strength and other mechanical properties of the aluminum. In summary, the yield strength of aluminum coils can vary depending on the grade, thickness, and temper of the material. It is essential to consider these factors when choosing the appropriate aluminum coil for specific applications to ensure optimal performance and structural integrity.

- Q: And what are the advantages/disadvantages of steel aluminum in building cars?Which would be better for building cars?

- Erm im no expert, bt I dont think aluminum is very strong, thus not very safe for a car!

- Q: What are the common industry standards for aluminum coil specifications?

- Various organizations, such as the Aluminum Association (AA) and the American Society for Testing and Materials (ASTM), establish the common industry standards for aluminum coil specifications. These standards guarantee consistency and uniformity in the manufacturing and utilization of aluminum coils in different industries. The Aluminum Association (AA) is responsible for defining the standards for aluminum alloys and their corresponding temper designations. By classifying aluminum alloys based on their chemical composition and mechanical properties, the AA enables manufacturers to produce coils with specific characteristics suitable for different applications. For instance, AA 3003 is commonly utilized for general-purpose coils, while AA 5052 is preferred in marine applications due to its superior corrosion resistance. Aside from alloy classification, the AA also provides guidelines regarding coil dimensions, tolerances, and surface finishes. These specifications ensure that aluminum coils adhere to the required dimensions and quality standards, facilitating their integration into various manufacturing processes. The American Society for Testing and Materials (ASTM) also holds a significant role in establishing standards for aluminum coil specifications. ASTM offers guidelines for different tests and procedures to assess the quality and performance of aluminum coils. These tests encompass mechanical property evaluations, such as tensile strength and elongation, as well as assessments of surface finish, corrosion resistance, and dimensional stability. Furthermore, specific industries may have their own set of standards for aluminum coils used in their applications. For instance, the automotive industry could have industry-specific standards to ensure compliance with particular performance requirements in vehicle manufacturing. In conclusion, the common industry standards for aluminum coil specifications cover alloy designation, dimensional tolerances, surface finishes, and mechanical properties. Adhering to these standards guarantees consistency, quality, and compatibility across diverse industries and applications.

Send your message to us

027 Aluminum Coil for Aluminium Profile Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords